SGK 160 автоматический R типа U Тип пластик PVC PP PE Трубогибочные socketting машина

- Категория: Раструбные станки >>>

- Поставщик: Nantong Bogda Machinery Technology Co. Ltd.

Сохранить в закладки 1600095526397:

Описание и отзывы

Характеристики

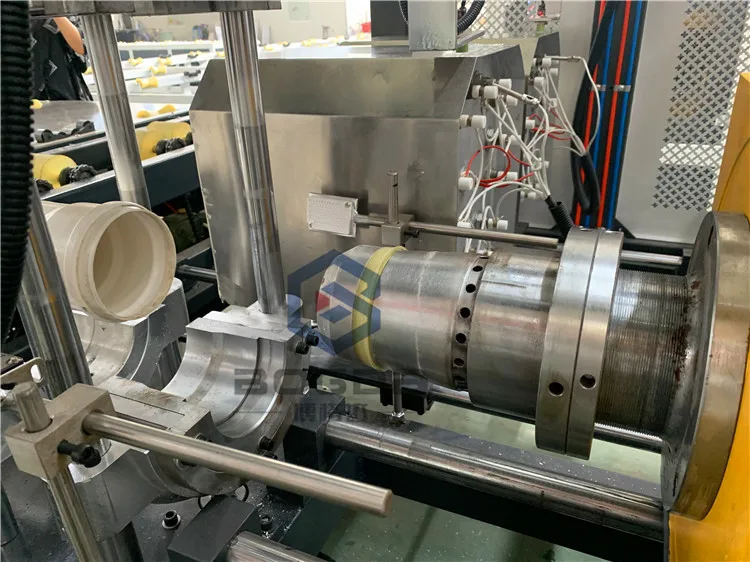

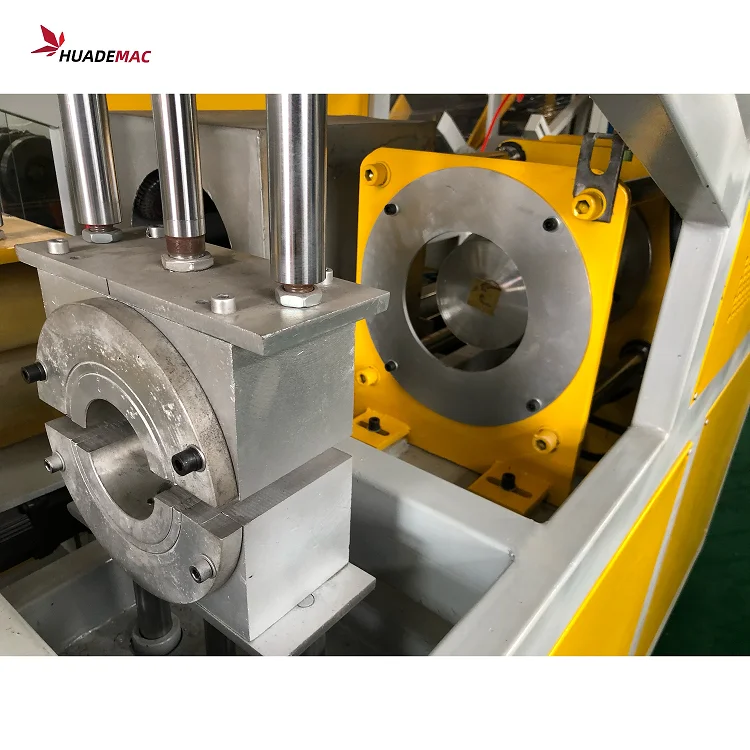

Fully Automatic PVC Pipe Belling Machine

PVC pipe belling machine is a semi-automatic machine, which can be used as a single machine. The machine USES infrared heating; The forming methods are all shaped by expanding pipe head, and the forming size of pipe mouth is accurate. The control panel of this machine is equipped with a switch of expanding solvent socket (straight port) and expanding elastic sealing ring socket (R port). Mainly electrical control components are imported components, the system performance is stable and reliable.

Suitable for the R type ,U type and Rectangle plastic pipe

Main Features

1)The equipment has high degree of automation and stable and reliable performance.

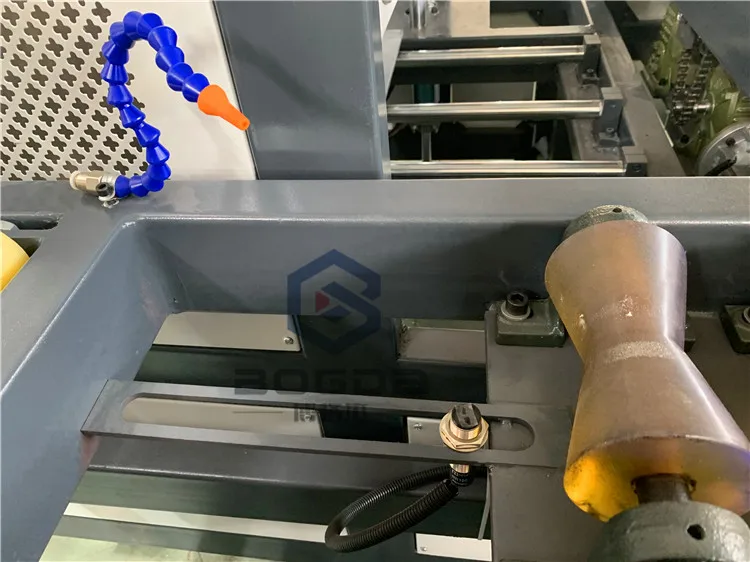

2)The air duct material is made of stainless steel, which can ensure no high temperature iron oxide falling off in the process of drying the pipe and cause the pipe head scar spot.

3)The frame is made of cold-drawn rectangular steel pipe welded with high rigidity and reasonable structure.

4)Cooling by air pressure cooling, no damage to the mold and no pollution.

Functional specification

1. Pneumatic propulsion heating furnace, heating furnace can be fine-tuned high and low and feed limit, electric heat pipe semi-open indirect heating, rotating speed by the manufacturer design (timing positive and negative).

2. The center of the machine is adjusted as a point-moving electric chain drive lifting, with a high center of about 1 meter

3. The hosting rack is 4.8m, and the fitting pipe length is 4-6m

Technical Parameter

Model | Pipe Diameter | Heating Method | Belling Method | Heating power | Dimension |

SGK110 | 50-110mm | Electric heating | Mould physical expansion | 10.5kw | 7500x1400x1750mm |

SGK160 | 50-160mm | Electric heating | Mould physical expansion | 10.5kw | 7500x1400x1750mm |

SGK200 | 50-200mm | Electric heating | Mould physical expansion | 10.5kw | 7855x1350x1900mm |

SGK250 | 110-250mm | Electric heating | Mould physical expansion | 10.5kw | 7830x1620x1700mm |

The length of the flaring part is positioned with the photoelectric switch, so that the length of the flaring is basically the same. The flaring mold base can be fine-adjusted into a limited amount, and the flaring can be used in the mechanical oil before and after the flaring pressure, hydraulic source equipment.

1. The control system adopts man-machine interface, Chinese and English menu touch screen, Siemens. And PLC automatic programming system, to achieve automatic control

2. The machine is equipped with automatic stripping equipment

Final pipes

Pre-sale services:

Based on the clients' request and budget, we will offer equipment pictures, working site videos, plant processing diagram, assemble drawings, foundation drawings, and plant layout. Clients are welcome to visit our factory, also our equipment working site from former clients.

Sale services:

Our experienced technicians are available on the phone also the Internet, clients can get instance guidance by telephone, email, online service anytime and anywhere.

After-sale services:

Normally, the equipment warranty is 12 months since installation. To establish long term cooperation, we will regularly call and email our clients to check the equipment working condition and offer suggestions for maintenance.

How many electric, water, air need for the machines?

BOGDA: technical department supply the whole layout for workshop details.

Can I operate machine if don’t have experienced engineers?

BOGDA: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

Any quality checking before shipment?

BOGDA: 100% confirm, run and test machines before shipment with quality certificate.

How long is the guarantee?

BOGDA: 12 months since the first day customer operates (except wear parts)

How can u help us when face some technical problem?

BOGDA: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

Where can we get spare part?

BOGDA: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.

Похожие товары

16-630 мм пластиковая машина для развальцовки труб из полипропилена на продажу

Машина для розеток ПВХ труб/машина для скручивания труб из ПВХ

Sevenstars полуавтоматическая ручная машина для прокладки ПВХ труб PP

Автоматическая машина для скручивания ПВХ труб с различным острым стилем

Доступная автоматическая машина для производства пластиковых труб в духовке с U R J style

Низкое энергопотребление, двойная духовка, автоматическая машина для прокладки труб PP PE

Сильная дробильная машина для ПВХ труб, машина для изгиба труб из ПВХ

Новые поступления

Новинки товаров от производителей по оптовым ценам