Оборудование для формования угльного порошка с полной производственной линией

- Категория: >>>

- Поставщик: Gongyi Hengyuan Industry Co. Ltd.Gongyi Ltd.

Сохранить в закладки 1467414427:

Описание и отзывы

Характеристики

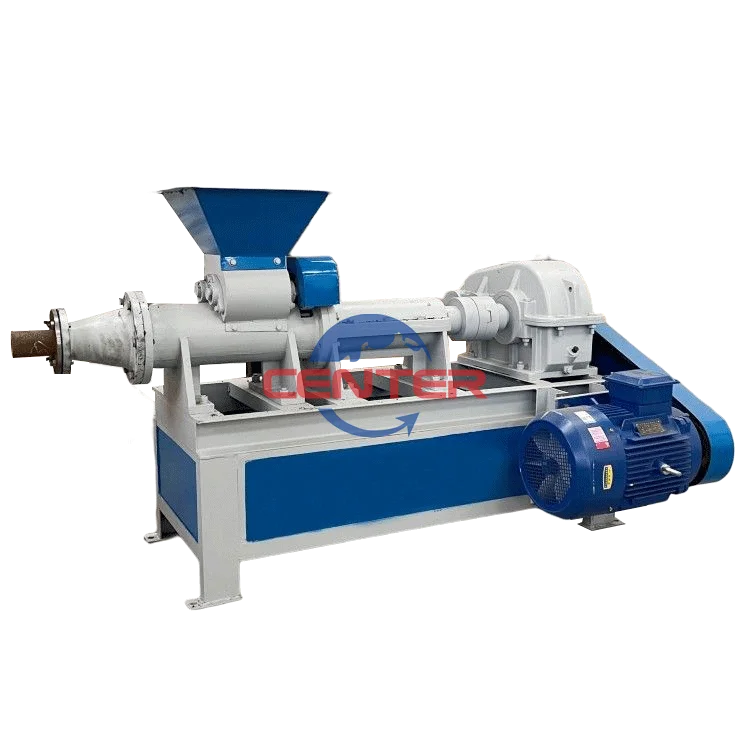

Coal powder moulding equipment with complete

production line

Brief introduction of coal powder moulding equipment

1.Coal powder moulding equipment is also called powerful pressure ball press machine, dry

powder ball press machine, the roller ball press machine, goose egg molding machine and so on.

2.The machine has the characteristic of high molding pressure, main engine RPM adjustable and

a spiral feeding device.

3.The ball press machine is mainly used in coal forming; dry powder molding; desulfurization

gypsum molding; coke powder molding; scrap iron and various metal mineral powder molding

and so on.

Type | Capacity | Power | Weight | Size (L*W*H) | Roller materials |

HY-290 | 1-2t/h | 7.5kw | 800kg | 1.32*1.23*1.52m | 65Mn 2 rollers |

HY-360 | 3-4/h | 11kw | 1000kg | 1.45*1.47*1.75m | 65Mn 2 rollers |

HY-430 | 6-8t/h | 15kw | 3800kg | 1.45*1.52*1.75m | 65Mn 4 rollers |

HY-500 | 8-10t/h | 37kw | 5800kg | 1.75*1.78*2.43m | 65Mn 4 rollers |

HY-650 | 12t/h | 45kw | 6500kg | 2.65*2.70*2.43m | 65Mn 4 rollers |

HY-750 | 16t/h | 55kw | 8500kg | 3*2.9*2.43m | 65Mn 4 rollers |

HY-850 | 18-20t/h | 75kw | 13000kg | 3.2*3*2.45m | 65Mn 4 rollers |

HY-1000 | 23-25t/h | 110kw | 17000kg | 3.5*3*2.8m | 65Mn 4 rollers |

Raw material of coal powder moulding equipment

1.Raw materialsize should be smaller than 5mm. (If larger, crusher will be used).

2.The best moisture for briquetting is 6-10%.

3.The raw material including: mineral power, coal powder, charcoal powder, iron powder and ect.

Final product of coal powder moulding equipment

Final products burning situation of coal powder moulding equipment

Features of coal powder moulding equipment

1) Operate easily and stably;

2) The machine can produce products with different shapes and specifications by changing the mould;

3) It can make all sorts of alien mould according to the users needs to meet the demands of the market.

1.One year’s guarantee completely

2.Accept testing machines before delivery

3.Online technical supporting 24 hours

4.We will arrange our technical stuff to your factory for installation guide

Похожие товары

Небольшой пресс для прессования каолиновой глины

Китай, Лидер продаж, широко используемая древесная пеллетная горелка на биомассе 200 квт-5600 кВт с CE

Станки для производства брикетов древесного угля

Высокое Качество Дешевая Цена Опилки древесный уголь брикетировочная машина для продажи

Китайский производитель прямая продажа экструдер для Брикетирования Угольной Пыли Типа 140 1-2 т/ч машина производства угольных стержней брикета порошка угля

Древесный газификатор

Непрерывная Обжиговая печь для защиты окружающей среды

Новые поступления

Новинки товаров от производителей по оптовым ценам