Лучшая заводская цена полностью автоматизированный светодиодный ЖК телевизор производственная линия

- Категория: >>>

- Поставщик: Shenzhen Carst Technology Co. Ltd.

Сохранить в закладки 1600111587168:

Описание и отзывы

Характеристики

Project design

We are a professional manufacturer of all kinds of customized production line equipment for customers, if you have this idea,please feel free to consult us, we will provide you with the best service and the most appropriate scheme.

Products Description

The overall layout includes assembly, testing, repair, and packaging lines.

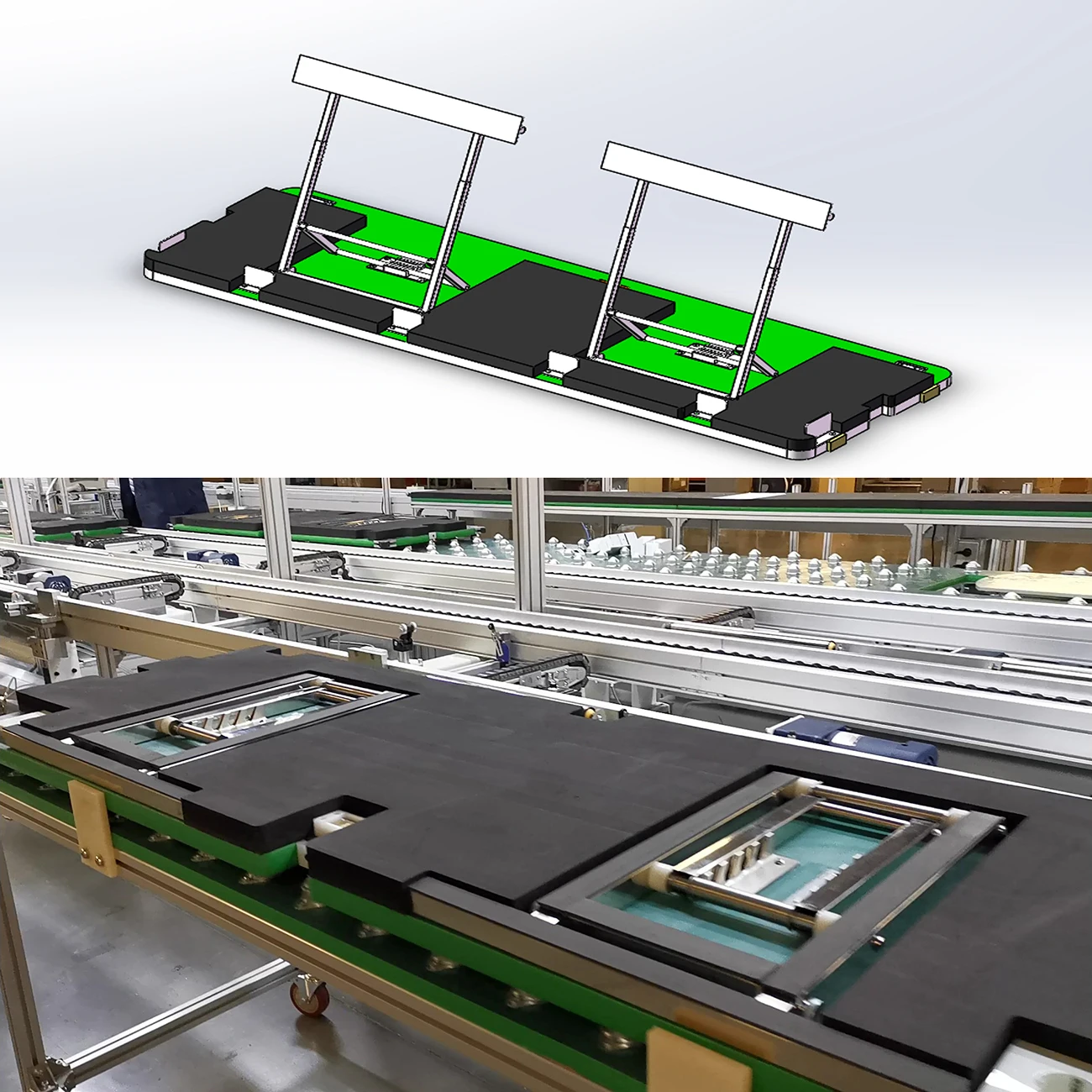

LED TV Assembly Roller transmission Production Line |

1. The Roller width is 1000mm, and adopts 65-24 TV production . |

2. Can be equipped with different tools according to production needs. |

3. The top and bottom of the line body are equipped with 3/4 air pipes, and one quick joint is prepared for per meter. |

4. Each station has a contral button to contral its operation and stopping. |

Testing line |

Contains multiple test items, high voltage test, TV signal test, WiFi test, U disk test, image test, sound test, silent test,Bluetooth test etc. |

Aging line |

Perform aging tests on the TV to reduce the failure rate of the TV. |

Tooling board |

Can be customized according to the needs of actual production suitable for any size TV tooling board. |

Packing Line |

After the TV is completed, put it in a carton, seal it and pack it.Contains roller conveyor lines, taping machine and strapping machine. |

E-SOP Standard Operating Procedure System (The electronic screen displays the SOP dynamically to guide employees' operations more clearly. Greener and easier to operate.)

1. Perfect authority management function to ensure the safety control of SOP files, clear rights and responsibilities, and directly switch the software interface display drawings.

2. A variety of presentation methods, work instructions can be video, PDF files, Word files, Excel tables, PPT slides, pictures.

3. Template customization, quick change line.

4. Preview the display content of the station in time to prevent allocation errors.

5. Support the automatic page turning and manual page turning mode of each station.

6. Notification information can be issued for workshops, production lines and work stations, and the station will automatically display.

7. Support file bulk upload, greatly simplify the operation.

2. A variety of presentation methods, work instructions can be video, PDF files, Word files, Excel tables, PPT slides, pictures.

3. Template customization, quick change line.

4. Preview the display content of the station in time to prevent allocation errors.

5. Support the automatic page turning and manual page turning mode of each station.

6. Notification information can be issued for workshops, production lines and work stations, and the station will automatically display.

7. Support file bulk upload, greatly simplify the operation.

Shipping and Packing Scenes

Company Environment

Customes pictures

Part Customers

FAQ

You Ask: |

1:I want to start this business, but I don’t have any experience,how can you help me? A:We have been in the equipment industry for more than ten years and have rich experience in building LED/TV/Mobile Phone/Power Supply/Refrigerator compressor factories.We can provide one-stop support and services from factory construction to raw material procurement to related equipment procurement to factory production. |

2:I want to start this business, but I don’t have enough funds,how can you help me? A:First of all, the equipment with higher automation is not necessarily suitable for you, but the price is definitely expensive.We will provide the machine solution that best fits your current capacity and budget. Manual or semi-automatic machines, coupled with good production management, can also produce good products. |

3:I have been in this business for several years, but the production capacity has been very low,how can you help me? A:How efficient are your employees? Is your machine stable? How do you test and age products? How is the market feedback on your product quality? |

4:My factory has been opened and the equipment has been bought. Can you give me any suggestions for upgrading my company? A:Please send me your current production equipment pictures and on-site production videos.Manual operations can be upgraded to flow belt line operations, manual machines can be upgraded to semi-automatic or fully automatic machines, and single station machines can be upgraded to multi-station machines. |

5:I bought your machine, but I can’t install and operate it,how can you help me? A:All equipments enclosed “Installation and Operation Manual”.You can take your samples to our company for production demonstration, training how to install, operate and maintain the equipment.And we also can provide engineers to your factory for installation and training service. |

6:Although your engineers have completed the installation and training in our company, how can I slove it if the problems of equipment appears again after returning to China? A:First,we can provide online WeChat and video remote instruction,remotely modify or upgrade programs,and ship the spare parts by Air.After this series of operations, the problem has not been resolved, we will send engineers to your company to provide on-site services. |

We Ask: |

1:What’s the products you are producing or plan to producing? 2:What’s your production capacity for 8 hours? 3:What’s the detailed information of your products? 4:How do you plan your factory,that’s also mean what’s the machine you plan to purchase? 5:What are the issues in your factory planning process? 6:When will you plan to start the project? |

Contact Information

Charlie Yang(杨春林)

Shenzhen Carst Technology Co.,Ltd

Mob:+86 15013801065 Email:charlieyang@carstker.com

WeChat/Whatsapp: +86 15013801065

QQ:1090296323 LinkedIn:Charlie Yang

Web:www.carstker.com

ADD:No 201, Building A, Nandong Third Industrial Zone, Shajing Street, Baoan District, Shenzhen, China

Shenzhen Carst Technology Co.,Ltd

Mob:+86 15013801065 Email:charlieyang@carstker.com

WeChat/Whatsapp: +86 15013801065

QQ:1090296323 LinkedIn:Charlie Yang

Web:www.carstker.com

ADD:No 201, Building A, Nandong Third Industrial Zone, Shajing Street, Baoan District, Shenzhen, China

Похожие товары

Войлок для резки

Наклонный передвижной пластиковый охлаждающий ленточный конвейер из нержавеющей стали инструмент для

Сделанная в Дунгуань изогнутая ленточная конвейерная система с

1 500,00 $ - 2 300,00 $

CW завод небольшой цементный сухой раствор гранулированная мука цена без вала горизонтальный винтовой Конвейерный

2 000,00 $

Новейший и самый лучший разгрузчик из нержавеющей стали является

1 000,00 $

Корма для скота шеврон наклонная боковая стенка шеврон грубый резиновый конвейер

10,00 $ - 20,00 $

Белый пищевой ПВХ конвейер

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $