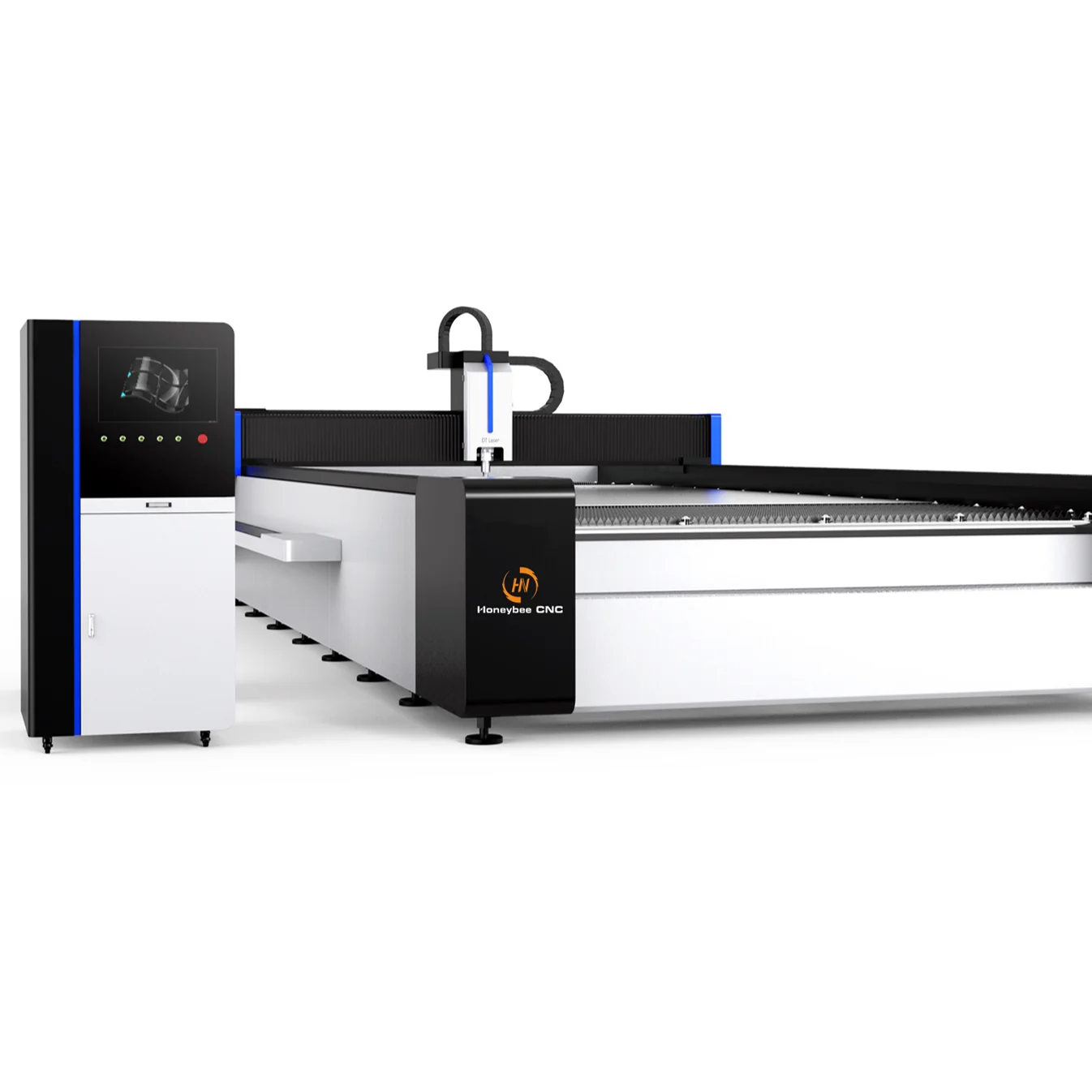

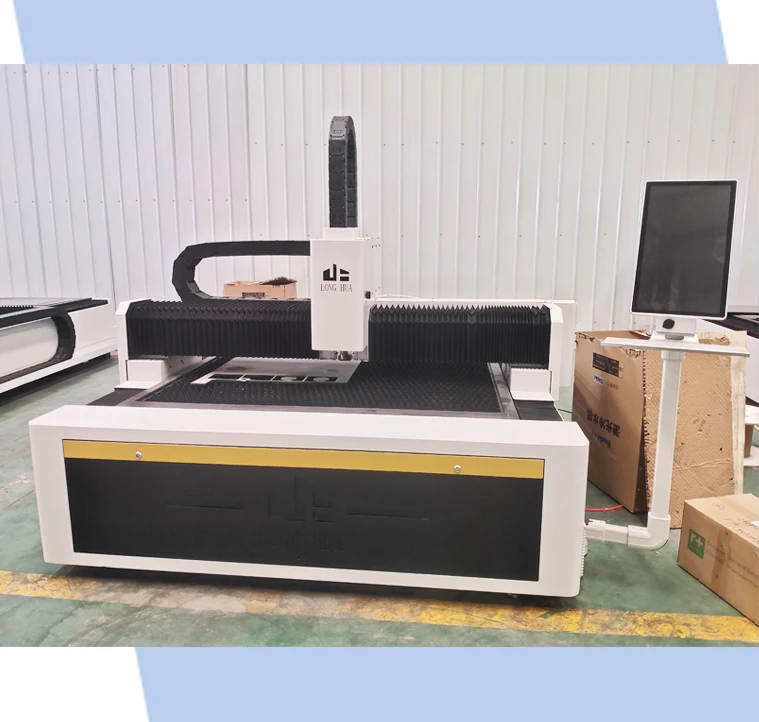

12 кВт машина для лазерной резки малого размера волоконный лазер 3000*1500 мм с подробным прайс листом

- Категория: >>>

- Поставщик: Anhui Runbang Heavy Industry Machinery Co. Ltd .Anhui .

Сохранить в закладки 1600104217129:

Описание и отзывы

Характеристики

CNC fiber laser cutting machine 1000W for Pipe & Metal Sheet

Advantages

1.Speed

When cutting mild steel, stainless steel, and aluminum plate, fiber laser cutting machine of equal power is 2-3 times faster than CO2 laser with smooth cutting .

2.cost

The maintenance cost of CO2 laser cutting machine is very high. Not only front lens and back lens are expensive, but also the working life of turbine bearings.

At the same time CO2 laser cutting machine photoelectric conversion rate is only 8% to 10%, and it consumes too much gas when cutting. But fiber laser cutting machine photoelectric conversion rate can reach 30%, which is more economic.

3.maintenance

We know that CO2 laser cutting machine laser has complex structure, inconvenient maintenance and high operation requirements. But the CNC fiber laser cutting machine has simpler maintenance. Besides,tolerance of dust, shocks , temperature and humidity in poor work environment.

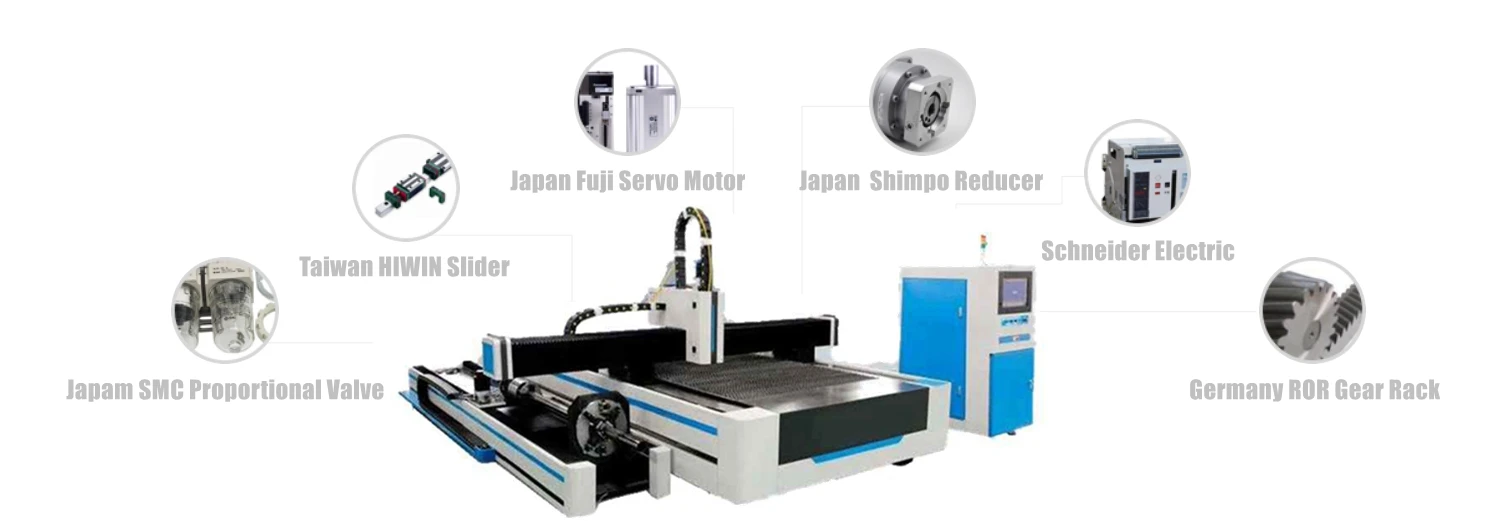

- 1. Laser generator Wuhan Raycus or Germany IPG

2. Laser cutting torch Raytools

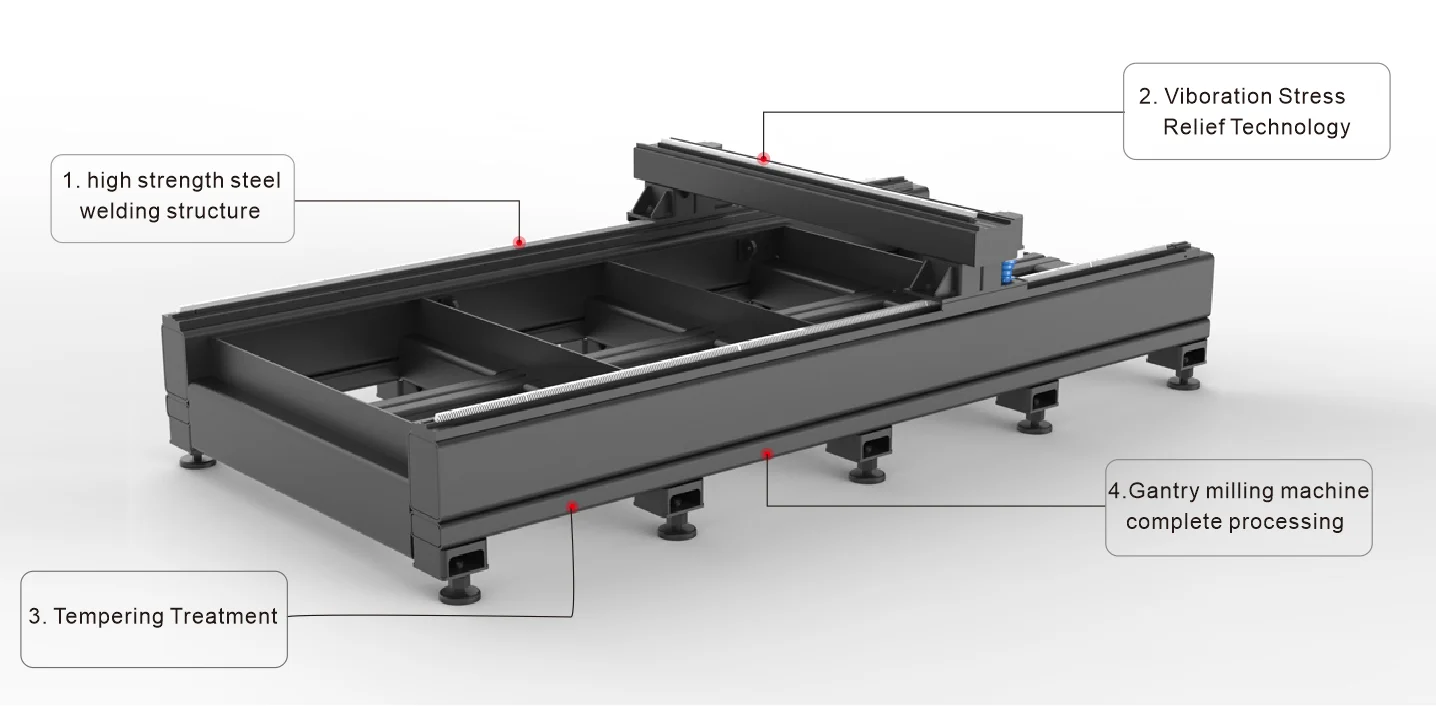

3. Cutting bed Steel plate welding

4. X, Y gear rack Germany ROR or Taiwan YYC

5. Guide rail Taiwan Hiwin

6. AC servo motor & driver Japan Fuji

7. Proportional valve Japan SMC

8. Reducer Japan SHIMPO

9. Gas circuit control Japan SMC

10. CNC system and software CYPCUT

11. Water cooling machine Guangzhou S&A

12. Dust Absorption set

2. Vacuum cleaner set

3. Voltage Regulator

4. Laser focusing lens

5. Laser protective windows

6. Laser ceramic rings

7. Laser Nozzles

Raycus Laser

China Wuhan Brand

IPG Laser

Germany Brand

Laser cutting torch

Automatic focus torch

Control Unit

CNC contol system & schneider electrics & laser

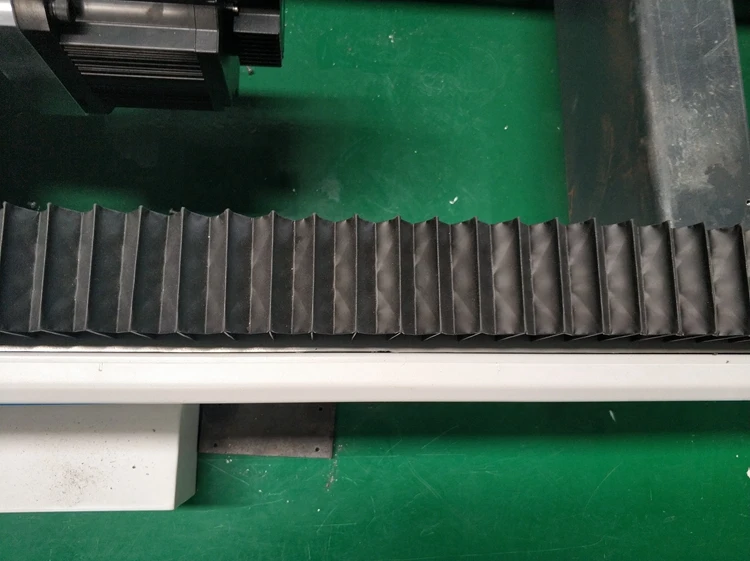

Guide rail gear rack protection cover

stainless steel plate and nylon flexible tube

ABS drag chain

air tube ,electric wire, laser fiber

YYC linear guide and gear rack

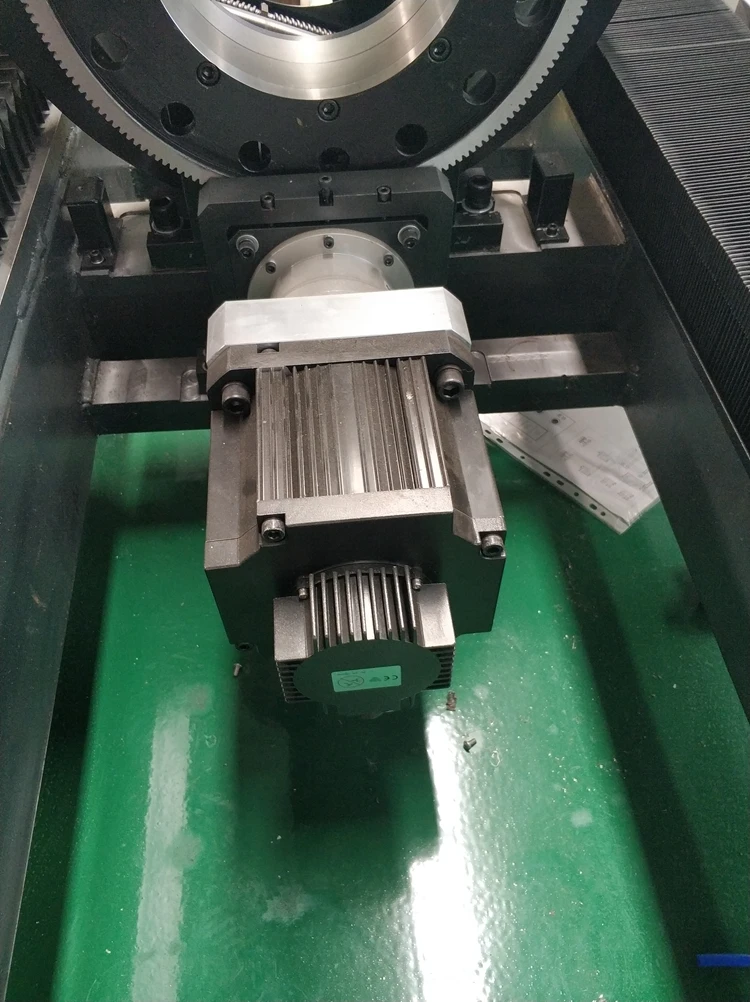

Gear and reducer

Water cooling device

S&A Brand

Remote Control

wireless control

Lubricants pump

Packing

The normal package is plastic film or pack it according to customers special request.

delivery

The goods are usually delivered by FCL or LCL to protect the machine.Shiping is the first choice.

4. Sales provide instructions and operation videos--Delivery--Dedicated after--Sales personnel Online service is available.

FAQ

Q: How to choose a laser cutting machine?

A: Please tell us the following information in detail:

- Material of plate:

-Max thickness:

-Max plate width:

-If possible: you can specify the model;

Q: Where is your factory? How can I get there?

A: You can fly to NanJing LuKou airport directly, we will pick you up in the airport. All our customers, both inland and abroad,

warmly welcome to visit us!

Q: How do you ensure quality in the factory?

A: Quality culture always attach great importance to quality control from the beginning to the end. Our factory has obtained

ISO, CE certification.

Q: How can I pay?

A: You can pay by T/T, Western Union, MoneyGram, Paypal; 30% deposit; pay off the 70% balance before shipment.

Q: How long to produce?

A: Delivery time:15-35 days.

Похожие товары

1500 Вт 2000 низкая цена волоконно-лазерная машина для резки 1530 20 мм лазерной металла в продаже

Горячая Распродажа лазерной резки металла lazer cut промышленное оборудование

Цена Японии лазерной резки производителей

LU DIAO 3 кВт нержавеющая сталь углеродистая для лазерной резки металла волоконно-лазерная машина цена

Нержавеющая листовая металлическая волоконная лазерная резка цена 2000 Вт

Китайский производитель волоконно-лазерная резка лазерная низкая цена лазерный резак по металлу

Экономичный станок для лазерной резки 6 кВт

Новые поступления

Новинки товаров от производителей по оптовым ценам