5L Blender equipment dental lab high speed vacuum emulsifying mixer

- Категория: >>>

- Поставщик: Wuxi YK Automation Technology Co. Ltd.

Сохранить в закладки 1600104336271:

Описание и отзывы

Характеристики

5L Dental lab high speed vacuum emulsifying mixer

In the manufacturing process of high-viscosity emulsions, especially creams, ointments, and emulsions, the most problem is usually the large particle size of the dispersed phase and the mixing of air into the product during agitation.

For the two major problems, our company developed the ZJR series vacuum homogenizing emulsifier unit , which also called as laboratory laboratory emulsifier, is complemented by homogenous agitator, central blade agitation and scraping wall mixing.

Structure introduction

(1)System

(2) Operation platform

(3) Tilting

(4) Heating & Thermal insulation

(5) Mixing & Ultra-highspeed homogenizing

(6) Connector

(7) Vacuum

(8) Lifting beam

(9) Intelligent operating system

(10) Lighting

(11) Pretreament pot

(12) Heating system

Reference data

Item | ZJR-10 |

Mixing vessel(L) | 10 |

Useful volume(L) | 8 |

Working pressure in the vessel(bar) | -1 to 2.5 |

Max. temperature in the vessel(℃) | 150 |

Stirring motor power (kw) | 0.25 |

Output speed (r/min) | 0-86 |

Homogenizing motor power(kw) | 1.1 |

Output speed (r/min) | 0-6000 |

Heating power(kw) | 2 |

Vacuum pump power(kw) | 0.25 |

Water vessel(L) | 7.8 |

Useful volume(L) | 6 |

Dispersion motor power(kw) | 0.025 |

Output speed(r/min) | 1200 |

Heating power(kw) | 1 |

Oil vessel(L) | 7.8 |

Useful volume(L) | 6 |

Dispersion motor power(kw) | 0.025 |

Output speed (r/min) | 1200 |

Heating power(kw) | 1 |

Dimensions(A*B*C,mm) | 1650*620*1100 |

Fectures

Small one makes big differences

The ultra-high speed precise Rotar/Stator system can stably operate at 6,000rpm and achieve the best homogenizing effect.

No dead angle scraper system

We have adopted the automatically bounced quick release design, which is convenient and easy to dismantle and clean.

Rotar/Stator can be changed

Different Rotar/Stator systems can be chosen according to the characteristics of materials, in order to achieve the best effect of making materials.

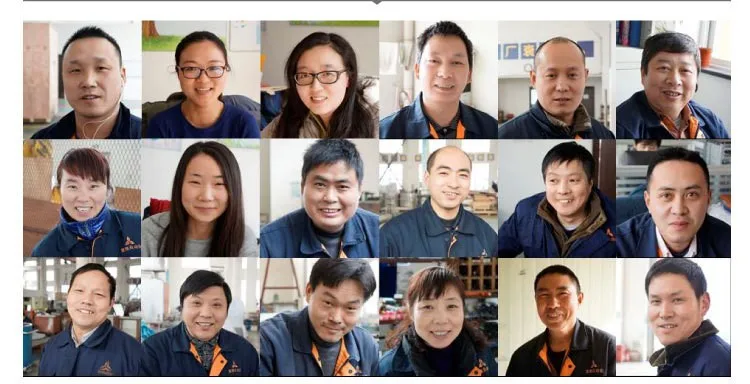

WUXI YK AUTOMATION TECHNOLOGY CO.,LTD

Office

Our Certification & Honor

Our market

Our supplies:

More than 85% of purchased parts come from top suppliers, such as ABB, SIEMENS...

Warranty time:

One year, from the date which the product is qualified commissioning. Any damage except the wrong operation during warranty period is repaired freely. But the travel and hotel expenses should be count on buyer.

Commissioning services:

The product's installation and commissioning at the demand side, our engineers will not leave there untill get your agreement.

Training services:

Our engineers will train your staff to operate it during the period of installation and commissioning, and they will not leave there until your staff can operate it properly and normally.

Maintenance services:

Any malfunction happened, once you enquiry us, we will reply you within 48 hours except the special reasons.

Lifelong services:

We provide lifelong services for all the products we sold out, and supply the spare parts with discount price.

Certificate services:

We can provide related certificates to customers freely according to the request of customers.

Inspection services:

You can ask the third part inspection company or your inspector to inspect the products before shipment.

The file:

The Manual Specification, report of the material which used to the equipment and others documents related to the GMP authentication information will be provided by us.

1. Why your machine similar with other supplier?

We are an overseas-funded enterprise. We are manufacturer and had been in this industry for more than 17 years, with more than 9 years export experience. We design machines by ourselves with advanced technology. Appearance just a part of machine, Service and quality is more important than it.

2. I'm new in our industry, but I'm planning to setup a factory, What can I do?

We can suggest customer the most suitable machine according to their formula, Raw material. Manufacturing- Installation- Training- Maintenance- Technical Support. We can introduce you supplier of raw material, bottles, labels etc. We could take you to our customer's factory to learn how they produce. We could customize machines according to your real need, We could send our engineer to your factory to install machines and train your worker of Operation and maintenance. Any more requests. Just let us know.

3.Why do you choose us?

Select spare parts with high quality and well-known brands only.

We are approved by ISO, CE, GS and etc.

One year warranty; perfect after-sales service for spare parts

Best prices with good quality and reliable performance

Easy maintenance

Our logo or OEM

4.What kind of machines can you supply to customer?

We could offer various kinds of machines and whole production line.

(1) Cream, paste Products,

In cosmetic industry: face cream, body cream etc

In food industry industry: sauce, ketchup etc

In chemical industry:welding paste,ink, paint etc.

Production line for them: RO water treatment etc

(2) Liquid products

Shampoo, lotion, liquid soap, detergent,juice,solution etc.

Production line for them: RO water treatment - liquid wash mixer etc

(3) Make-up products:

Lipstick, lip gloss, nail polish, marscara etc

Machines for them: homogenizer mixer, colliod mill, lipstick filling machine, frezzing machine etc

(4) Adhesive products:

Instant glue, AB glue, silica gel, anaerobic adhesive,silicon, sealing etc.

Machines for them: double planet mixer, ribbon blender, tube filling and sealing machine etc

We Warmly Welcome Your Visiting

Похожие товары

Летняя Милая одежда для сна, шелковая одежда для сна, Pjs Piyama, недорогие пижамные шорты из 2 частей, Атласный пижамный комплект, домашняя одежда для женщин

Сверхмощный колесный погрузчик 950E хорошего качества с деревянными бревна

Уличная светодиодная линейная лампа smd5050 с изменением цвета IP65, светодиодная цифровая трубка для видео dmx rgb

Горячая Распродажа от производителя, oem паста для мытья посуды, жидкое мыло, машина для смешивания шампуня для рук

Высококачественное натуральное бамбуковое половинное бамбуковое ограждение, естественное свернутое полностью новое бамбуковое ограждение для конфиденциальности в саду

Универсальный Длинный емкостный сенсорный Стилус для смартфонов, сотовых телефонов, планшетов, ручек с пылезащитными заглушками

Винтажная ручная работа, марокканская Турецкая напольная Подушка kilim, напольная подушка, пуфф, оптовая продажа C11680

Новые поступления

Новинки товаров от производителей по оптовым ценам