Горячая Распродажа печь для карбонизации бамбукового угля 0086

- Категория: >>>

- Поставщик: Gongyi Hengyuan Industry Co. Ltd.

Сохранить в закладки 1465911840:

Описание и отзывы

Характеристики

Hot sale bamboo charcoal carbonization furnace

Skype evazhao06 Whats app 0086 15617575581

Brief introduction of bamboo charcoal carbonization furnace

The bamboo charcoal carbonization furnace, also called environmental continuous gasification carbonization equipment, is used to convert the wood or agro waste materials containing carbon to charcoal powder under high temperature. The raw materials goes through the destructive distillation process in the oxygen-free environment to reach high carbonization degree.

Bamboo charcoal carbonization furnace is suitable for charcoal wood, coconut shell, bamboo

etc. It consists of one main furnace, three inner baskets and hoisting tools, about 4 tons of

weight, packing size for 13 cubic meters. It is the inner pot of wearing parts, ordinary material

the inner basket service life is 2 years, made the inner basket boiler plate 8 mm thickbase,

service life can reach 3 years. Charcoal time is 8 to 12 hours, cooling time 8 to 10 hours.

Technical parameter of bamboo charcoal carbonization furnace

Main structure | One main furnace and three inner basket and necessary hoisting tool. |

Carbonization furnace | Different raw material have different carbonization time; about is 8-10 hours. |

Cooling time | 5-8 hours with the cooling time increase ,the carbonization effect more better. |

Capacity | Deal with 4.5-6 ton raw material,get 3-3.5 ton charcoal. |

Weight | One set furnace is 4 tons. |

Inner stove | The around steel thickness is 6mm, the bottom steel is boiler steel 8mm. |

Three Inner basket diameter | 1460mm, 1430mm and 1400 mm, height 1.52mm |

Three inner basket stove volume | 2.54CBM 2.43CMB and 2.34CBM |

Semi-finished product of bamboo charcoal carbonization furnace

Our bamboo charcoal carbonization furnace with high quality refractory brick and plate as the outer wall thickening, increased the using time and the effect of carbonization stove. Our company has many years experience in production and sale of charcoal furnace and its production line, our products are welcomed by customers around the world.

Working principle of bamboo charcoal carbonization furnace

The machine takes full advantages of CO, methane, hydrogen and other flammable gas produced during the carbonization process and adopts the high technique of gas recovery, purification and recirculating combustion. It not only solves the air pollution caused by th heavy smoke during carbonization, but also supplies the heat energy needed by the production. Such design makes the self-sufficiency real, meanwhile, improves the continuity and economical efficienry to make full use of agroforestry waste ad change them to valuable. It is the perfect choie to suply the short of traditinal energy, also it the good raw materials for activated carbon.

Main parts of bamboo charcoal carbonization furnace

Main parts include: stainless valves, main furnace, inner basket, cooling tan and ect.

Raw material and final product for bamboo charcoal carbonization furnace

Wood chips, wood branches, sawdust, coconut shell, rice husk, straw, macadamia shells, and etc.

What is bamboo charcoal carbonization furnace working process?

A.Heating process: after putting the inner basket into the furnace, we need to hest furnace up to

80-120mins, we could use gas or biomass waste as fuel, when the temperature get around

280-300℃, we stop heating.

B.Carbonzaiton process: after doing the sealing works, the raw material inside beagin to

pyrolysis, it will produce gas at this period, so we need heating in this process, the carbonization

time about 8-10 hours.

C.Cooling process: after arbonization, we need to take the inside furnace out, let it cool by

natural way, cooling time longer, it is better for charcoal quality.

D.After taking the inner basket out, we need to put other basket inside, this is cycling process.

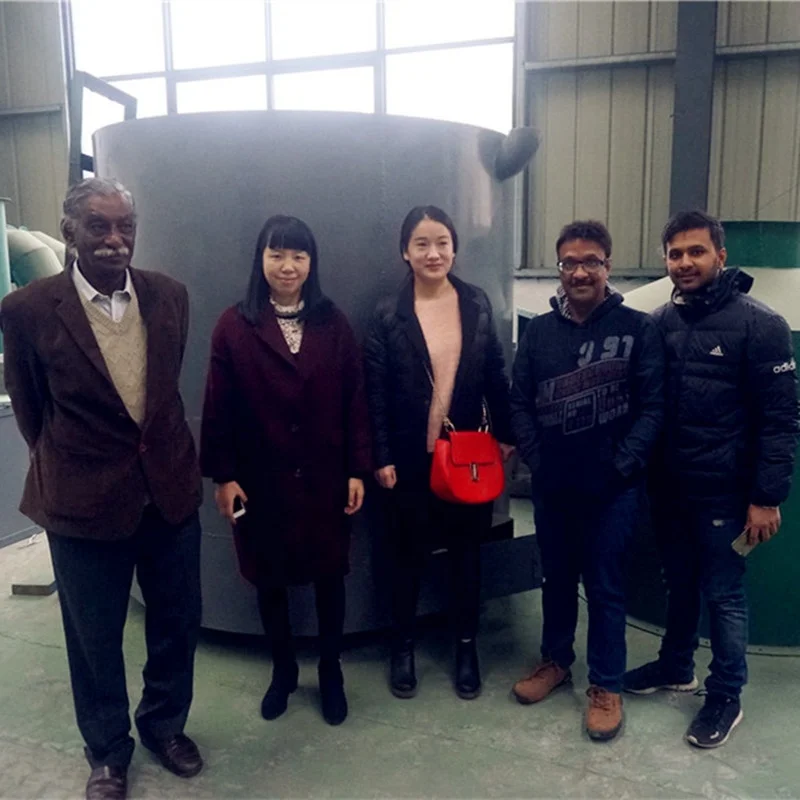

Shipment and clients visited our factory pictures for bamboo charcoal carbonization furnace

Advantages of bamboo charcoal carbonization furnace

1.Almost all kinds of agriculture and forestry waste can be used.

2.High efficiency and enviroment, shorter carbonizing time.

3.Easy to operate.

If you are interested in this bamboo charcoal carbonization furnace, please contact with me freely as the followings:

Похожие товары

Электрический медный Болтовой соединитель от производителя

2 4 3 5 7 10 дюймов рекламное приглашение на свадьбу Бизнес ЖК Видео поздравительная открытка видео

OEM/ODM водонепроницаемый пыленепроницаемый огнестойкий крошечный GPS-Трекер Смарт приложение сигнализация компания транспортное средство GPS трекер персональный автомобиль Gps трекер

Оптовая продажа натуральная итальянская кожа для сумок и

Низкоскоростная машина для производства бумажных стаканчиков YG прямо с

Новинка 2020, высококачественный Usb-кабель Foxconn длиной 1 м/3 фута, кабель для передачи данных, зарядный кабель для Iphone 8X7

Кодовый замок на 4 цифры по ценам от производителя Открытый водонепроницаемый замок для школы гимнастический зал отделение для хранения, спортивный шкафчик

Новые поступления

Новинки товаров от производителей по оптовым ценам