Автоматическая машина для розлива морепродуктов/томатного соуса

- Категория: >>>

- Поставщик: Guangdong Xtime Packaging Equipment Co. Ltd.

Сохранить в закладки 1600089609087:

Описание и отзывы

Характеристики

1. The machine is suitable for connecting to a whole production line.

2. Quality is reliable, simple operation and durable,it is the ideal equipment for liquid filling.

3. Metal can capping machine provides customization according to customer's product.

1. To replace different types of bottles, the mechanical position of the filling bottle cylinder, the filling bottle cylinder, the filling bottle electric eye, the filling bottle electric eye, the bottle cylinder and the filling nozzle must be adjusted.

2. Filling the bottle with the electric eye must be aligned with the bottleneck of the last bottle. That is, when the bottle is automatically run, the 8th bottle must be placed in the range of the electric eye to be filled into the bottle. The bottle is not cut until the time set by the “Pilling Time” (set in the “Parameter Setting” of the HMI) is reached before the electric eye.

3. Filling and filling the bottle electric eye is installed in the slightly right position of the cylinder of the bottle. When the bottle is started, the cylinder of the bottle is extended, and the cylinder of the filling bottle is retracted; after a number of bottles (which can be set in the “out of the bottle interval” of the human-machine interface), the bottle is retracted and the bottle is started. After all the bottles have gone out (after filling out the bottle electric eyes), the filling bottle cylinders are extended.

4. When filling the bottle and discharging the bottle, the electric eye must be counted in 8 numbers before proceeding to the next step. The user can observe whether the number of bottles and bottles is 8 in the automatic operation screen of the man-machine interface.

Speed | 30-60 bottles/min(customized) | ||||||

Accuracy | +-1% | ||||||

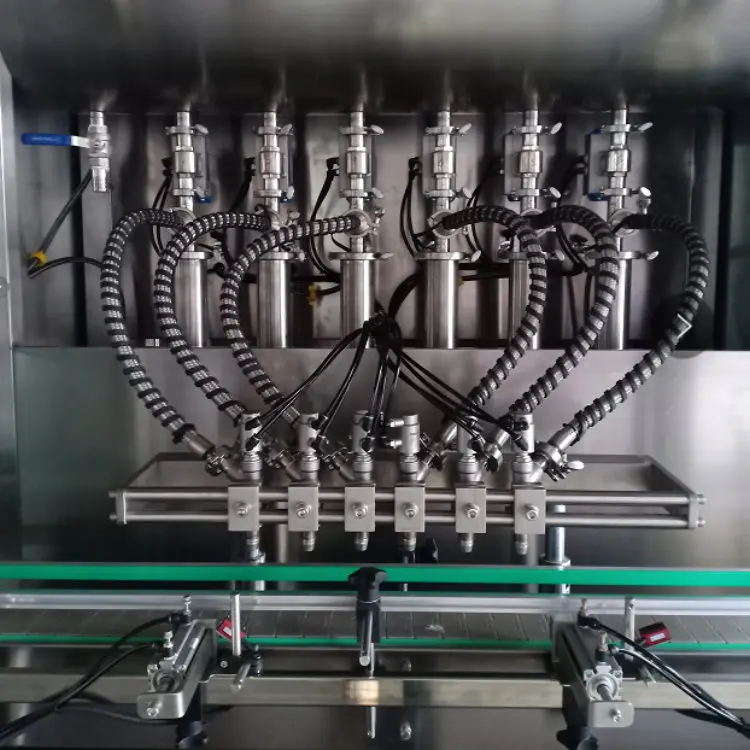

Filling type | Self-flow type | ||||||

Power | 3KW 220V/380V | ||||||

Control | Simen PLC+Touch screen | ||||||

Machine size | 1500*800*1800mm | ||||||

Quantity of filling heads | 4/6/8/10/12(customized) | ||||||

Filling range | 250-2500ml | ||||||

Brands we use for electric components:

Competative price!

Good and patient team!

Experienced technicians and technolgy!

Good reputaion!

FAQ:

Q1: How to find a Packing machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to pack?

2. The bag/sachet/pouch size of you need for the product packing ( the length, width).

3. The weigh of each pack you need.

4. You requirement for the machines and the bag style.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placking the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use alibaba trade assurance service,guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1.Sign the Contact

2.Arrange 30% deposit to our factory

3.Factory arrange production

4.Testing & detecting the machine before shipping

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

A: Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.

Похожие товары

Упаковочная машина для кожи, вакуумная упаковочная машина для креветок/морепродуктов/мяса, вакуумная упаковочная машина для кожи

Мини-холодильник для морепродуктов/рыбного мяса

Многофункциональная Автоматическая вакуумная упаковочная машина VSP для рыбьей кожи, Модифицированная атмосфера морепродуктов, вакуумный упаковщик-лоток, карта, мясо, продукты питания

Сделано в Китае, морозильная камера IQF, туннель, курица, морепродукты и овощи

Машина для упаковки пакетов, картофельных чипсов, жареных арахиса, свежих морепродуктов, лапши

Горячая Распродажа Термоформовочная многофункциональная упаковочная машина для мяса/морепродуктов/курицы/говядины/колбасы автоматическая вакуумная и упаковочная машина

Автоматическая машина (плоская) для курицы, говядины, морепродуктов и другого мяса

Новые поступления

Новинки товаров от производителей по оптовым ценам