Высокоточная настольная машина с полуавтоматическим шнековым винтовым наполнителем 1 г до кг для бутылок банок мешков сумок порошков

- Категория: >>>

- Поставщик: Guangzhou Trust-Long Packaging Machinery Co. Ltd.

Сохранить в закладки 1600056249066:

Описание и отзывы

Характеристики

Big hopper table top auger filling machine powder 1g to 1kg

Specifications:

Equipment control

| PLC operation panel, foot switch

|

Tank volume

| 20L (or can be customized bigger)

|

Filling volume

| 0.5-1000g ( or more, change augers) |

Filling accuracy | plus or minus 0-3% |

Filling speed | 10-30 times / minute |

Power source | 110V/220V,single phrase |

Machine power | 1.85KW

|

Weight | 120KG |

Size of machine | 550 × 550 × 1080mm |

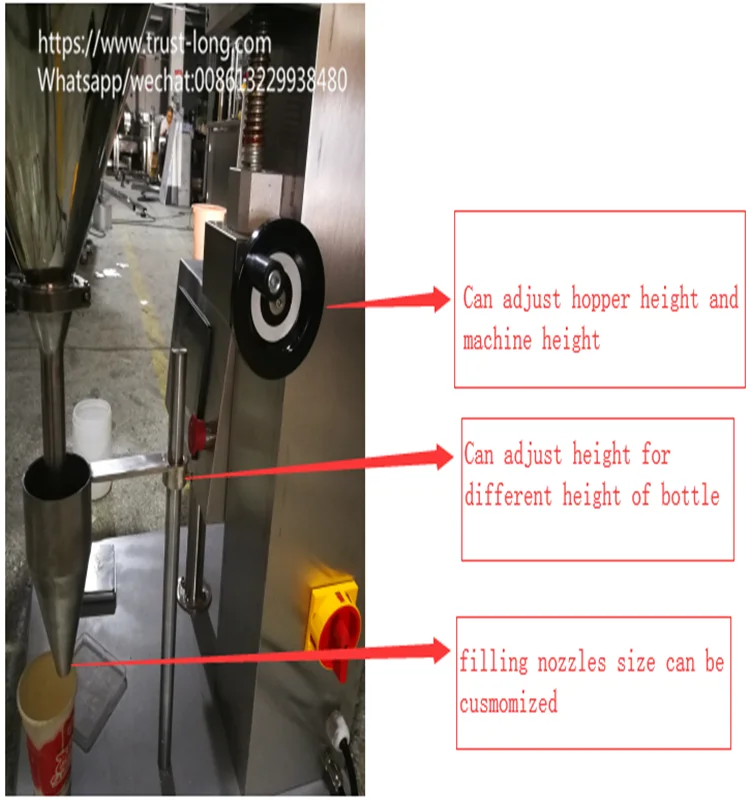

Product details:

Advantages :

1,Adopt servo motor motor which can brings more high precision of filling ;

2. 20L hopper , no need powder feeder to work with it is Ok too and no need put powder by hand often;

3. filling ranges is larger, can be from 10 g to 500g or more , but need to change screws;

4. The equipment has stable performance, convenient operation and maintenance, low failure and high efficiency;

5, unlimited packaging containers (bags, cans, bottles cups can be);

6The mixing adopts Taiwan-made maintenance-free geared motor: low noise, long life, maintenance-free for life.

7.Designed as a weighted feedback specific gravity tracking type, which overcomes the shortcomings of weight changes caused by changes in material specific gravity.

Small table top auger powder filling machine description:

The semi-automatic filling and packaging machine can automatically complete the tasks of metering, filling and weighing. Because it is designed in accordance with national GMP standards.

Filling products application:

it is suitable for packaging those powdery and granular materials that are easy to flow or have poor fluidity, such as milk powder, feed, rice flour, sugar, coffee, monosodium glutamate, solid beverages, glucose, rice flour, powder and granular additives. , Dyes, etc. This powder filling machine is integrated with machine, electricity, light, and instrument.

Functions Features:

Quantitative, automatic filling, automatic adjustment of measurement errors and other functions; fast speed: using spiral cutting, light control technology; high accuracy: using servo motor and electronic weighing technology;

Different models , just want to make best for you !

Other models for reference:

⇒ Desktop powder filler ⇒ Simple automatic powder filling line

Model:TLP-300 Model:TLP-5000

Feature: 8L hopper, can fill max 500g powder Feature: can fill max 5000g , automatic filling

Packaging samples for refrence;

1.How long can ship the goods?

-often it costs about 15 days after deposit

2. terms of payment

-often 30% deposit, and rest payment is paid before delivery .

3.Do you have QC?

- Yes, each machine is tested by technician before sending out and later packed with free spare parts .

4. Any spare parts?

- If it's necessary, there are free spare parts sent together with machine.

5. Warranty: One year after shipment. If because of machine quality problem, seller pays the service and free repaired during one year. If cause by improper operation, seller not responsible for it. If buyer need spare parts after that, seller can supply them and sent by express if needed.

6. Free Training:Train buyer's technician in seller's factory for free. But buy's technician need to pay for their living,eating and so on by their own.

9. Engineers service overseas:Support to send seller's technician to buyer's factory to install the machine and do the training for buyer's technicians.The buyer need to pay for all of travel charges for seller's technician, including visa fee, air tickets, the local accommodation, food, local traffic charges and so on. Also the buyer needs to pay for each of seller's technicians salary.

Похожие товары

1-2 мм бусины из пенополистирола для заполнения бобов

Jajer MY3 HH53P 5A 250VAC миниатюрное силовое реле электрические 11 pin-код реле

Реле общего назначения, электрическое реле переменного тока MY3 220 В

Плоский ролик ручной штамповочный станок для бумаги, пластикового листа

Высококачественный шоколад для детей

Для процессора Intel Core i5-3450 CPU 3,10 ГГц 6 м Quad Core Socket 1155 настольный процессор

1r0 1r2 1r4 1r5 1r8 6r8 smd силовой индуктор

Новые поступления

Новинки товаров от производителей по оптовым ценам