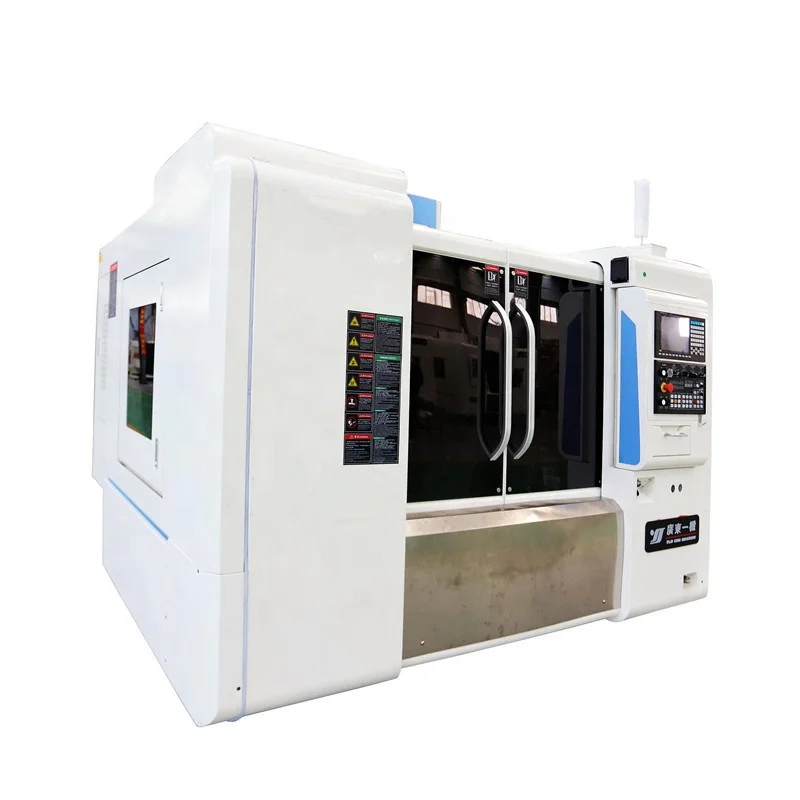

Низкая стоимость 3 оси ЧПУ vmc машина VMC460 китайский cnc обрабатывающий центр с для

- Категория: >>>

- Поставщик: Jinan Hankui International Trade Co. Ltd.

Сохранить в закладки 1600052454461:

Описание и отзывы

Характеристики

SPECIFICATIONS FOR 3 axis cnc machining center | ||||||

The Travel | X-axis travel | 460mm | ||||

Y-axis travel | 320mm | |||||

Z-axis travel | 460mm | |||||

Distance from Spindle center to table | 90-550mm | |||||

Distance from Spindle center to table | 395mm | |||||

Bench size | 800*300mm | |||||

Max. loading | 200kg | |||||

T-solt width | 14 | |||||

T-solt quantity | 3 | |||||

Spindle | Taper specifications | BT40 | ||||

Spindle speed (Optional) | 10000 RPM (optional) | |||||

Spindle motor | 3 K7.W | |||||

Rapid moving speed | X/Y -axis rapid moving speed | 10000mm/min | ||||

Z -axis rapid moving speed | 10000mm/min | |||||

The feed rate of cutting | 1-4000mm/min | |||||

Positioning accuracy | 0.01 | |||||

Repeat positioning accuracy | 0.007 | |||||

Max. tool Diameter | φ80/φ120mm | |||||

Max. tool length | 200mm | |||||

Max. tool weight | 6kg | |||||

It is of semi closed loop vertical machining center with X, Y, Z axis controlled by servo motor directly. The three axis are all the steel ball rolling linear guide rail which is large load capacity, wide span and high precision. XY axis is 35mm overloading and Z axis is 45mm overloading .Compact and reasonable structure and dimensions. Spindle is driven by servo motor through synchronous belt. It can finish clamping one-time of various dishes, plates, shell, cam, mold and other complex parts. It can complete the drilling, milling, boring, reaming, expansion, and other rigid tapping process . so it is suitable for many varieties, medium and small batch production. It can finish the processing of complex, high precision parts . It can be matched the four rotary shaft , in order to meet the requirements of special parts.

A: Yes, we are happy to give advice and we also have skilled technicians available, We need your machines running in order to keep

your business running.

Q: Once we've bought a machine from you, are you able to supply us with material?

A: We can assist you in finding the appropriate materials to suit your machine

Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.OEM is acceptable

Q: Do you have a warranty on your machines?

A: One year warranty excluding electrical components.

Q: What sales terms do you have?

A:T/T, L/C,West Union.

Q: Do you have instruction manuals?

A: We provide you with instruction manuals, electricity layouts, civil requirements, and machine drawings or Video Support,

Q: Once machine arrives at our factory what happens then?

A: We will send you a technician or engineer that will commission and install your machine, with training for your staff if

required at a separate fee.

Q: What do I need to offload my machine from the container?

A: You are not responsible for the offloading of your machinery, and it is recommended that you use a reputable rigging company.

Q: What kind of controls/Parts do you use on your machines?

A: AMS, OMRON, Schneider, Siemens, and ASK,ABBA,OPTIMA(ITALIA),HSD

Q: What is your delivery time?

A: Depending on the type of machine, duration of 10 days to 45 days from date of order.

Q: Do we receive any updates while machine is in the manufacturing process?

A: Yes.Regular updates on progress will be sent to you.

Похожие товары

Передняя вилка для мотоцикла TITAN 2000 KS от китайского производителя

Двойное Фланелевое теплое одеяло NFL Теннесси Титаны по хорошей цене

Дешевая горячая Распродажа модный длинный волнистый вьющийся парик светлый натуральный полный для леди девушки красоты

Чехол на руль для Nissan патруль Армада NV грузовой NV пассажир (США) Титан Infiniti QX56 оптовая цена для вас

Полуавтоматическая блокировочная машина для производства блоков почвы и цемента по самой низкой цене

Высокоточный недорогой полностью автоматический вертикальный обрабатывающий центр с ЧПУ

Экономичный диоксид титана анатаз B101 по низкой цене

Новые поступления

Новинки товаров от производителей по оптовым ценам