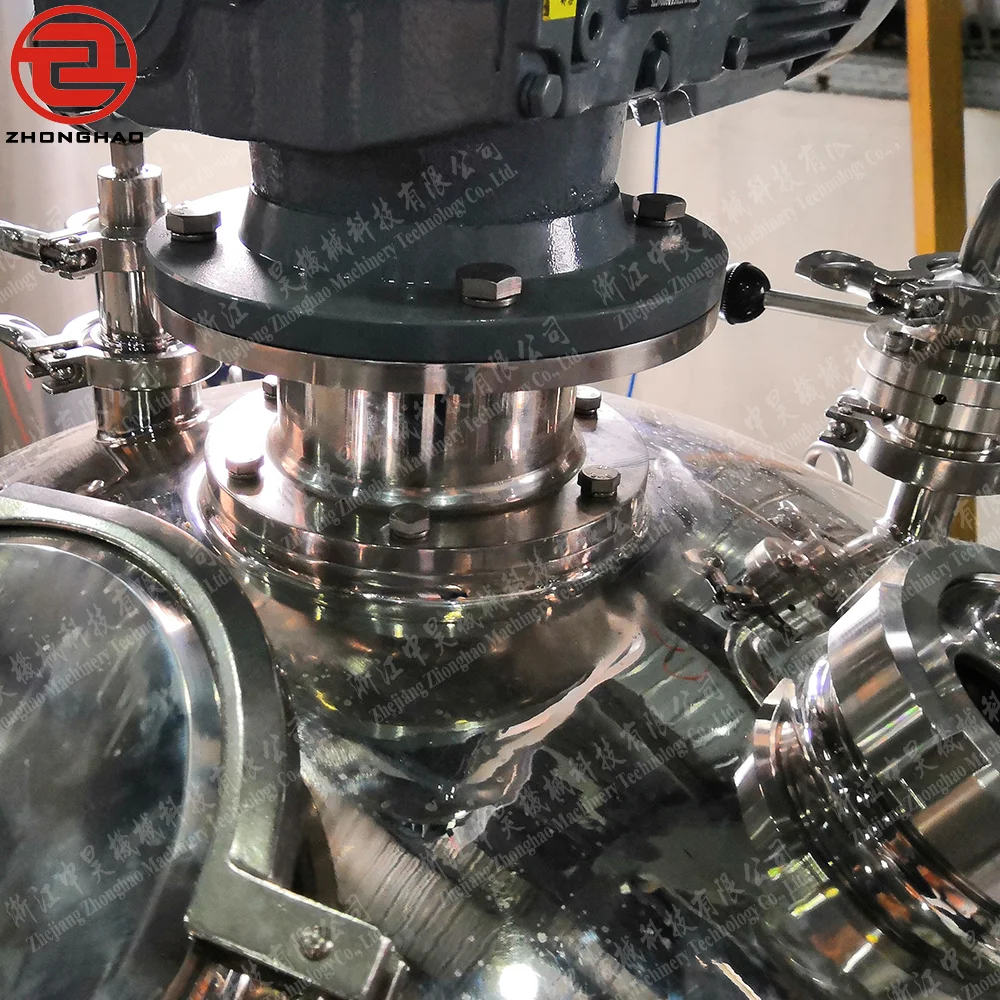

Пищевой санитарный химический реактор из нержавеющей стали оборудование с вакуумным насосом эмульгированный однородный смеситель для сиропа

- Категория: >>>

- Поставщик: Zhejiang Zhonghao Machinery Technology Co. Ltd

Сохранить в закладки 1600069789950:

Описание и отзывы

Характеристики

Food grade Sanitary Stainless steel chemical reactor equipment with vaccum pump emulsified homogeneous mixer tank for syrup![]()

The reaction kettle is usually called a reaction pot or a reaction tank, the heating principle is to put the material into the tank , the steam heat into the kettle, so that the heat of the material in the reactor, steam heating reaction kettle, steam as heat source heat exchange. There are three kinds of steam heat exchange mode: jacket heat, coil heat, half coil heat exchanger. At present, the most popular advanced reaction kettle heat transfer technology is the technology of semi disc steam heat transfer, which overcomes the shortcomings of the traditional heat exchange technology, such as low thermal efficiency, large diameter of the kettle body, and reduce the thickness of the reaction kettle, save manufacturing costs.This equipment is used in the process of hydrolysis, neutralization, crystallization,distillation and evaporation in pharmaceutical, chemical, food, light and other industries.

Products Name | Food grade Sanitary Stainless steel chemical reactor equipment with vaccum pump emulsified homogeneous mixer tank for syrup |

Material | SS304/SS316L |

| Jacket: full jacket ,dimple jacket , coil tube |

| Insulation layer: PU / rockwool |

| as to the thickness, we can make it according to your requirement. |

Description: | Designed according to 3A standard, widely used for transfer viscous media in the food-processing, cosemtics and pharmaceutical industries |

Heating mothed: | By electricity (oils or water), by steam , circulation heating (hot water or oil) |

Configuration: | 1.manhole |

| 2.CIP spraying ball |

| 3.adjusting feet |

| 4.sight glass |

| 5.temperature gauge |

| 6.pressure gauge / vacuum gauge |

| 7.breather |

Capacity: | 50L-10000L |

Mixer Type: | High shear Homogenizer or Agitator ( anchor , frame , stirrer with side scraper , blade ,impeller ) |

Mechanical seal: | SIC/SiC/EPDM(Standard) |

Agitator power: | 0.55kw -75KW |

Sealing option: | Sanitary single mechanical seal/Double mechanical seal with cooling system |

Voltage: | 220V -480V |

Motor: | ABB, SIEMENS , SEW , Domestic |

Surface treatment: | Inner polished and outside polished |

Availably connection: | Clamp, Thread Butt weld, Flange |

Availably standard: | DIN, SMS, 3A, RJT, ISO/IDF |

Operated: | Electic |

Application scope: | Dairy, food, beverage, pharmacy, cosmetic, etc |

Packaging Details: | Export Plywood case |

Delivery details: | Usually within 25-30 days after receiving T/T down payment |

Zhengjiang zhonghao machinery technology co.ltd. Was found in 1999,before was Tianhe machinery.

Is a new comprehensive enterprise with collection of design,development,,manufacturing engineering installation and after-sales service.Our main staineless steel products includ the Extraction tank,concentrator,reaction kettle,Mixing and dispersing equipment,Emulsification machine,Sanitary pump,Colloid mill,ect.Zhonghao adhere to the people-oriented,has served thousands of enterprises.We rely on our own strength, high quality and quality service to win confidence and praise of the global chemical,pharmaceutical,food,environmental manufaturers.

Похожие товары

Новый дизайн, дозатор воды POU RO UF по заводской цене

2020 HDPE одноразовые чехлы для сидений, торговая компания, использованная автомобиль, предотвращает бактерии

Непрозрачная умная тонировка pdlc для конфиденциальности, переключаемая оконная стеклянная пленка

Мини-холодильник на батарейках 25 литров

Инфракрасное сквозное отверстие 3 мм/5 мм ir led dip 1400 нм

Тормозной суппорт авто запчасти автомобиля автозапчасти тормозная система тормозной суппорт для Honda Civic Coupe Elysion Prestige

Автозапчасти безшумной тормозной башмак

Новые поступления

Новинки товаров от производителей по оптовым ценам