| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Высокое качество SMT PCB паяльный конвейер оплавляющая печь

- Категория: >>>

- Поставщик: Beijing Glichn S&T Development Co. Ltd.

Сохранить в закладки 1346310343:

Описание и отзывы

Характеристики

Features:

The heating system is unique , advanced and long-life.

High efficiency and energy-save nickel cauterize heating pipe is used in heating system(replacement

within one year), strong hot air cycle structure , making PCB and components heating equally, high

efficiency and rapid heating speed.

The intelligent micro-computer precision controller (replacement within one year), through intelligent

operation of PID, control heating automatically , blurry controlling function can respond to thermal

changing with furthest speed ,and then make temperature stable by inner controlling.Modularization

design , easy to repair and assembly.

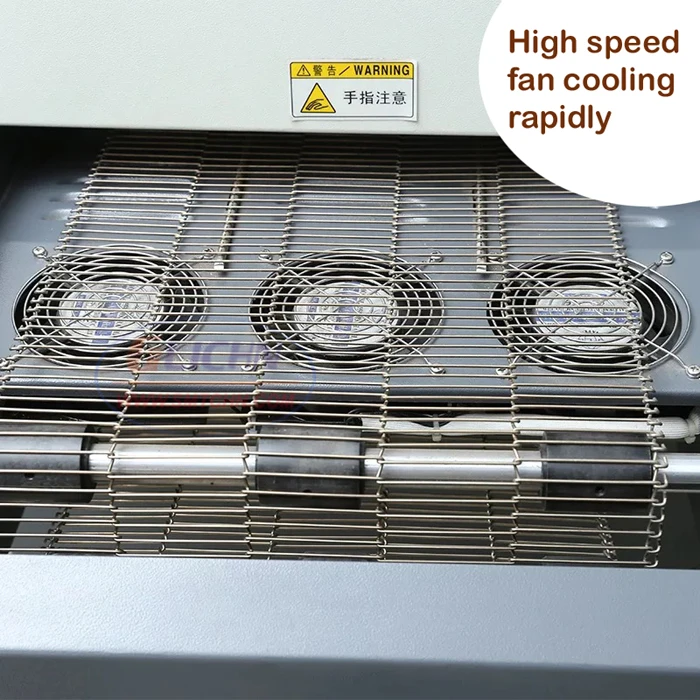

Import and high temperature and high speed motor be used (replace within one year), stable operation,

small tremble, small noise. Top body can be start wholly to make hearth clean. The efficiency be

improved greatly, extending the using time. The heating system use import components to make sure

high stability and reliability of all system.

import driver is used in the reliable and stable transmission system( replacement within one year),

matching turbine decreasing driver STK with 1:150 , stable operation, speed range is from

0-2000mm/min.

independent roller structure and splint support combined with stainless steel net chain , stable operation

special stainless steel net chain, it is durable and wearable. It can’t change for long time.

Stable and reliable electronic controller system.

Conveyor Reflow Oven

Packing method:

1)Standard box package for light and small item;

2)Strong wood package for heavy and large equipment;

Shipping way:

1)By air ,for sample and small package ,wordwide express like DHL,UPS,FedFX,EMS....

2)By sea, for large package and quantity;

3)By car or other ways as customer requested;

GLICHN found in 2010,Specializing in SMT equipment manufacturing services and sales of peripheral products. Factory is located in shunyi district of Beijing and shenzhen baoan district

SMT class:pick and place machine,small and middle size reflow oven, manual and semi-automatic solder paste printer,PCB loader and unloader,PCB magazine rack,SMD component counter,solder paste and chip production line etc.

THT Class:wave soldering machine, Spray tin stove,cut foot and forming machine,Plug-in production line etc

Others :Spin coater,Dispensing machine,nozzles,feeder,belt ,driver, motor,cylinder,High temperature tape,valve,etc

1. We’ll have a good check and a test before shipping out.

2. We provide you the friendly English User manual or the operating videos for free;

3. 24 hours technical support by email or Skype or Trade Manager or Calling.

4. 1 year machine parts free warranty;

5.Engineers available to service machinery overseas.

1 set machine, mixed order is also welcome.

a. How can I buy this machine from you? ( Very easy and flexible !)

b.Consult us about this product on line or by e-mail.

c. Negotiate and confirm the final price , shipping , payment methods and other

terms for machine.

d.Send you the proforma invoice and confirm your machine order.

e. Make the payment according to the method put on proforma invoice.

f. We prepare for your machine order in terms of the proforma invoice after confirming your full payment. And 100% quality check before shipping.

g.Send your machine order by air or by sea.

Why choose us ?

a. Best price & Best shipping & Best service

b. Ten years of experience in research and development production and sales

c. Eight years of alibaba gold supplier

d. Trade assurance

Похожие товары

Широко используемый декоративный шерстяной ковер, оптовый Производитель роскошных стильных индивидуальных размеров, доступные коврики

Слинг изогнутые швы, одежда для сна, 1 шт. Лидер продаж v образным вырезом сексуальное женское белье кружевной комплект нижнего белья с бюстгальтером для полных женщин 2021

Пользовательские кроссовки для тренажерного зала, роскошная обувь для фитнеса, кроссовки Fen diS, подходят к атлетической повседневной обуви для мужчин, мужская обувь

Высококачественный спиральный пружинный Выдвижной USB-кабель типа c для передачи данных для samsung

Система вентиляции для складов, промышленный охладитель для пустыни, Испарительный воздухоохладитель

Пигментный Порошок Loman/Двуокись титана рутил по хорошей цене за тонну

Полые стальные США прямоугольные стальные 40x80 RHS SHS стальные трубы

Новые поступления

Новинки товаров от производителей по оптовым ценам