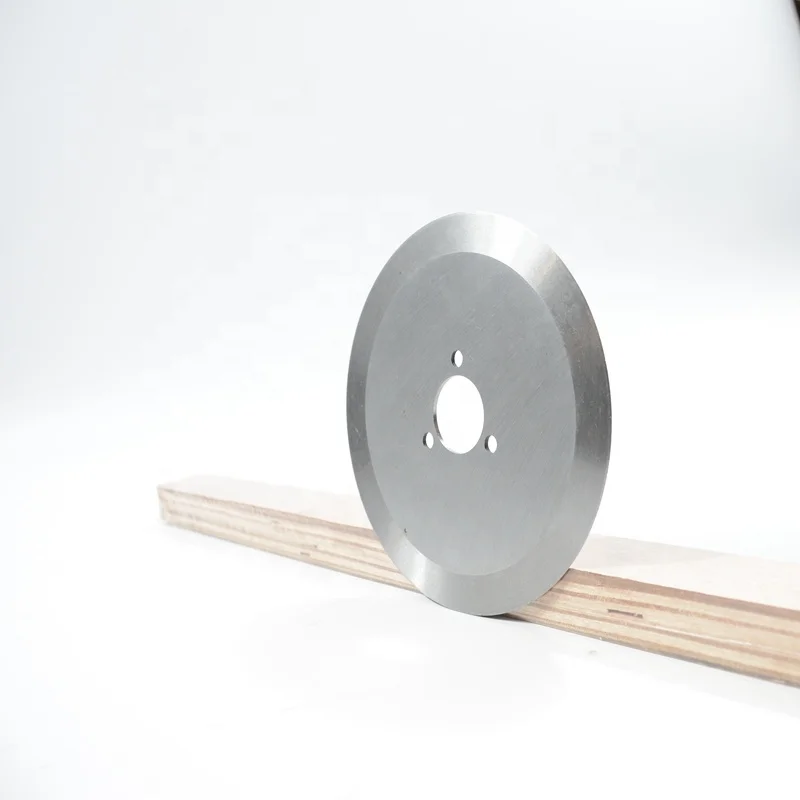

Круглый нож для продольной резки

- Категория: Industrial Blades & Knives >>>

- Поставщик: Goodklife Machinery Technology Co. Ltd. Maanshan

Сохранить в закладки 1600085689389:

Описание и отзывы

Характеристики

Product Description

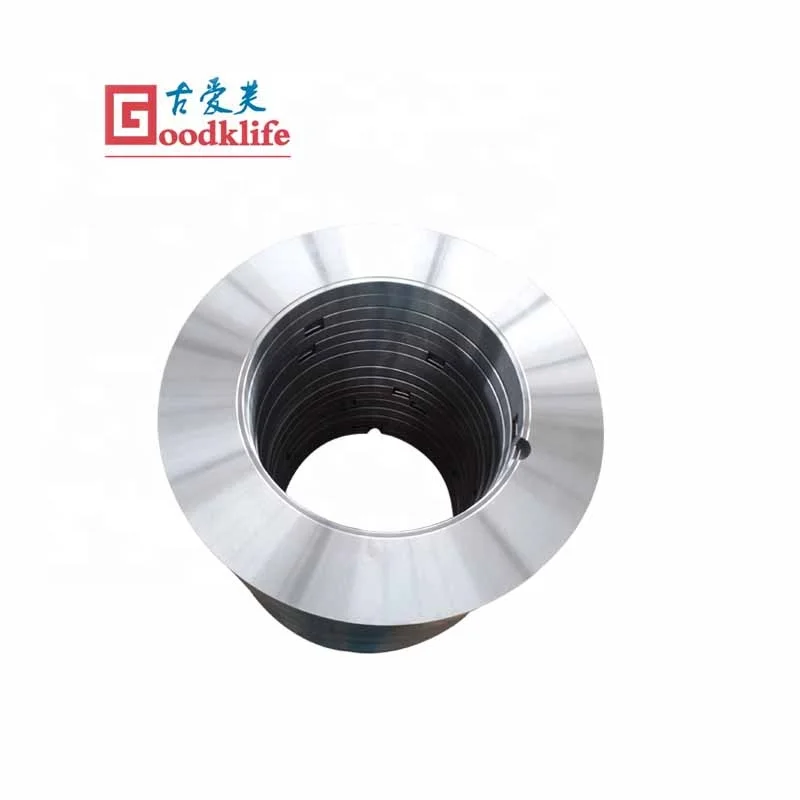

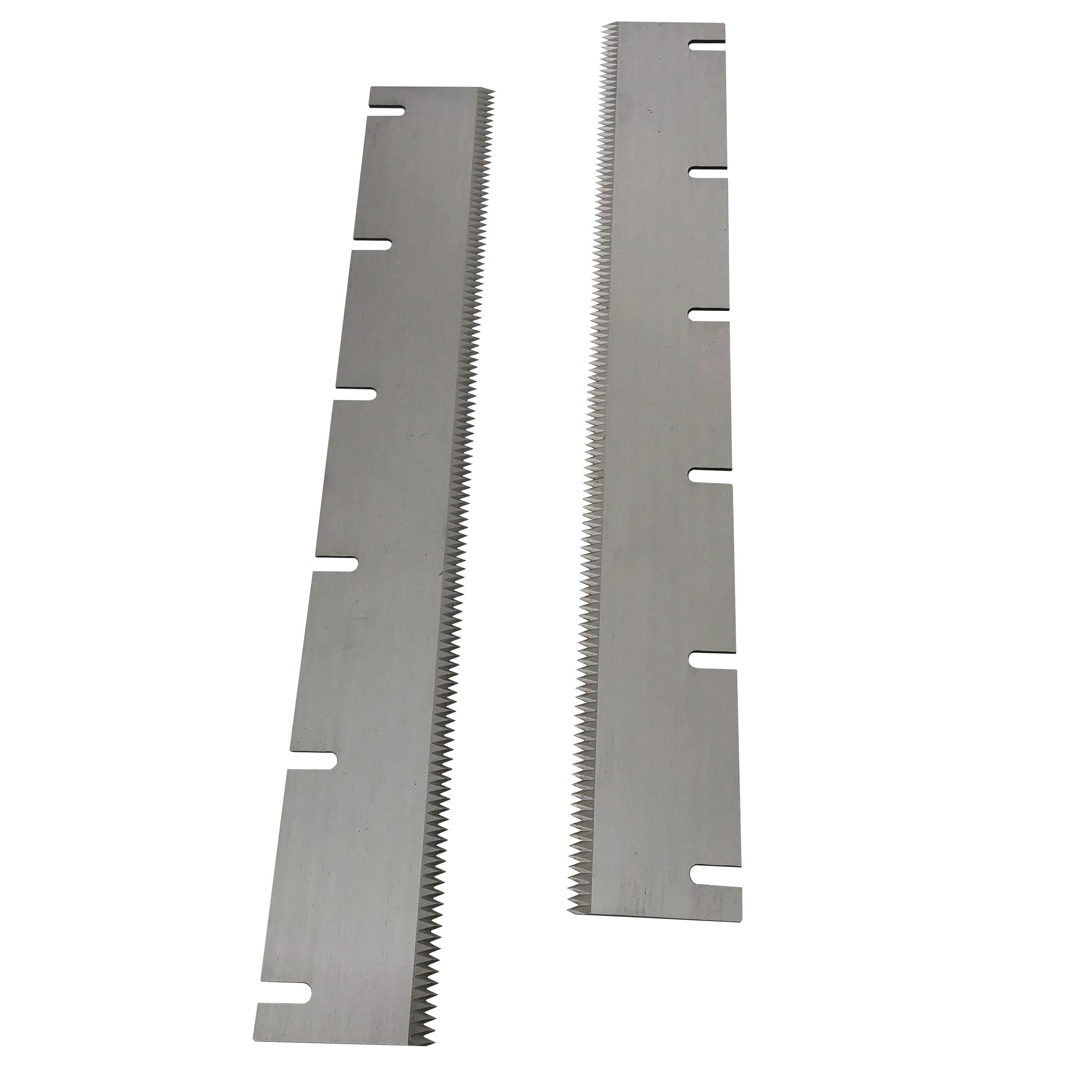

We manufacture slitting knives up to 1500 mm ( 59.06 inches ) in diameter for slitting and side trimming lines.

Materials | Alloy, Heat-resisting high alloy steel , D2 ,H13 and etc |

OEM & ODM | Provided |

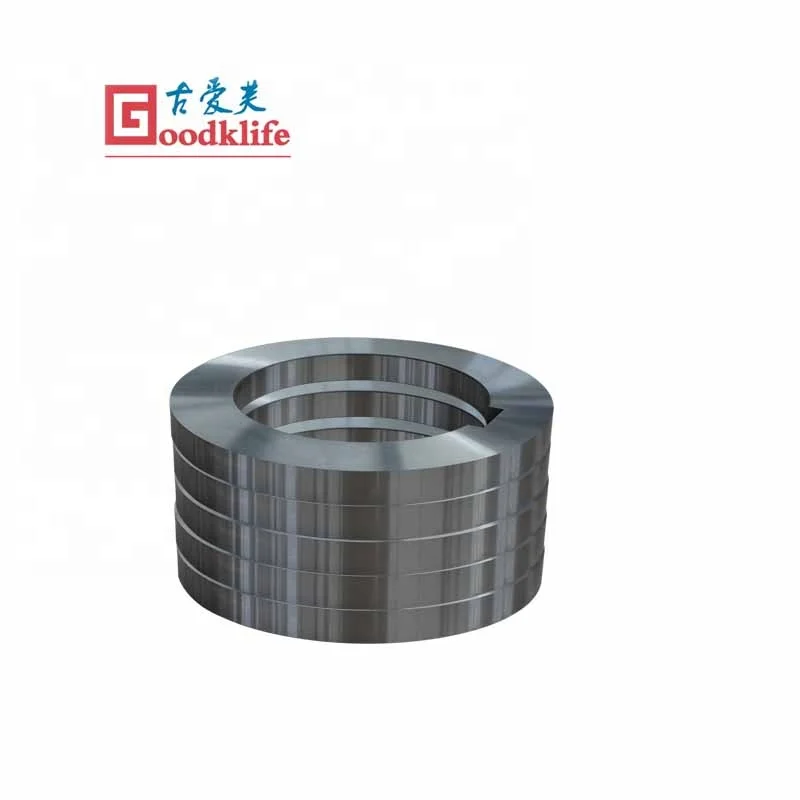

Merits | High toughness,High wear resistance |

Size | Custom |

Surface Finish | Ra0.4 or less |

Package | Plywood case |

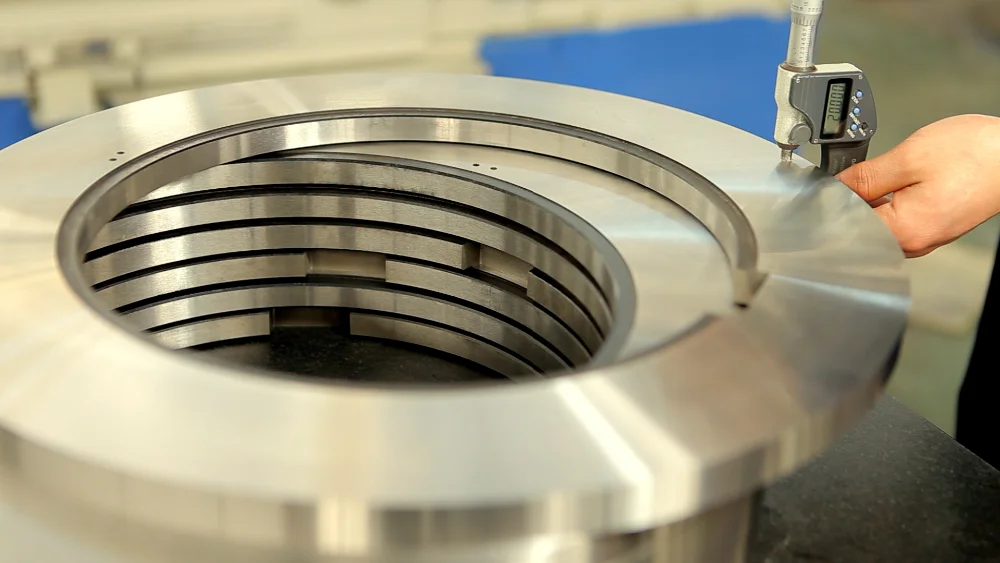

Parallelism | 0.002mm |

Thickness tolerance | ±0.002mm |

Production Progress

Manufacturing Technique

We have our own factory and professional team, customized to your needs, we can provide the best service.

Steel-choosing→Blanking →Forging Steel →Rough Processing →Heat treatment →Finishing→Testing

Goodklife company can meet special requirements for materials. In order to guarantee the qualit, the company imported the spectrometer from Germany and is equipped with various testers, such as tensile tester, impact testing machine, metallography analyzer and so on.

Electro slag remelting

The largest ingot can reach 3 tons in Goodklife company. The ingot obtained by this remelting/refining process is very homogeneous and free of internal defects. The segregation of the ingot (called macro-segregations ) are substantially eliminated and the segregations of crystals (called macro-segregations ) are significantly reduced.

The ESR remelted material improve following mechanical characteristics:

Improved toughness due to increased homogeneity and isotropyImproved creep resistance properties

Best fatigue strength and tenacity properties as well as outstanding tensile strength

Improved purity

Forging steel

The largest electro-hydraulic hammer is 4.5 ton. And more than 6 skilled technicians work for us. After forging, the inside

microstructure becomes much closer and the metal grain size becomes much smaller. It can evevate the characteristics and quality of the knife ensuring a longer life.

Rough processing

No less than 40sets of processing equipment in the rough processing workshop of Goodklife company, including lathe ,milling machine, planer, drill machine etc. Skilled workers are employed in its rough processing workshop.

Heat treatment

Goodklife company has independent workshop for heat treatment. Couples of skilled technicians work here. Actually, most blades ( thickness ≤100mm) can be fully hardened. Thus, the blades can be used after repairing until the size reached the minimum design dimension.

Finishing

Goodklife company has more than 35 sets of processing equipment including internal grinder, external grinder, surface grinder, CNC grinder, electric spark CNC wire-cut etc. The company can produce the shearing blades with 5500mm in length and slitting knives with 1500mm in outside diameter.

Testing

Various testers are put to use for testing its products in Goodklife company. They are including tensile tester, impact testing machine, metallography analyzer, harmless flaw detector, magnetic powder inspection, hardness tester, caliper rule , microcalliper, etc. Testing is carried out after each step. And every product has a unique track number. Thus it is easy to trace back anytime.

Company Introduction

Goodklife Machinery Technology Co., Ltd Ma'anshan is located in Bowang Town which is one of the most famous town for blades in China. The company has been committed to providing knives and blades of high productivity and high precision. By working with counterparts from western countries closely, Goodklife continues to innovate and pursues the better quality.

Certifications

Packing&Shipping

Packaging :

A. Inside packing: Applied with anti-rust oil and then packed in plastic bag

Packaging :

B. Outside packing: Packed in plywood case

Shipping :

FOB, CIF, DAP and etc. According to customers' requirements.

Our Advantages

Our Services & Strength

1,We made steel material on our own

2,We provide the custom material for customers

3,We have our own patent material

4,We have professional team to provide on-site training

5,Cooperation with many famous sea, air, courier forwarders

2,We provide the custom material for customers

3,We have our own patent material

4,We have professional team to provide on-site training

5,Cooperation with many famous sea, air, courier forwarders

6.Knives are available with polished side faces, High cost performance, Punctual delivery.

Material and hardness are much important to the work life of blades, according to over twenty years' experience. Goodklife will provide you professional advice. We will recommend you best material and hardness according to the applications of blades. We want to know the following details:

What kind of the steel?

The maximum tensile strength of the steel?

The minimum and maximum thickness of the steel?

We custom blades according to your drawing or description. In order to provide prompt and accurate quotation, it's better that you can provide us the quantity, drawings, cutting application and etc of blades.

All of your inquiry and emails, we will give reply within 24 hours. No excuse for failure ,only the action for success.

Our enterprise spirit: Mutually beneficial cooperation.

What kind of the steel?

The maximum tensile strength of the steel?

The minimum and maximum thickness of the steel?

We custom blades according to your drawing or description. In order to provide prompt and accurate quotation, it's better that you can provide us the quantity, drawings, cutting application and etc of blades.

All of your inquiry and emails, we will give reply within 24 hours. No excuse for failure ,only the action for success.

Our enterprise spirit: Mutually beneficial cooperation.

Buyer Praise

FAQ

1.What's price? |

We quoted based on your dimension, quantity, and material. |

2.What's the material and hardness? |

It depends on your material and application. Different material have different hardness. We will provide a most suitable hardness or your blades according to the application. |

3.If you do not know how to import the goods from our company, because it is your first time to import. |

We can provide DDU, DDP and courier express for you, then you can order and receive the goods like on ebay. |

4. Do you provide free samples? |

Yes, usually we provide free samples for testing under the condition of freight paid by customer. |

If you are interested in our products, you can contract us any problem. We are glad to help you. |

Похожие товары

Режущее круглое дисковое лезвие и нож промышленное режущее по индивидуальному заказу для

95,00 $ - 150,00 $

Прямая поставка с завода бытовая бумага для постобработки продольное круглое лезвие плоское машина изготовления

18,00 $ - 23,00 $

Другая многофункциональная машина для поперечной резки bladee нож

Oem/odm Tc длинный прямой бумажный Гильотинный лезвие струбцина режущий нож для машины из гофрированного

75,53 $ - 77,23 $

Ножи для резки и с режущим лезвием из быстрорежущей

Вращающиеся ножницы для резки режущее лезвие диаметром 610 мм лезвия бревен машины туалетной

Продольно-режущее полотно для плёнки с отверстиями по хорошей

2,50 $ - 3,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $