Электрический тип сопротивления Вращающаяся печь для спекания порошка и гранул

- Категория: >>>

- Поставщик: Luoyang Juxing Kiln Co. Ltd.

Сохранить в закладки 1600051358844:

Описание и отзывы

Характеристики

Product Description

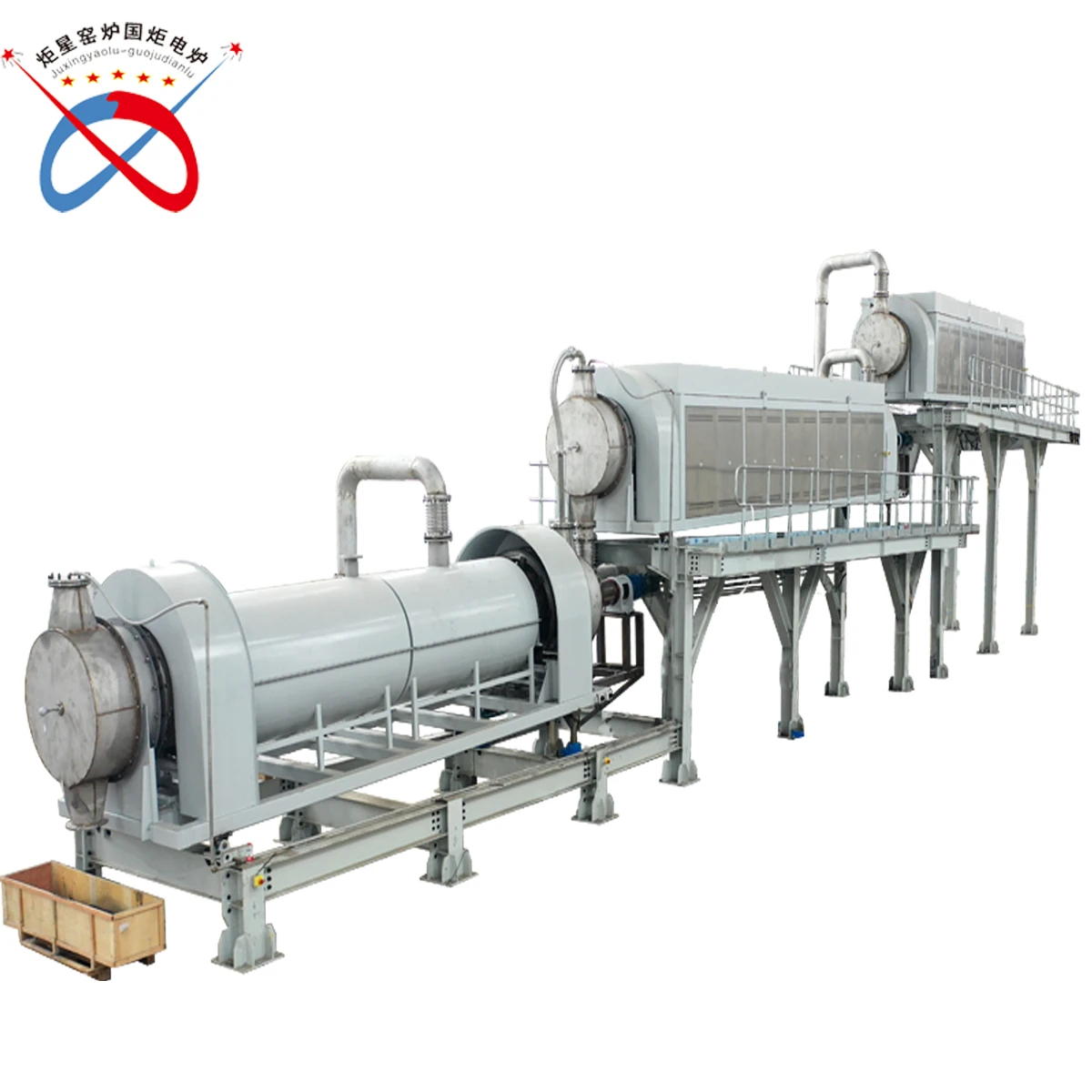

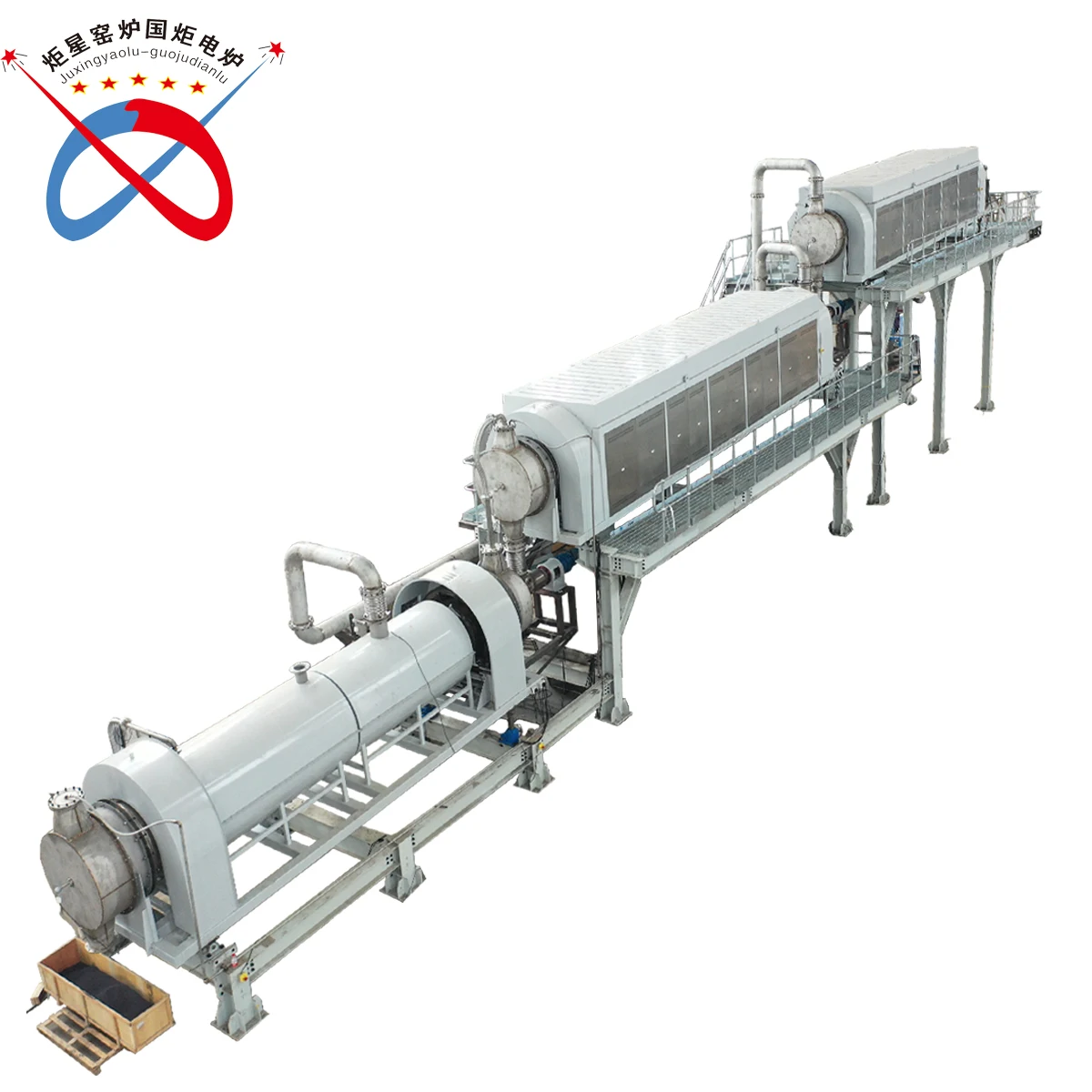

Product Name | Electric Resitance Heating Method Rotary Kiln |

Material | Aluminum Fiberboard(Refractory materials) + Sic&Mosi2 (Heating elements)+Mullite bricks |

Loading Capacity | Stanard 3-5 Ton (Special requirements can be customize) |

Platform Moving Method | Electric drive |

Tube Diameter | Less then 1200mm |

Heating zone length | Depends on customer requirements |

Package | Composite wood packaging (fumigation free), or other wooden export packaging. Ensure the safety of the goods. |

Remark | Part of the function and description are not listed, if the customer is interested, you can write to inquire at any time. |

Abstract

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. The basic components of a rotary kiln are the shell, the refractory linings, support tires (riding rings) and rollers, drive gear, and the heating elements. GWL has designed different solutions according to the needs of different customers. GWL is particularly good at sintering powder and particles containing water and organic matter in products with relatively rich production experience.

WorkFlow

The rotary kiln's tube is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its longitudinal axis(Controlled by a rotating motor). The process feedstock is using the screw feeder fed the upper end of the cylinder.As the kiln rotates, material gradually moves down toward the lower end, and may undergo a certain amount of stirring and mixing. Using the electric resistance heating method to heating the materials, and once the process completed, the material can be discharged to the cooling section.

Rotary Kiln Working Principles

Conveying materials of different properties through screw feeder (variable frequency control) into rotary kiln's tube,The rotary kiln itself will be installed with a certain tilt Angle(Maximum 5 Degree),As the tube rotates, the material will automatically fall into the tube and pile up at the end.Customers can make corresponding Settings according to their own heating process. The furnace will heat up by itself according to the parameters set. After heating up, the discharging operation can be carried out.If the discharge temperature is too high, the tail can be considered to add cooling section (water spray, or other cooling methods can be customized).

Electric Screw Feeder

Material conveying uses a spiral feeding device, The shaft-less feeder can be used for materials with high humidity. Avoid material adhesion, blocking the feeding port.Feeding speed can be controlled by variable frequency control.Through the space between each stage of the spiral, the material is fully moved to ensure the convenience of material transportation to the heating tube.The tilt Angle and rotation speed of the furnace tube can determine the material moving time and discharging speed.

Rotary Tube Manufacturing Process

GWL can provide different combinations of furnace tube materials according to customers' use temperature requirements. General radiant tube diameter should not exceed 1.2m (The range of electric radiant heat). The welding of the furnace tube meets the European Union WPS WPQ standard.There are flipper board welded in the furnace tube to facilitate the materials to be heated and mixed. After high temperature sintering, the material will not adhere to the furnace tube, it also can ensure the material is heated uniformly.

Cooling Method

GWL is more inclined to provide continuous production rotary kiln to customers, so the cooling section of the rotary kiln is indispensable. After a long period of one section furnace treatment or multi-section treatment furnace, The product still has a certain temperature, which can recover the waste heat through the cooling section, and reduce the temperature of the material by means of air cooling or cooling water spraying, so that the material can be packaged and loaded directly.

Electric control cabinet

According to customers' different budgets, GWL provides different types of electric control cabinet combinations, with protection classes ranging from IP46 to IP65, to avoid the adverse effects of dust and dust in the air on the electric control cabinet. The selection of electrical components ranges from the mainstream first-tier and second-tier brands, from Siemens and ABB to domestic brands such as Anton and yudian.Different customer groups, can meet customer needs.

Control system

GWL offers a wide range of control systems, from basic touch screen controls to fully automated controls in industry 4.0.In the process of automation, emergency stop protection is provided, as well as emergency treatment measures for various emergencies. After addressing the used convenience, focus on security.According to different customer processes, customers can set up in a simple operation interface and get the running status at any time.

Design Questions

Rotary kiln is not a standard product, so it needs to be designed according to the customer's process requirements.GWL will carry out detailed design according to the output requirements provided by the customer, as well as the specific gravity of the sintering material, and the use temperature, so as to ensure that every link conforms to the scientific basis.And according to the customer sintering process to make reasonable Suggestions, at the same time to consider the conditions of environmental protection, according to different requirements, we have different design schemes.

Product Usage

Rotary kiln can be used for municipal waste incineration (need to be equipped with exhaust gas purification furnace), powder sintering with large production requirements, particulate sintering with large production requirements.It can be used for the sintering processing of various raw materials, especially for batteries and the new energy industry.

Packing&Shipping

The normal package is the wooden box(Size: L*W*H). If export to European countries, the wooden box will be fumigated.If the container is too tight, we will use pe film for packing or pack it according to customers special request.

Shipment by sea, by air or by express as per customer's requirement.Our company has established a cooperative relationship with many logistics enterprises to guarantee the safe transportation of goods and the time limit.

Company Introduction

Luoyang Juxing Kiln Co., Ltd which is a manufacturing company that manufactures good & high-quality electric resistance laboratory furnaces and industrial kilns. The company provides the customized products and OEM service. The factory owns proficient skills and an updated machine. the company has passed the IOS quality management system. and some products have passed the EU CE certificate.

Our Services & Strength

Our product has widely used in ceramics, metallurgy, electronics, glass, luminescent materials, non-ferrous metals, chemical industry, machinery, refractories, new materials development, special materials, building materials, and other fields.And can be customized according to the customer's process requirements.

All kinds of electric furnaces have a high degree of automation and are at the leading level in China. They are sold to more than 20 provinces, municipalities, autonomous regions and special zones in China, national key colleges and universities, national key laboratories, Chinese Academy of Sciences, and High School Research Institute. Countries such as North America, Russia, the Philippines, and Japan. has a high reputation in the industry.

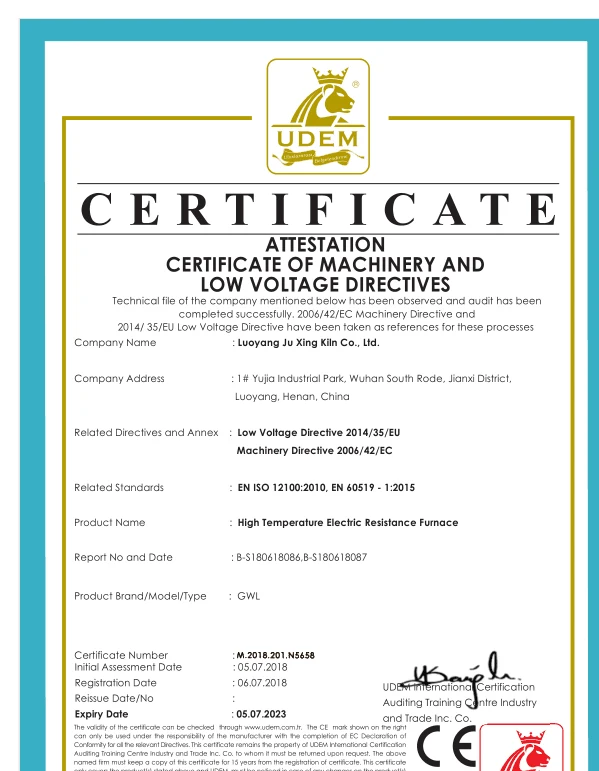

Certifications

Exhibition

Related Products

FAQ

Q: IF I NEED SPECIAL DESIGN ABOUT FURNACE CHAMBER DOES YOUR COMPANY CAN OFFER IT?

A: Don't worry about it, we have the excellent technical team, based on your requirement we can customize whatever you need.

Q:IF WE PURCHASE YOUR PRODUCT WOULD YOUR COMPANY GIVEN ANY TRAINING OR TECHNICAL SUPPORT?

A: LOL, that is a good question for us, just take relax, for sale is only the first step for us, we will give the basic training

about how to use our product through Technical manual and operation videos, and also Engineer is 24hours standby your call, as we promised we provide the best service for our client.

Q: HOW IS YOUR PRODUCT AFTER-SALE GUARANTEE?

A: We provide one-year service for our product (except the heating element), the heating element we provide three-month service.And also, the engineer available doing service overseas.

Q: YOUR PRODUCT WITH ANY ACCESSORIES?

A: Yes, the standard accessories include (Heating Elements, Specification Certificate, Heat Insulation Brick, Crucible Pliers,

High-Temperature Gloves).

Q: HOW TO CONTACT YOUR COMPANY?

A: Our Company address is: Yujia industrial zone, Wuhan south road, Jianxi District, Luoyang Henan, China.

A: Don't worry about it, we have the excellent technical team, based on your requirement we can customize whatever you need.

Q:IF WE PURCHASE YOUR PRODUCT WOULD YOUR COMPANY GIVEN ANY TRAINING OR TECHNICAL SUPPORT?

A: LOL, that is a good question for us, just take relax, for sale is only the first step for us, we will give the basic training

about how to use our product through Technical manual and operation videos, and also Engineer is 24hours standby your call, as we promised we provide the best service for our client.

Q: HOW IS YOUR PRODUCT AFTER-SALE GUARANTEE?

A: We provide one-year service for our product (except the heating element), the heating element we provide three-month service.And also, the engineer available doing service overseas.

Q: YOUR PRODUCT WITH ANY ACCESSORIES?

A: Yes, the standard accessories include (Heating Elements, Specification Certificate, Heat Insulation Brick, Crucible Pliers,

High-Temperature Gloves).

Q: HOW TO CONTACT YOUR COMPANY?

A: Our Company address is: Yujia industrial zone, Wuhan south road, Jianxi District, Luoyang Henan, China.

Похожие товары

Порошковый сплав средней частоты для спекания с электрическим сопротивлением, материал на основе Fe для коммуникационного оборудования

0,03 $ - 0,05 $

High purity Dead sintered magnesite 90% with high bulk density 3.28 with competitive price

Metals, Ceramics, Nanomaterials Rapid Powder Consolidation Spark Plasma Sintering System SPS

57 000,00 $ - 60 000,00 $

A1 цветной 98*10 ультрапрозрачный CADCAM system Стоматологический материал стоматологический Цирконий

Промышленные непрерывные порошковой металлургии оборудование MIM части спекания печи производитель

Multi-mix contour zirconia 98mm restoration material thickness 16mm color B1 Factory direct sales

Высокочистый спеченный вольфрамовый шар для продажи

Новые поступления

Новинки товаров от производителей по оптовым ценам

Кокосовая стружка мягкая и сладкая на вкус без глютена запеченная Ароматизированная упаковка для приготовления пищи кондитерских

Медицинский одноразовый стерильный катетер

Эффективные акустические панели эффективные звукоизоляционные материалы для качественной

65% полиэстер/35% хлопок саржа TC камуфляжная ткань 220gsm с водонепроницаемым принтом

1,48-1,61 $

Органическое жидкое мыло для мытья рук оптом

0,66-1,46 $

Высокое качество Sunpal 450W-600W 48V фотоэлектрические солнечные панели 500W 500Wp 600W заводская цена с белой задней простыней

0,28-0,32 $

2025 руиба новый продукт зажим для пуповины оптовая продажа медицинский стерильный одноразовый пластиковый

Оптовая продажа индивидуальные синие 3-слойные одноразовые маски для лица хирургические медицинские защитные взрослых

40-41,80 $