Шаровая мельница Hongxing с большой емкостью и резиновой прокладкой для позолочения/меди/зиновой руды

- Категория: >>>

- Поставщик: Henan Hongxing Mining Machinery Co. Ltd.

Сохранить в закладки 1600097932596:

Описание и отзывы

Характеристики

- Ball mill introduction

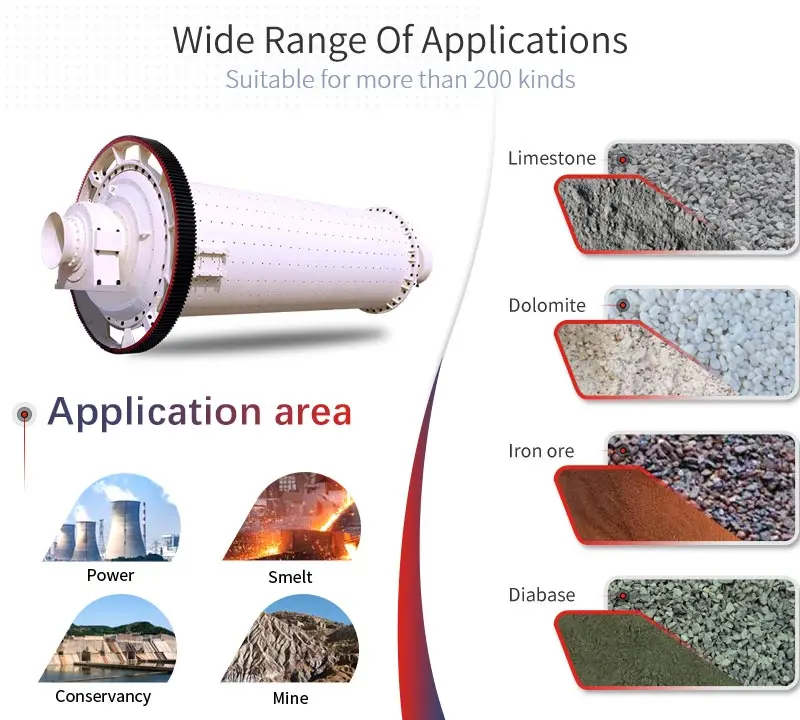

Ball mill is the key equipment for grinding the material after being broken. Ball mills are widely used in cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings, and glass ceramics. The ball mill is suitable for grinding various ores and other materials and is widely used in mineral processing, building materials and chemical industries.

- Classification Of Ball Mill

The ball mills can be divided into dry ball mill and wet ball mill according to the process conditions.According to different materials will choose different grinding sub. The grinding sub can be roughly divided into metal and non - metal categories. The grinding sub of ball mill is steel ball, the grinding sub of rod mill (MBS type rod mill) is a steel bar, and the grinding sub of ceramic ball mill is ceramics.

Wet ball mill: Grind the material into a certain concentration of pulp, the general concentration is 60 ~ 70%.

Dry ball mill: Grind the material into the desired mineral powder. The thickness of the ore powder should be based on the grading of the grinding body.

- Ball Mill Features

Energy Saving and Less Power Consumption: The matching of the drive and the grinding media can greatly lower the power consumption.

The Flexible Design of the Discharging Port: The customers can decide whether the iron removing the device is required or not according to their demands.

The Bigger Feeding Size: The reasonable design of the feeding port can increase the feeding output.

Taking the Closed System to Decrease the Dust: Closed system, negative pressure conveying, small dust.

- Ball Mill Working Principle

The material is fed into the mill by a drum feeder through a spiral cylinder with a hollow shaft. The grinding medium is installed in the barrel body. When the barrel body rotates, the grinding medium is attached to the wall liner surface of the barrel body due to the inertial centrifugal force. After being rotated together with the barrel body and brought to a certain height, the materials in the barrel body are broken by gravity.

In addition to the cyclic movement of ascending and falling, the grinding medium also causes sliding and rolling in the rotating cylinder body, causing grinding action between the grinding medium, the lining plate and the material to grind the material.

- OUR COMPANY

- FAQ

What about the quality of your products?

Our products are manufactured strictly in accordance with the national and international standard, and we always test every equipment before the delivery.

Is the price of products reliable?

Yes, we are manufacturer and we have the strength to give you the lowest price compared with other dealers. However, we have the policy that "According to the quantity order, we will offer the lowest price as possible with our utterly honest attitude towards business ".

In order to help you get a suitable machine and provide you a preferential quotation,

Pls kindly provide the following information:

1. What's the materials to process?

2. What's the feature of the materials? Like density, moisture degree,input particle size and out put particle size.

3. What's your capacity per hour?

4. What's material for the machine?

5.What's the machine you want to buy?A single machine or a production line.

Похожие товары

Продукты mas vendidos в Китае низкая цена переливная шаровая мельница с резиновой прокладкой для пользования золотой рудой

Высокоэффективное оборудование для переработки минеральной руды смесительный резервуар для добычи полезных ископаемых

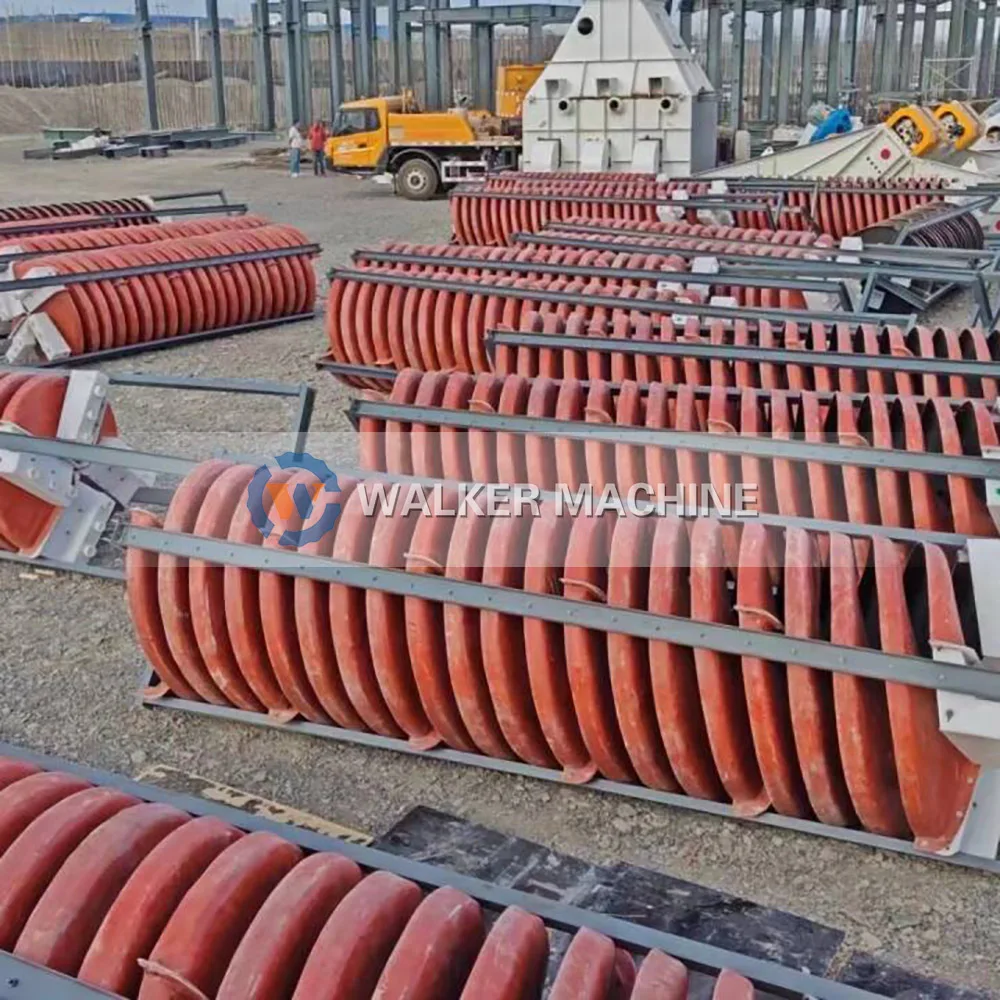

Спиральный гравитационный сепаратор для добычи олова

10TPH хромитовый гравитационный спиральный желоб минеральный спиральный концентратор оборудования

Железнодорожная алюминиевая Тепловая Сварка передвижное железнодорожное сварочное оборудование бесшовная железнодорожная алюминиевая Тепловая сварка

Высокое качество фильтрации и разделения горнодобывающего оборудования роторная дисковая вакуумная фильтровальная машина

Эксперт в области бурового наконечника резьбового наконечника 43 мм направляющая резьба TR35 буровая насадка бурового инструмента

Новые поступления

Новинки товаров от производителей по оптовым ценам