Универсальная резиновая заглушка в виде гриба для ремонта бескамерных шин

- Категория: >>>

- Поставщик: Cangzhou Yaqiya Auto Parts Manufacture Co. Ltd.

Сохранить в закладки 1600094109612:

Описание и отзывы

Характеристики

Universal Tubeless Tire Puncture Repair Mushroom Plug Patch Gum for Car

Selling Points

1. Combined patch/plug tire repair for punctures to the tread of both radial and cross-ply tires.

2. Repair units self-vulcanize in the tire.

3. The tire inside and puncture channel are repaired in one operation.

4. The ingression of moisture, dirt, stones or all materials that lead to premature deterioration of the casing and belts is prevented.

Description

Plug repair unit require no special wire pulling tools. Just insert the plug into the injury from the inside of the tire and pull the repair unit through from the outside. Both the stem and the repair unit are gum coated to provide the most complete bond, both through the injury and on the inner liner. The plug repair patches are black with gray vulcanizing gum and will vulcanize chemically or in a heat curing system.

Box of 24 plugs to repair a 6mm injury to a tyre. Repairs the hole and surface with one product, protecting against leaks and seals against humidity.

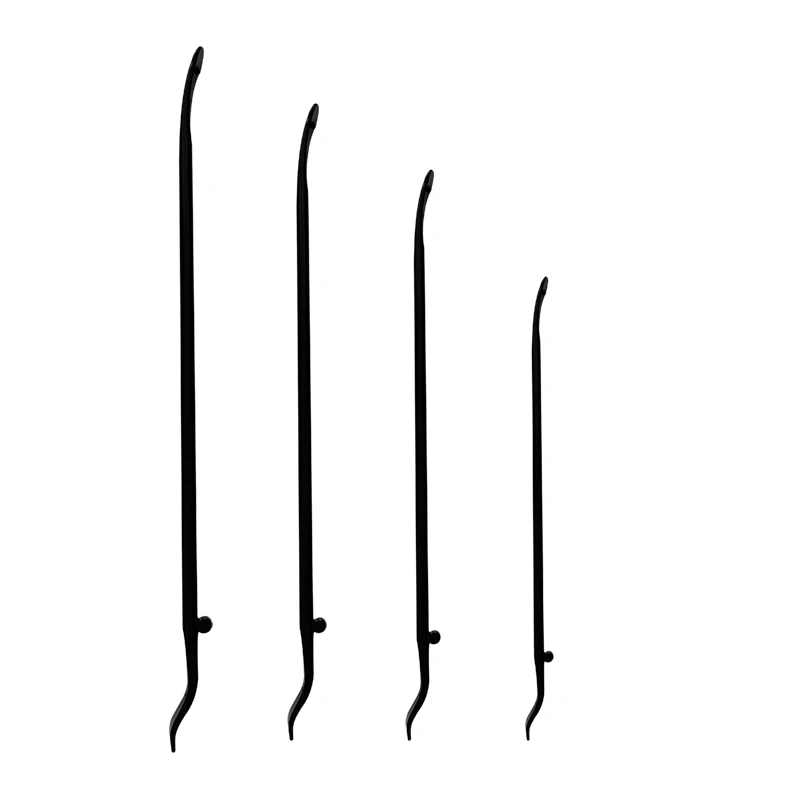

| Part No. | Description | Box Qty | Case Qty |

| TPP-264 | Patch Size 1" (26mm), Stem Dia. 3/16" (4mm) | 60 | 36 |

| TPP-364 | Patch Size 1 1/2” (36mm), Stem Dia. 3/16" (4mm) | 24 | 36 |

| TPP-366 | Patch Size 1 1/2” (36mm), Stem Dia. 1/4" (6mm) | 24 | 36 |

| TPP-466 | Patch Size 1 3/4” (46mm), Stem Dia.1/4" (6mm) | 24 | 36 |

| TPP-509 | Patch Size 2" (50mm), Stem Dia. 3/8" (9mm) | 24 | 27 |

| TPP-606 | Patch Size 2 3/8" (60mm), Stem Dia. 1/4" (6mm) | 24 | 27 |

| TPP-609 | Patch Size 2 3/8" (60mm), Stem Dia. 3/8" (9mm) | 24 | 27 |

| TPP-6812 | Patch dia.68mm. stem dia.12mm | 24 | 27 |

| TPP-1014 | Patch Size 4"(100*100mm), Stem Dia.9/16"(14mm), Square Shape | 24 | 12 |

| TPP-1018 | Patch dia.100mm, stem dia.18mm | 24 | 12 |

INSTRUCTIONS

1. REPAIR PROCEDURES FOR COMBINATION REPAIR UNITS

Before repairing, mark and remove puncturing object. With tyre inflated, apply soap solution to damaged area to determine if air loss is from one or more punctures. Remove tyre from wheel carefully to avoid further damage and place on spreader.

2. PROBING

Probe puncture to determine size and direction of injury, making sure to remove all foreign materials. DO NOT repair it when injury is beyond puncture repair limits.

3. INTERNAL EXAMINATION

Spread the beads and mark the damaged area with a crayon. Carefully inspect tyre to ensure that all damage is within repairable limits. If limits are exceeded, DO NOT repair the tyre.

4. REPAIR UNIT SELECTION

If injury is 1/4''(6mm) or smaller in diamater and angle does not exceed 25Y, a combination repair unit is the easiest method of repair. Reinforced Combination Units are for tread area only Universal and Lead-Wire Combination Units may be used in any repairable area.

5. CLEANING

Using buffing solution and an inner scraper, clean thoroughly an area slightly larger than the patch head of the repair unit. This serves to remove dirt and mold lubricants for better adhesion.

6. BUFFING

Using a buffing wheel, buff repair area to texture taking care not to gouge the inner liner. Using appropriate reamer of cutter(for lead-wire units), drill injury channel from inside and from outside, removing damaged cables and debris. Vacuum away buffing dust.

7. CEMENTING

Apply vulcanizing cement to the injury channel and prepared repair area. Work cement into the rubber. DO NOT puddle or scrape pff. ALLOW CEMENT TO DRY THOROUGHLY.

8. INSERTION

Remove backing from patch head(and stem fo Lead-Wire Units) DO NOT touch gum surface. Push quill or lead wire into the injury from inside and pull through with pliers. Pull until patch head is seated firmly against the inner liner.

9. FINISH REPAIR

Thoroughly stitch the patch bead to the inner liner working from the center outward to remove any trapped air. Cut the stem 1/8'' above tread surface. Apply Inner Liner Sealer to overbuffing area and allow to dry.

Cangzhou YAQIYA Auto Parts Manufacturer Co., Ltd is located in Huaizhen Industrial Zone, Xianxian, Cangzhou city, Hebei Province, China, which specializes in manufacture and export various of wheel balance weights (adhesive wheel weights, clip on wheel weights), tire valves (tubeless tire valve, tr412, tr413, tr414, TPMS valves, truck tire valves), tire repair seals (tire plug), tire repair patches (cold patch), tire repair tools, tire mounting paste and so on.

The YAQIYA company has been developed very fast, the enterprise management, employe quality, technical equipment, production technology and supporting facilities, etc. All have achieved international standards, so that the company take the leading position in the same field in the country. At present, with an annual output of 3000 tons for various wheel weights.

COSTOMER CHOICE

You can also choose

| 1. Why Choose Us? |

| We are a more than 10 years professional manufacturer in car accessories with high quality and competitive price. |

| 2. What's your auto fastener guarantee? |

| Strictly complying with quality management systems of ISO 9001 and SGS. If you have any problems concerning quality, we will offer you a refund or a replacement. |

| 3. How many quantities about packing for each item? |

| Without quantity limitation for inventory goods; more than 2000 pcs/item for customization order. |

| 4. How long is the date of deliverly? |

| If inventory goods, we will delivery within 2 working days. For a customized order, within 30-60 days. |

Похожие товары

DW-95 MASUMA авто аксессуары набор для ремонта шин ACV31L 1azfe Авто ремонтная мастерская D90mm

BW-75 MASUMA профессиональным поставщиком Авто холодной патч для ремонта шин ACA20L 1azfe ремонтная мастерская автомобиля 50x75mm

R-2 MASUMA холодной патч клей для KE # 92000cc для авто ремонтная мастерская

BWG-05 MASUMA производитель заплата для ремонта шин клей для задавайте для ремонта автомобилей D210mm

Авто 12 В Электрический воздушный компрессор автоматический воздушный компрессор

Низкая цена, высокое качество, рычаг для шин, вакуумный кронштейн для монтажа и демонтажа грузовых шин

Инструмент для ремонта автомобиля, пневматическая шина с бортиком, 10 галлонов, шина с мгновенной накачкой, усилитель шин

Новые поступления

Новинки товаров от производителей по оптовым ценам