Оборудование для производства полиэтиленовых водопроводных труб машина

- Категория: >>>

- Поставщик: Jiangsu Xinrongplas Machinery Co. Ltd.

Сохранить в закладки 1600075959623:

Описание и отзывы

Характеристики

HDPE PPR Water / gas pipe making machine

Composite pp pipe extrusion line

HDPE Pipe Plant offered comprise complete range of extruder based HDPE pipe plants that come with optimum combination of technology and performance. Also coming fabricated in superior grade steel finish for long lasting durability, these can be provided with different working specifications including minimum Pipe OD (mm) and maximum Pipe OD (mm). Featuring high plasticized capacity from 550 kg/hr to 600 kg/hr

Salient Features of High Speed HDPE Pipe Plant

a: It is designed for an easy operability and performance optimization.

b:Screw & Barrel, PLC control system and Spiral Type Die Head and other parts of the High Speed HDPE pipe plant are designed in manner to bring optimum result and c:ensure better productivity results.

d: Made to ensure durability and longer life

e: Energy efficient ensuring lower power consumption

f:Corrosion resistance

Production Range for HDPE Pipe Extrusion Line:

What is HDPE pipe extrusion machine consist of?

Single screw extruder

As we have mentioned it is the main parts for HDPE pipe extruding machine, for different sizes pipe, we need different size extruder, you can ask the manufacturer which type of single screw extrusion machine is suitable for you.

Screw And Barrel

The screw adopt barrier type mixing zone.

The barrel feeding zone is groove feed bush and made of hard alloy.

It is result higher output rates,homogeneous plasticizing and material slippage

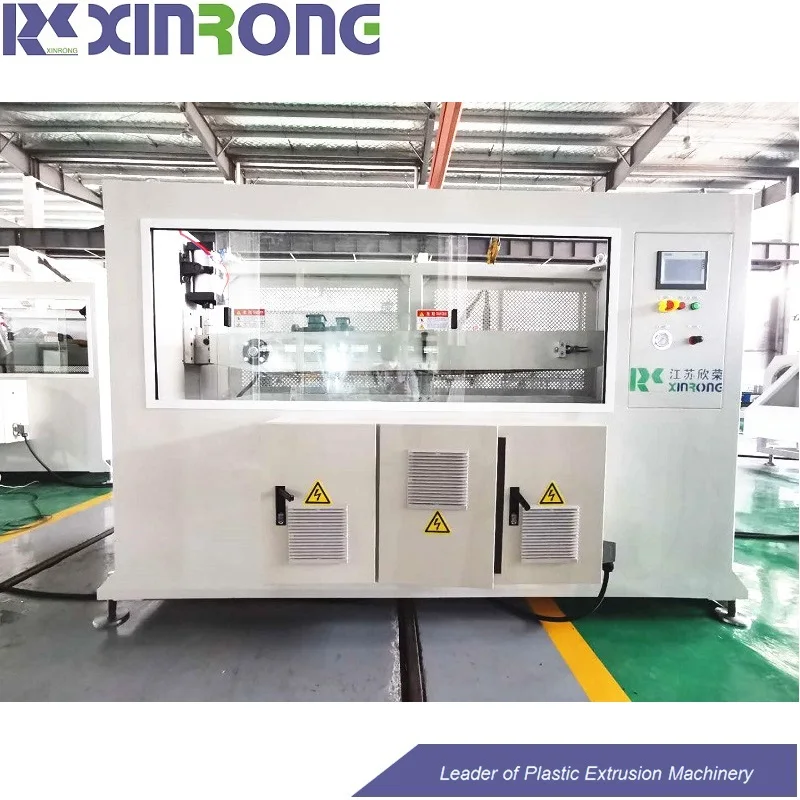

PLC CONTROL SYSTEM

There is an option for the whole line with PLC control system and large liquid crystal screen which makes the operation very convenient.

CO-extruder SJ30/25

For color mark line

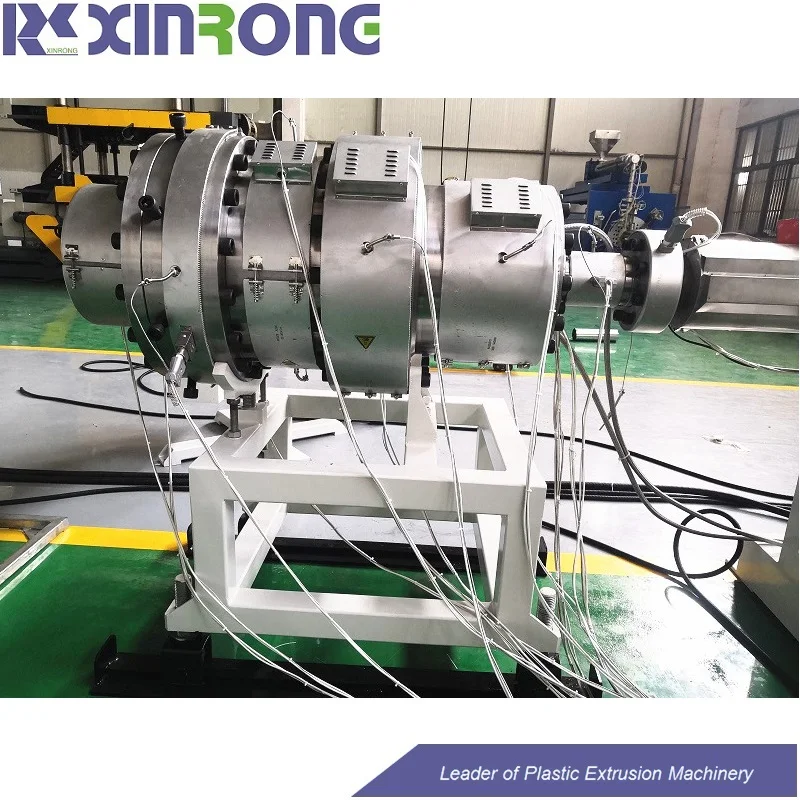

Plastic pipe extrusion dies

It is made by 40CR, the die head is heated by the heater inside of the mold, we use the temperature sensor to check its temperature, and the mold can be discharged by the screw when we need to clean the mold.

SPIRAL TYPE DIE HEAD

Spiral type die head ensures stable wall thickness of PE pipe even at higher output.

It can produce pipe upto630mm.

Low pressure diagonal channel with spiral mixing part ensures extrusion at low temperature and homogeneous plasticization.

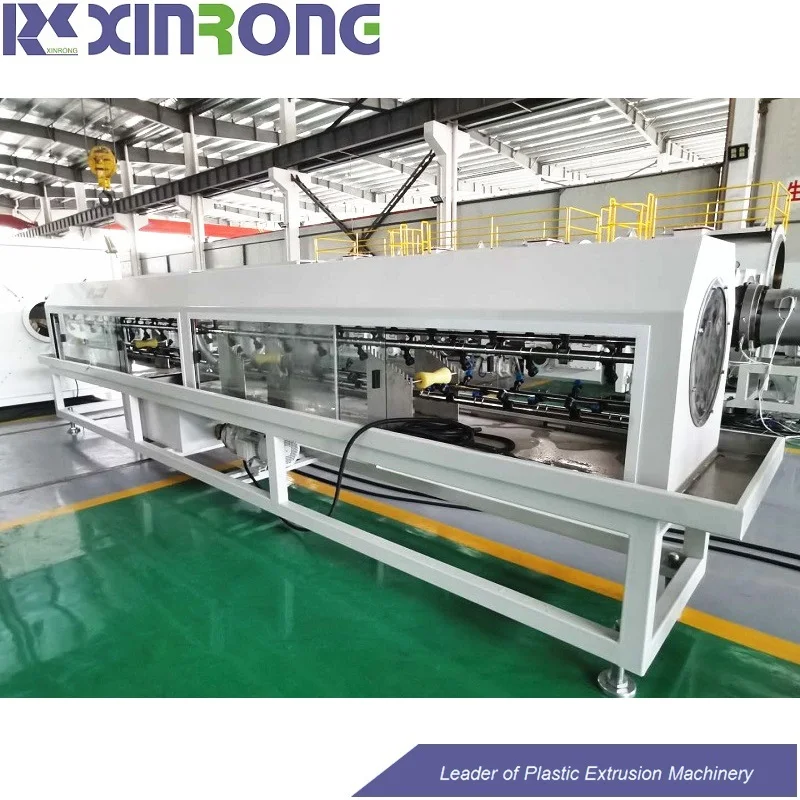

Vacuum tank

We have six meters and 9 meters long, there are two compartments in the vacuum tank.

Each compartment is installed one vacuum pump and water pump, the size of water and the vacuum pump is determined by the size of pipe and tank.

Vacuum Tank

Special design vacuum sizing can ensure the stability of diameter and roundness even when producing the pipe with higher wall thickness.

The water spray unit produces high speed spray vortex to achieve fine and even cooling effect.

Haul off machine

Designed for the toughest pulling jobs. These haul-offs are engineered for hauling heavier wall rigid pipe & profile. Options include a pneumatic floating upper belt to handle lumps & bumps at start-up.The puller belts are driven directly by twin AC servo motors through planetary gearboxes. Two AC servo drives are used; one for each motor. These are perfectly synchronised for optimum belt speed control.

Features:

Optimum performance

Durable

Corrosion resistance

Low power consumption

Easy operation

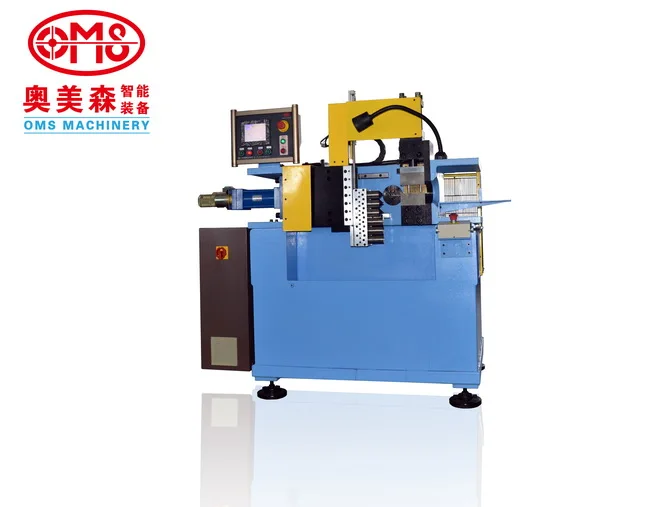

Cutter

pneumatic-powered Universal Pipe Cutters (UPC) for PE are available to cut 8” - 48” nominal diameter (200-1300 actual O.D. mm) PE pipe. We use the SIEMENS PLC and touch screen to control the chip free cutter, it can make the cutting machine working stable and with less noise.

Features:

Corrosion resistance

Easy operation

Durable

Low power consumption

Efficient performance

DOUBLE/SINGLE STATION COILER

Double station coiler can be provided for diameter up to 63mm.

Single station coiler can be provided for diameter up to 110mm.

What is the usage of pe pipes?

HDPE pipe is a type of flexible plastic pipe used for fluid and gas transfer and is often used to replace ageing concrete or steel mains pipelines. Made from the thermoplastic HDPE (high-density polyethylene), its high level of impermeability and strong molecular bond make it suitable for high pressure pipelines. HDPE pipe is used across the globe for applications such as water mains, gas mains,sewer mains, slurry transfer lines, rural irrigation, fire system supply lines, electrical and communications conduit, and stormwater and drainage pipes.

Our company introduction

Похожие товары

Автоматическая машина для изготовления заборных бетонных труб

Оборудование для прессования металлических труб круглая металлическая труба пресс холодного квадратная машина

Автоматизированный сварочный аппарат для производства бесшовных и сварных труб

Автоматическая Концевая формовочная машина с режимом колебания

Automatic high precision Slitting Line for HR Steel sheet in Hebei China

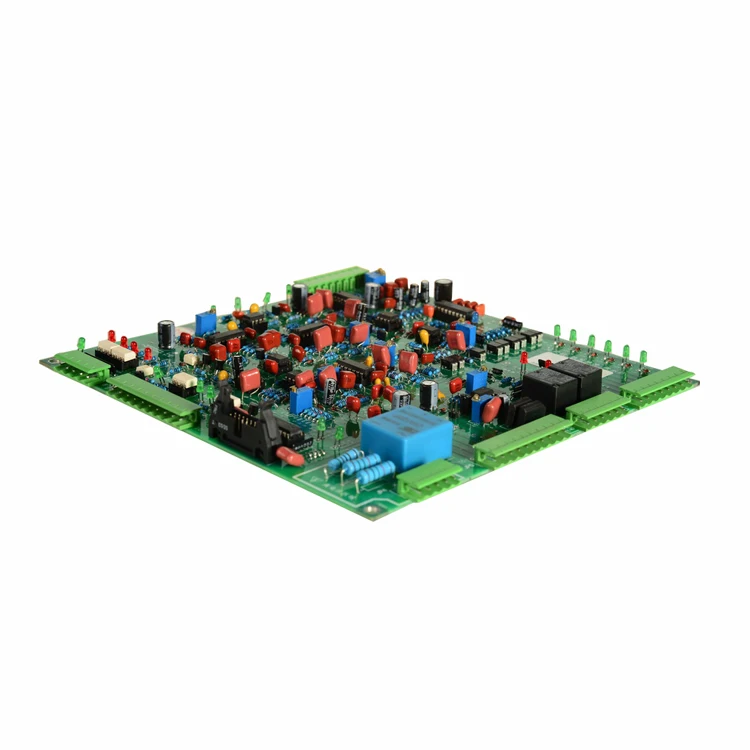

Приводная плата выпрямительная печатная

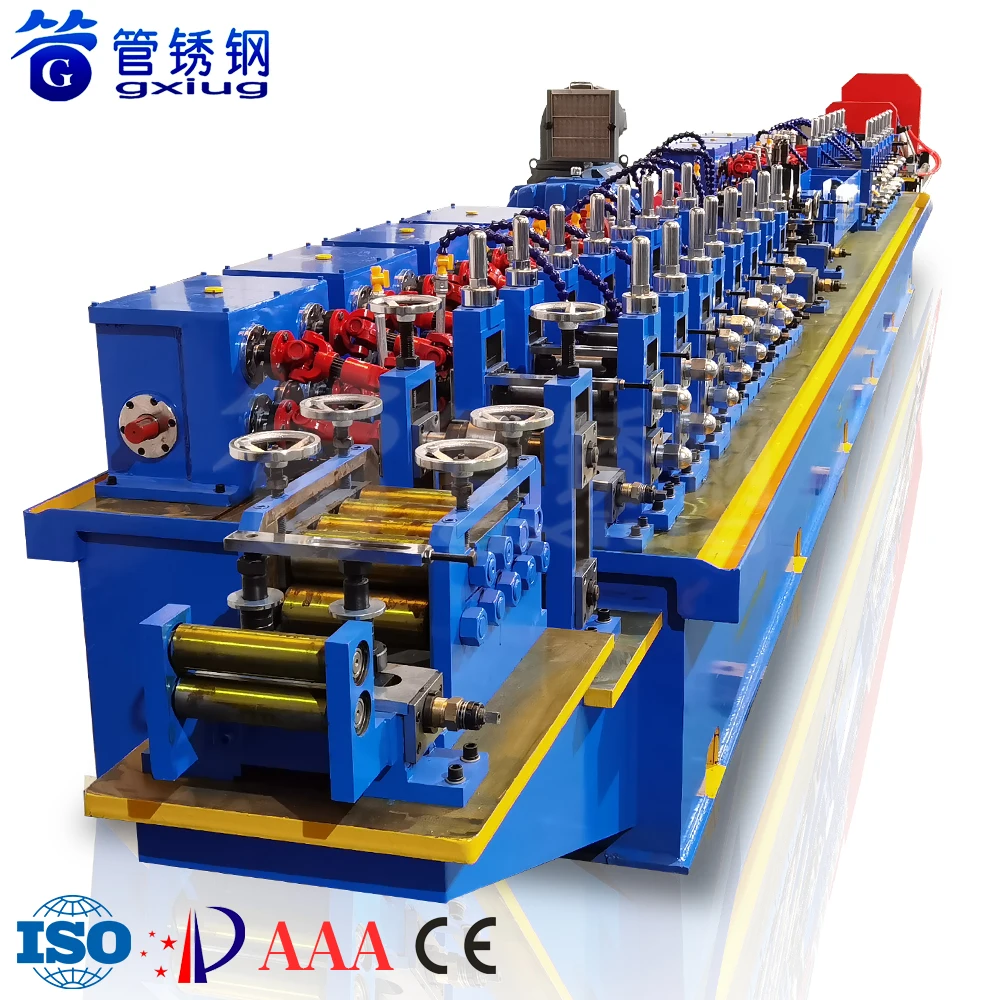

GXG технология высокочастотная сварочная труба линия продуктов поставщик механическая трубка цена от производителя

Новые поступления

Новинки товаров от производителей по оптовым ценам