Установка для обжига магнезитов оборудование вращающаяся печь

- Категория: Cement Making Machinery >>>

- Поставщик: Henan Zhengzhou Mining Machinery Co. Ltd.Henan Ltd.

Сохранить в закладки 1600101559822:

Описание и отзывы

Характеристики

Dead Burned Magnesite Calcination Plant Equipment Rotary Kiln

- At present, light-burned magnesite mainly uses rotary kiln equipment.

- Magnesite rotary kiln of Henan ZK Corp produced has 11 models.

- Provide the whole service for magnesite, dolomite, lime calcination plant.

ZK Corp produces Rotary Kiln with the diameter1-5 meters, widely applies in the metallurgy, the chemical industry, bears professions and so on material, Ceram site, papermaking. This kind of kiln’s supporting is divided into two forms of rolls and skids, the transmission may use direct-current or the exchange frequency conversion velocity modulation, and has many kinds of form seals to adapt the different operating mode.

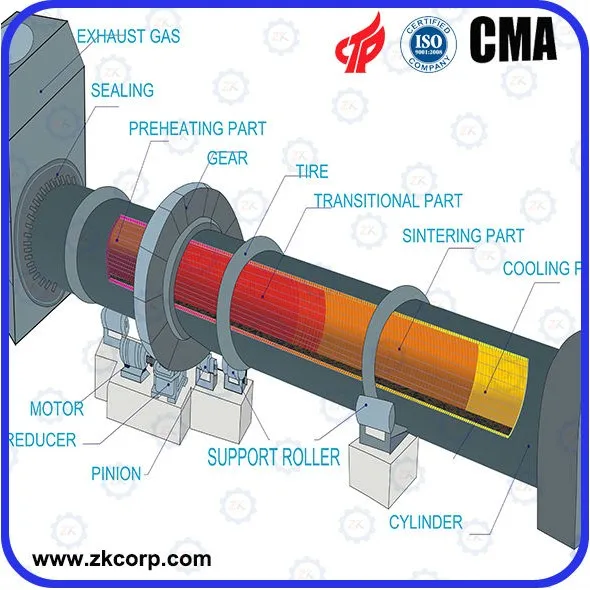

ZK Corp could also meet different needs from different customer to produce Non-standard Rotary Kiln. Rotary Kiln is composed of cylinder, gears, supports device, kiln liner and kiln tail sealing equipment, kiln head hood, and combustion. Cylinder as heated pivoting part, made of high-quality carbon steel plate, is supported on the first or some gear in order to control the turning of cylinder. Gearing gyrate according to process-required rotating speed by ring gear in the middle of cylinder. Because of the need of installation or maintenance, bigger rotary kiln has auxiliary gears, which makes cylinder gyrate more slowly. To prevent cold air come in and dust overflow, the reliable kiln tail and head sealing equipment is installed on feed and discharge end.

Product feature:

1. Support device: advanced shaft structure, automatic temperature measuring device and electrical heating.

2. Catch wheel: including two kinds mechanical wheel and hydraulic pressure.

3. Gears: single or double. Control the rotating speed by variable motor, DE machine and frequency variable motor. Be reliable, energy –saving, and efficient.

4. Cylinder tyre bolster: lower bolster has three types: fixed, zoom and floating. The structure is simple, replacement is convenient and won’t hurt cylinder.

5. Sealing equipment: there are many kinds for choice according to kiln models, including air cylinder edge sealing, spring edge sealing, and graphite block sealing and combination for above. The feather is adaptive for cylinder rotating and swing. And sealing effect is very good.

6. Kiln head hood: including stationary type and flexible type.

Rotary Kiln Specifications:

| spec (m) | technical parametere | speed reducer | motor | supporting quantity | |||

| rev (r/min) | slope (%) | output (t/h) | type | type | power (KW) | ||

| Φ1.6X32 | 0.58~2.85 | 4 | 2 | ZQ75-50 | YCT250-4A | 18.5 | 3 |

| Φ1.6/1.9X36 | 0.53~1.59 | 4 | 2.5~3 | ZQ110-7 | YCT250-4B | 22 | 3 |

| Φ1.9X39 | 0.53~1.59 | 4 | 3~3.4 | ZQ125-7 | YCT315-4A | 37 | 3 |

| Φ2.2X45 | 0.214~1.64 | 3.5 | 4~5 | main:ZS125-5 | YCT315-4B | 45 | 3 |

| auxiliary:ZQ40-40 | Y112M-4 | 4 | |||||

| Φ2.5X50 | 0.62~1.5 | 3.5 | 5~6 | main:ZS165-5 | YCT355-4A | 55 | 3 |

| auxiliary:ZS50-1 | Y160M-6 | 7.5 | |||||

| Φ2.5X55 | 0.62~1.5 | 3.5 | 5~6 | main:ZS165-5 | YCT355-4A | 55 | 3 |

| auxiliary:ZS50-1 | Y160M-6 | 7.5 | |||||

| Φ2.8X55 | 0.62~1.5 | 3.5 | 6~7 | main:ZS165-6 | YCT355-4B | 75 | 3 |

| auxiliary:ZS50-1 | Y160L-6 | 11 | |||||

| Φ3.0X60 | 0.5~1.5 | 3.5 | 7~9 | main:ZS165-3 | ZSN-280-11B | 125 | 4 |

| auxiliary:ZS50-1 | Y160L-6 | 11 | |||||

| Φ3.2X64 | 0.4~1.5 | 3.5 | 8~10 | main:ZL130-16 | ZSN-280-11B | 190 | 4 |

| auxiliary:ZL50-10 | Y180L-4 | 22 | |||||

| Φ3.5X70 | 0.4~1.5 | 3.5 | 12~14 | main:ZSY500-40 | ZSN-315-082 | 280 | 4 |

| auxiliary:ZL50-14 | Y180L-4 | 22 | |||||

| Φ4X80 | 0.4~1.5 | 3.5 | 16~20 | main:ZSY630-35.5 | ZSN-315-12 | 355 | 4 |

| auxiliary:ZSY280-35.5 | Y200L-4 | 30 | |||||

Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment

according to your special demand.

Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators

and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory

level of spare parts, which means the replacements can be shipped to you right away.

1. What's the biggest rotary kiln diameter you can make ?

φ4m

2. How about the material quality control ?

Ultrasonic Fault Detection

3. How to control the fire temperature

By sensor and PLC system

Похожие товары

Гипс производитель роторной печи для цемента китайский лаймов гипсового роторная печь цена

Китайская новая технология оборудование для переработки обжига известняковой печи

Промышленное оборудование для сушки песка вращающаяся барабанная сушилка от производителя

Гипсовая печь для обжига порошка

Вращающаяся Песочная печь для керамики 100tpd строительной промышленности

Высокоэффективная двухкамерная шаровая мельница для горнодобывающей промышленности передовая линия по измельчению и дроблению

Вращающаяся барабанная печь 100TPD для кальцинирования Eaf вращающаяся из оксида цинка продажи

Новые поступления

Новинки товаров от производителей по оптовым ценам