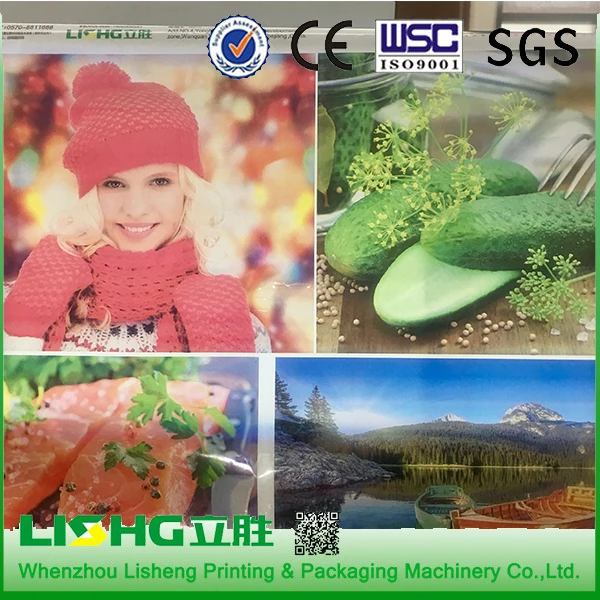

Китай производитель костюм для мальчиков 3 цвета 4 6 видов цветов флексографическая печатная машина Flexo сумка машин печати на бумажных нетканые hdpe БОПП пакеты упаковки пищевых продуктов

- Категория: Flexographic Printers >>>

- Поставщик: Wenzhou Lisheng Printing & Packaging Machinery Co. Ltd.

Сохранить в закладки 1585178071:

Описание и отзывы

Характеристики

Product Application

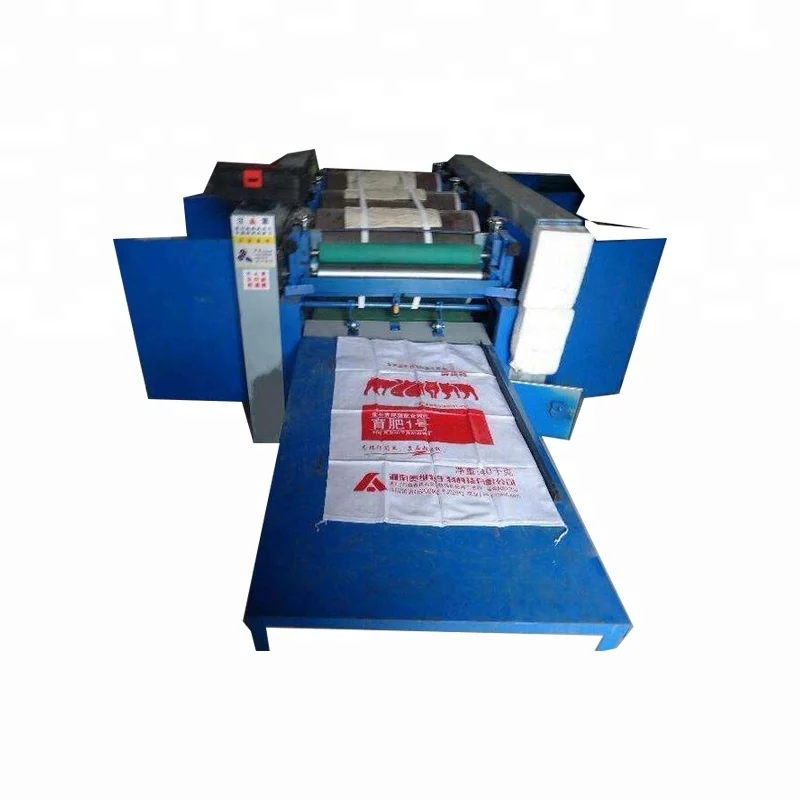

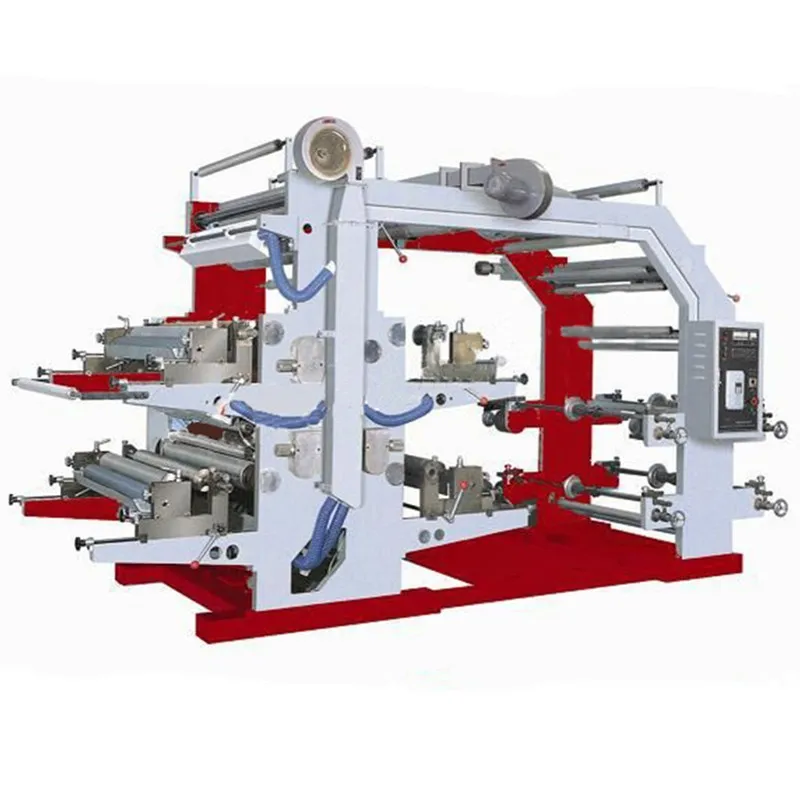

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll paper etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

SUITABLE MATERIAL | ||||||

PAPER | Kraft paper:40-200g/㎡ single-sided coated paper:30-200g/㎡ copy paper:15-200g/㎡ firecrackers and paper:40-200g/㎡ silicone paper:50-200g/㎡ paper money and incense:25-200g/㎡ coated paper:30-200g/㎡ dust-free paper:25-200g/㎡ release paper:40-200g/㎡ composite paper:30-200g/㎡ | |||||

FABRIC | ||||||

FILM | PVC:10-120g/㎡ OPP:10-120g/㎡ PE :10-120g/㎡ PET:10-120g/㎡ BOPP: 10-120g/㎡ CPP: 10-120g/㎡ | |||||

Main Features

1) Central impression type printing machine with better color registration. Due to the big drum, the printed material is

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

Feeding Material Part

1.Automatic stop machine when break the material. When machine stop, keep tension and avoid the material loose or line deflection.

2.Single unwinder system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.

3.Roller core diameter: 76mm

4.Discharge maximum diameter: 1000mm

Printing Sections

1.Printing consists of: central drum, plate roller, ceramic anilox roller, single doctor blade and chamber doctor blade.

2.Plate roller circumference: 280-1000mm.

3.Print material: resin plate or rubber plate.

4.Transmission: central drum with big gear drive the printing station.

Drying System

1.Use hot air drying, intelligent constant temp control.

2.Drying units are installed after the printing units, and air volume can be adjusted by independent damper/panel.

3. The dryting system after the printing it is about 30kw.

Rewinding Part

2.Roller core diameter: 76mm

3.Discharge maximum diameter: 1000mm

PS: Above configurations just for your reference. Know more details please connect with us! Thanks and best regards!

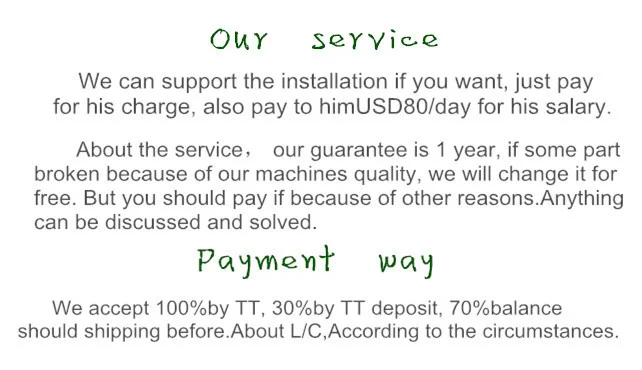

Delivery Time And Payment Terms

Within 45 working days after recieve 30% T/T deposit, then the balance be paid after satisfy test in seller's factory before delivery.

4 Colors CI Printing Machine

6 Colors CI Printing Machine

8 Colors CI Printing Machine

Похожие товары

Онлайн флексографская печатная машина одного цвета

Одноступенчатая машина для флексографской печати

Флексографская печатная машина, высококачественный четырехцветный флексографический принтер, пластиковая пленка, печать на флексографской водной основе, чернильная печать, изображение

Четырехцветная средняя-высокоскоростная флексографская печатная машина

Полностью автоматическая машина для ткани упаковочная этикетка рулон офсетная печатная машина

Принтер a3 для тканей, одежды, текстиля, принтер для футболок, Принтер dtg, машина для печати футболок

Высокое качество 6 цветов флексографская печатная машина в Мексике пластиковая пленка Новые 2 Цвета Флексографские печатные принтеры

Новые поступления

Новинки товаров от производителей по оптовым ценам