Автоматические плоские стыковые сварочные стенды по заводской цене продольные машины

- Категория: >>>

- Поставщик: Shandong Shuipo Intelligent Equipment Co. Ltd.Shandong Ltd.

Сохранить в закладки 1600095117908:

Описание и отзывы

Характеристики

1.About the product

Brief introduction

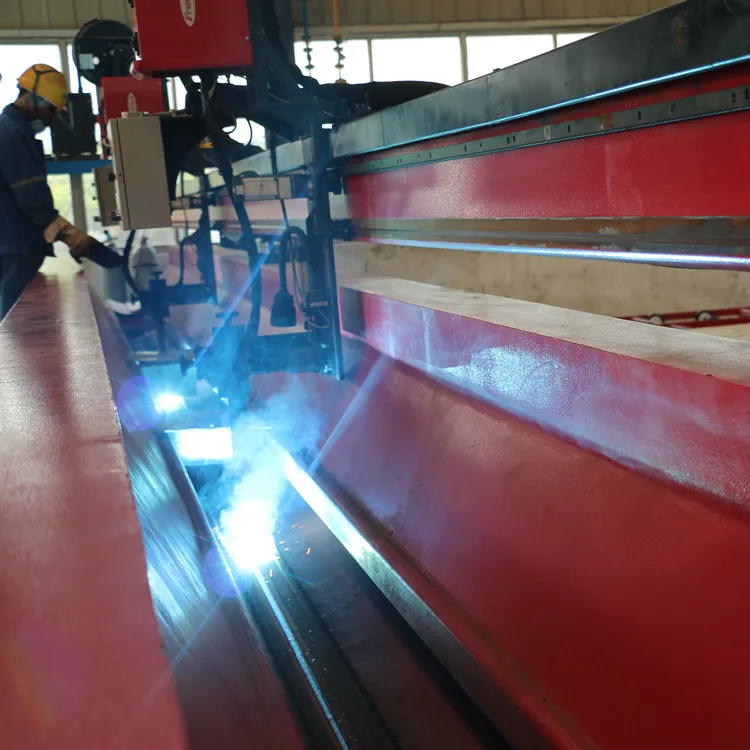

The automatic flat butt welding machine exclusively designed and developed by Shandong Shuipo Welding&cutting Equipment Manufacture Co.,Ltd based on years welding experience and equipment debugging skills,which brake traditional tank producing patten.It adopts pneumatically piano-key clamping device,it improves quality by leapsand bounds.The seam can be welded for one side or for both sides.There is no minimal deformation.There are clean and beautiful seam on both sides,round and smooth transfers.Frame is made up of steel structures,which feature high strength and less deformation.Inlet and Out are equiped with universal balls.Welding device consists of feeder,torch,torch-adjusting mechanism and slides,etc.And also lighting system has been employed.Red cooper is made into molding groove which adopts water cooling.There processed molding grooves on both sides.And machine is equipped with center positioning device and fast separation device of molding groove against welding seams.

Part of the Workpiece and the Effect of Processing

The machine includes a long bench, a key compact device, a beam, a platform, a central orientation device, a pipe assembly and a welding cart. With the wire-feeder, the welding generator and the gas pipe can finish the welding work. The bench is strong enough to endure the compact pressure. The cylinder keyboard compacts the board equally. The welding speed is controlled by the DC motor, fulfilling the stepless adjustment and convenient operation.

The Utilization Site

To ensure that the steel is flat, the seam can be welded for one side or for both sides. There is no minimal deformation. Thereare clean and beautiful seam on both sides, round and smooth transfers. The deviation on the back side is no larger than ±0.5mm, with the obverse no larger than 2mm and the reverse side 1mm. The width of the welding seam is 5-12mm

The Technical Statistics

The Welding Length(can be customized) | 9500mm | The Adjustment of the Welding Speed | The Stepless Adjustment |

The Welding Metal Base | Q235A,16Mn,SUS304 | The Welding Speed | 100-1500mm/min |

The Thickness of the Metal Base | 3-8mm | The Operation Precision of the Welding Torch | The Welding Torch can be Adjusted by Hand or Electromotion |

The Pressure of the Pneumatic System | 0.4-0.8MPa | The Effect of the Welding Seam | One-Side is Welded; Two Sides are Shaped. |

The Way of Pressing the Work Piece | The Cylinder Keyboard Pressed | The Dead Weight |

20ton

|

2.Other products

3.About our company

Our company mainly specializes in the researching,developing and manufacturing equipment for special vehicle and commercial vehicle.We have the ability to design the whole production line according to your specifications.We have developed 96 kinds of welding and cutting equipment in 28 series,including automatic tank seam welding machine ,automatic welding robot ,automatic welding machine for dumper truck,automatic dish head bending machine,automatic dish head spinning machine,gantry H-beam welding machine , CNC cutting machine ,plasma cutting machine and etc,.Our products are used by more than 1000 manufacturers of special and commercial vehicles domestically

,including China FAW,CIMC,and export to 200 enterprises in 40 countries and regions,such as Germany,American,Canada,Australia and Brazil,and earn high reputation both at home and abroad.It has now taken up to above 70% of the market share in the domestic special welding and cutting equipment market.

Похожие товары

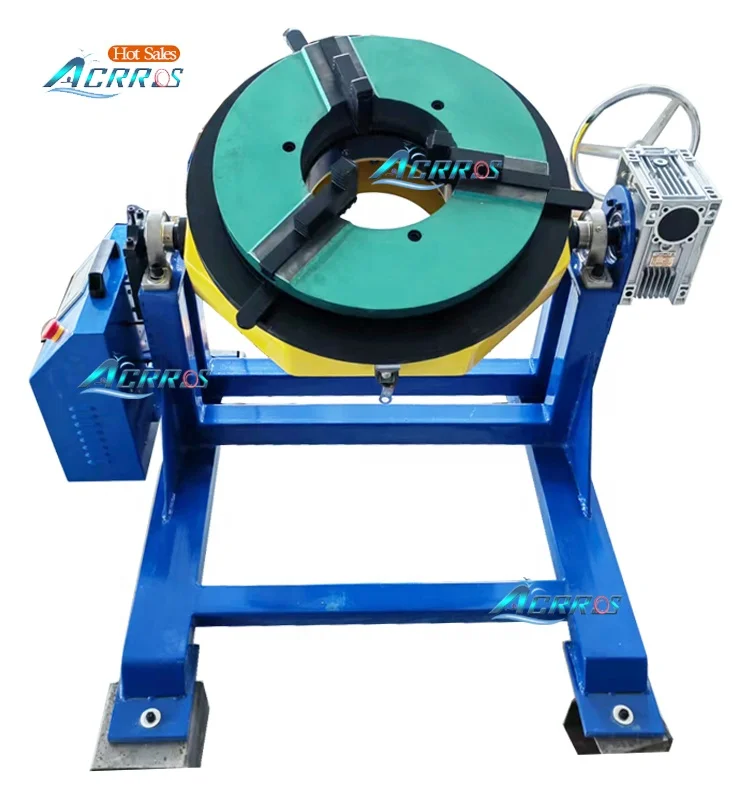

Вращающийся сварочный стол с отверстием 240 мм 500 кг 600 позиционер сварочной трубы

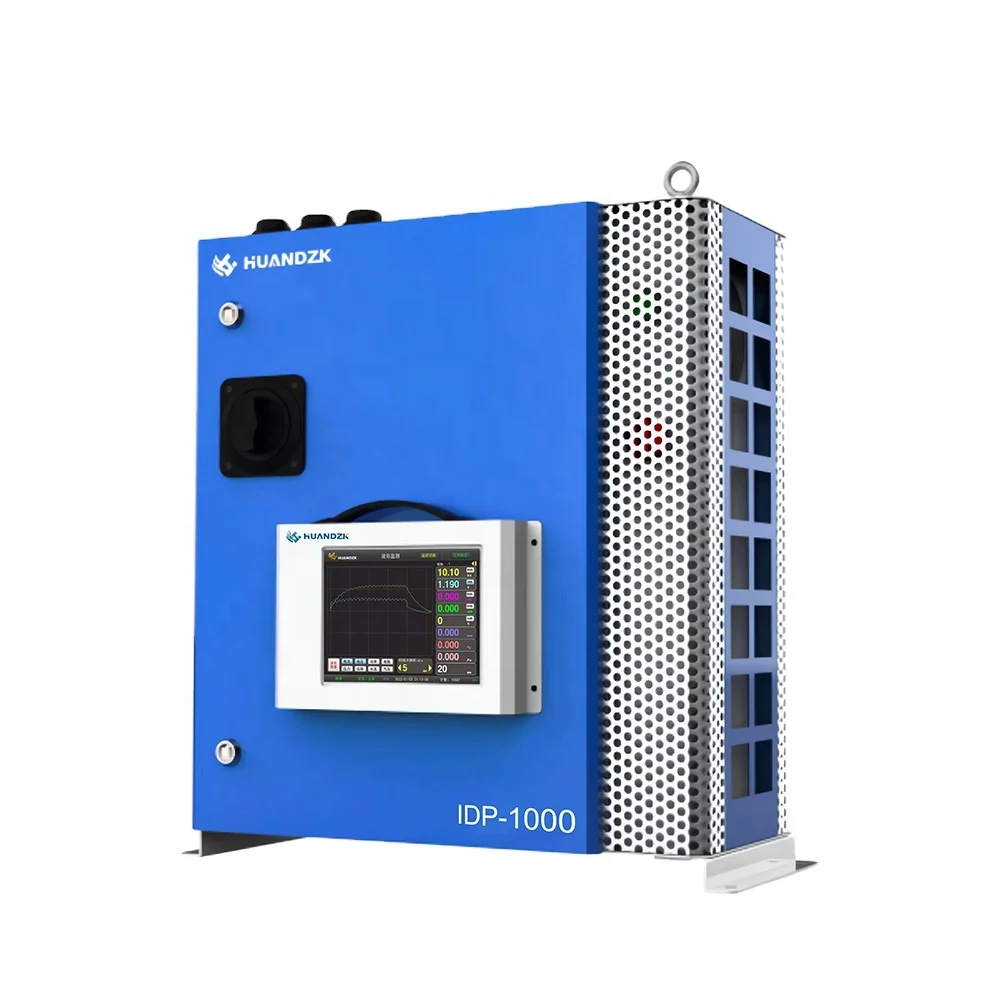

Высокочастотный сварочный робот машина источник питания сопротивление IDP-1000

Сварочная тележка сварочный робот рука многофункциональный промышленный беспроводной пульт дистанционного управления

Сварочная рабочая станция японская заводская цена AR1440 технология MIG-MAG с megmelet CM350 или OTC сварочный аппарат Сварочный позиционер по индивидуальному заказу

Дешевая Автоматическая волновая паяльная машина оборудование для селективной пайки с флюсовым баком

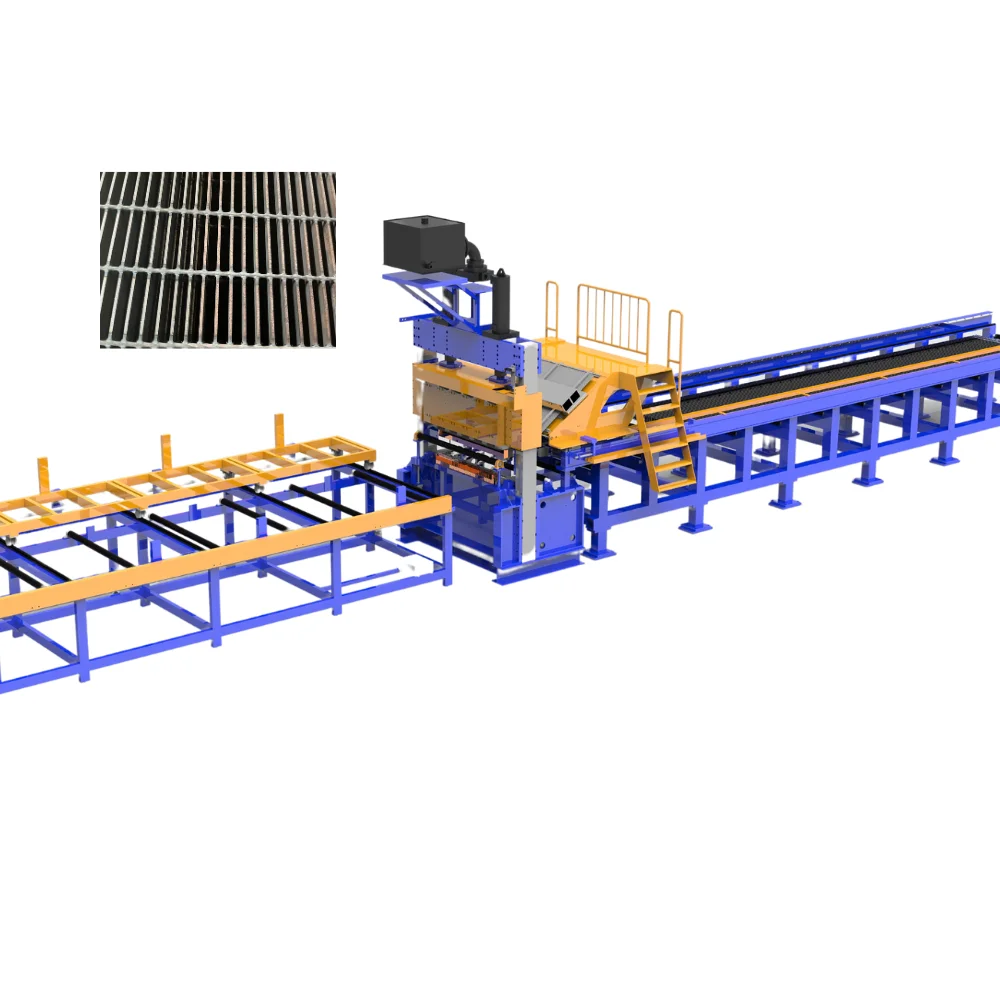

Машина для производства стальной решетки Электро кованый сварочный аппарат сварки ферм

Станция для переделки BGA Bauer IR PRO SCC V.4 инфракрасный + горячий воздух все в одном BGA.

Новые поступления

Новинки товаров от производителей по оптовым ценам