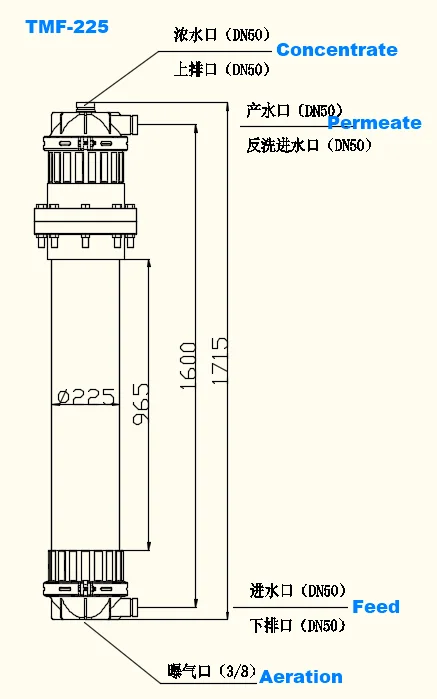

Лидер продаж трубчатая микрофильтрационная мембрана для промышленной обработки воды размер TMF225 12A 1500 л/ч

- Категория: >>>

- Поставщик: Guangdong Rich Kirin Environmental Technology Co. Ltd.

Сохранить в закладки 1600072011750:

Описание и отзывы

Характеристики

Top hotsale tubular column size TMF225-12A 1500L/H composite tube microfiltration membrane for industrial water treatment

Product Description

1. Membrane tube high strength, permanent non-facture

2. The membrane assembly is resistant to high pressure and allows 0.3Mpa of gas-liquid scrubbing

3. The membrane assembly has excellent damage resistance and can withstand the scrubbing of various hard suspended substances in water

4. Membrane components cleaning and backwashing effect more thorough

5. Membrane components have good adaptability

6. Good chemical stability

Performance of membrane module | TMF225-12A datasheet | |

| Dimension | 1715L*Φ225mm | |

| Pack size | 180L*35W*36D/mm | |

| Gross weight | 43KGS/CTN/PC | |

| Membrane material | HDPE+PVDF | |

| Hollow fiber ID/OD | 6mm/12mm | |

| Pore size | 0.1um | |

| Design flow rate | 800-1500L/H | |

| Membrane area | 8.2m2 | |

| Connector size | DN50(Φ63) | |

| Housing material | UPVC | |

| Sealing material | Epoxy resin | |

Membrane module parameters | Operation mode | External pressure |

| Operation pressure | 0.05-0.3Mpa | |

| Max.feed pressure | 0.4Mpa | |

| PH | 2-12 | |

| Operation temperature | 1-40℃ | |

| Influent turbidity | ≤200NTU | |

| Permeate turbidity | <0.1NTU | |

| Particulate(>0.2um) | ≥99.99% removal | |

Backwash design | Backwash frequency | 15-60min/time |

| Backwash method | Gas-liquid mixed scrubbing | |

| Water backwash pressure | ≤0.3Mpa | |

| Water backwash flow | 3 times of water production | |

| Air scouring flow rate | 8~12 Nm³/H | |

| Gas scrubbing pressure | 0.1-0.3Mpa | |

Chemical wash design | Frequency of chemical cleaning | 1-4 months/time |

| Pickling agent | Citric acid, oxalic acid or hydrochloric acid(with PH=2 solution) | |

| Alkali wash agent | NaOH+NaCIO (with PH=12 solution) | |

Company Profile

Guangdong Richkirin Environmental Technology Co., Ltd is an international environmental protection technology-basedenterprise which has specialized in membrane products & full water treatment equipments research and development,manufacturing, sales and service for 15years.

With advanced core membrane manufacturing technology and 15 years of practical experiences, we successfully modify alltraditional filtration materials to produce whole series high-quality water treatment products. Our products include: Tubular microfiltration membranes,ultrafiltration membrane, MBR membrane modules and various environmental protection equipment systems such as UF , RO, MBR wastewater treatment plants and other customized water treatment equipments. They are widely used in industries such as tap water upgrading, steel mills, power plants, water reuse, surface treatment, electronics, photovoltaics, cutting, grinding, garbage permeate and wastewater treatment.

By introducing the international advanced standards ISO9001:2015 Richkirin has created a high-level product quality managementsystem from raw material to finished products. All products are 100% test and guarrantee perfect aftersale service of long shelflife.With such advantages of stable performance, large yield, small attenuation and long service life, Richkirin's membrane products are well known by more and more buyers of water treatment industry in domestic and abroad. Insisting on continuous innovation and keeping pace with advanced technology & standards, Richkirin dedicates to providing customers with high-quality products and professional technical services, finally strive to build a modern enterprise in the water treatment industry.

Certifications

Packing & Delivery

FAQ

Q1: Could you offer on-site installation service?

Yes, we can installate the membrane for you if you don't get sence of the operation manual( technical operation video & online support)

Q2: Why did I choose your product?

We have advanced technology, unique design, excellent performance, lower maintenance cost and perfect after-sales service.

Q3: How about your lead time?

The production lead time time is about 10-20days after received your deposit.

Q4: Can I customize my logo on the product?

Yes, we can offer the custom service such as the color, design, and logo based on your quantity request.

Q5: What is your MOQ?

Normally our MOQ is 10pcs, current size is 1pcs. Please do not worry about the small quantity problem. We could do one-stop service for you.

Q6: How can I get an offer?

You can send your drawing with technology requirements such as influent & effluent parameters and your quantity of membrane. It is much better if you could offer the usage information about your product. We shall confirm the most suitable material and quote the best cost to you in 24 hours.

Related Products

Похожие товары

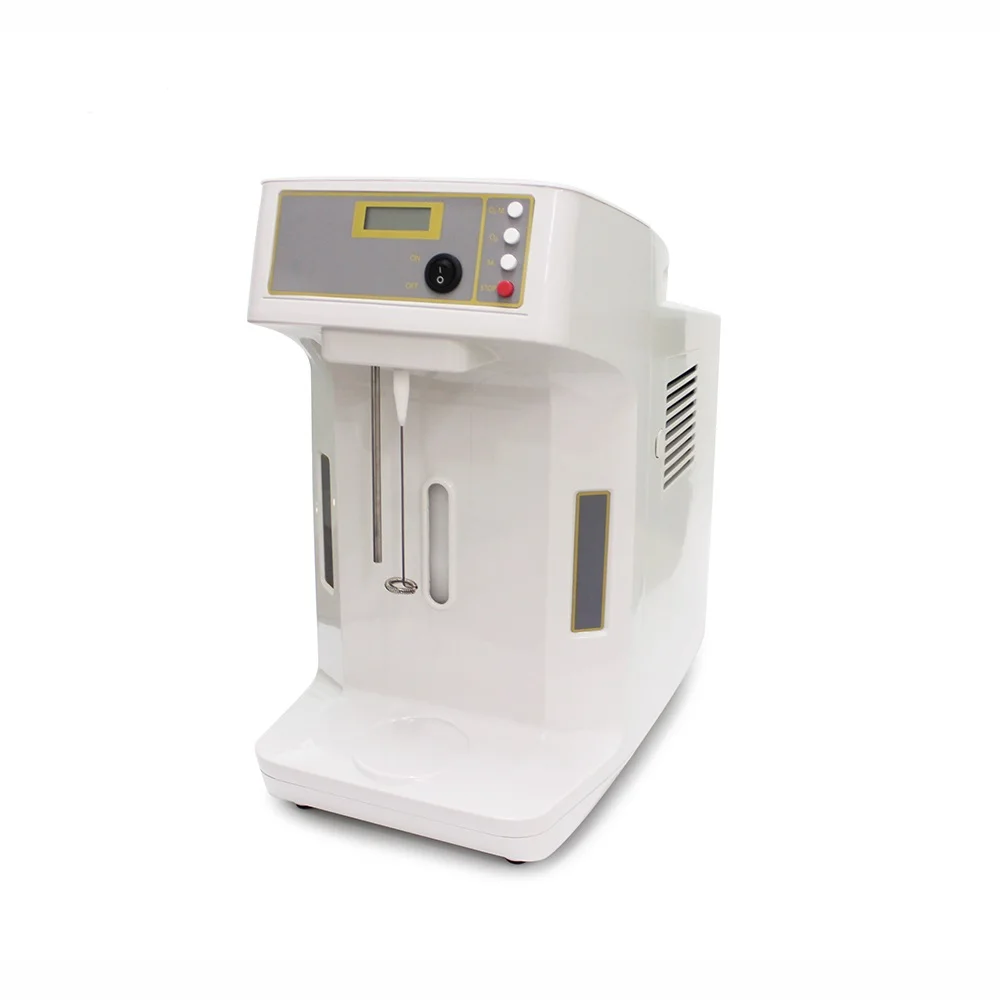

Главная машина для кислородных коктейлей делая машину JAY-1A

Двухдверная гуманная живая крыса ловит грызунов животных металлическая крыса ловушка для мыши

Горячая Распродажа, пластиковые бутылки 100 мл, цилиндр для упаковки лекарств, пластиковый контейнер для таблеток

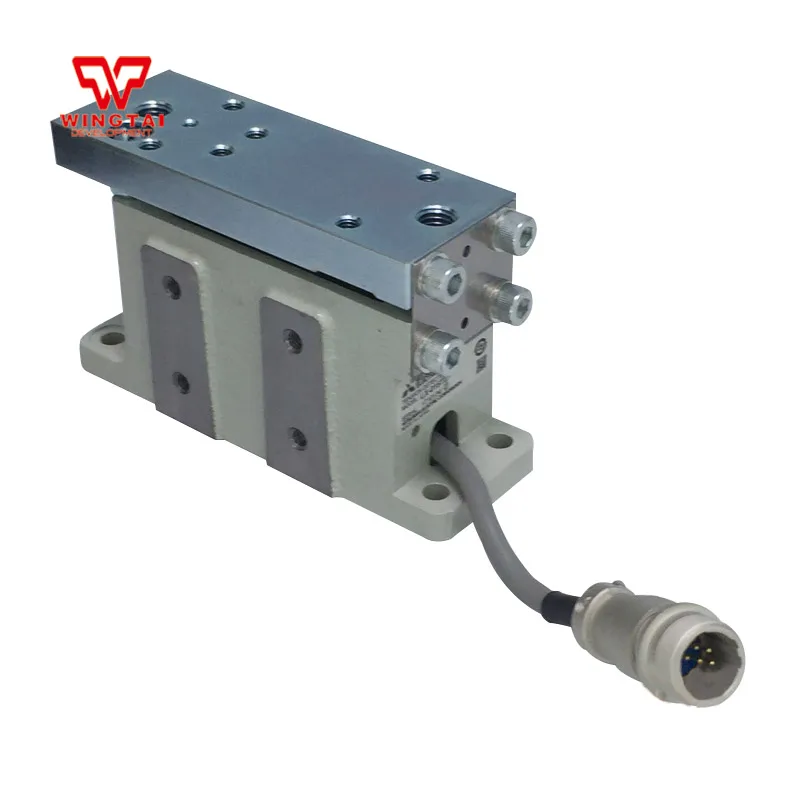

Japan mitsubishi LX-050TD Micro Deflection Tension Detector, LX-TD Series

Оригинальное качество 1430 мА/ч, bl-5j Аккумулятор для nokia 5800 5230

Тормозной барабан для оси прицепа от профессионального производителя

E39 E40 Meanwell 100w 120w 150w 200w 240w 300w Shoebox, уличный прожектор, светодиодные комплекты для модернизации

Новые поступления

Новинки товаров от производителей по оптовым ценам