Видео! Фабричная высокоточная Миниатюрная пластиковая коробка/пресс форма для литья под давлением

- Категория: >>>

- Поставщик: Yueqing Nationhunter Imp.&Exp. Co. Ltd.Yueqing Ltd.

Сохранить в закладки 1600116319937:

Описание и отзывы

Характеристики

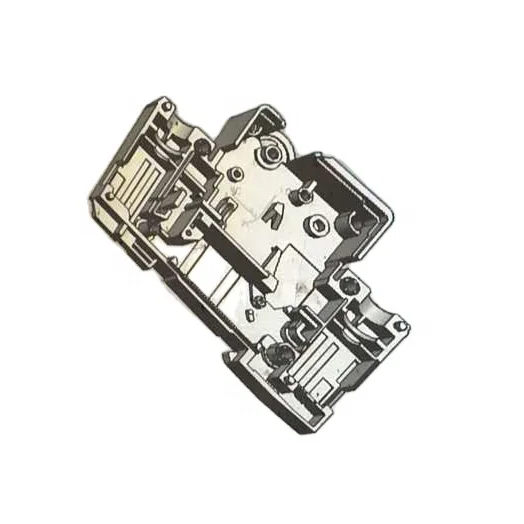

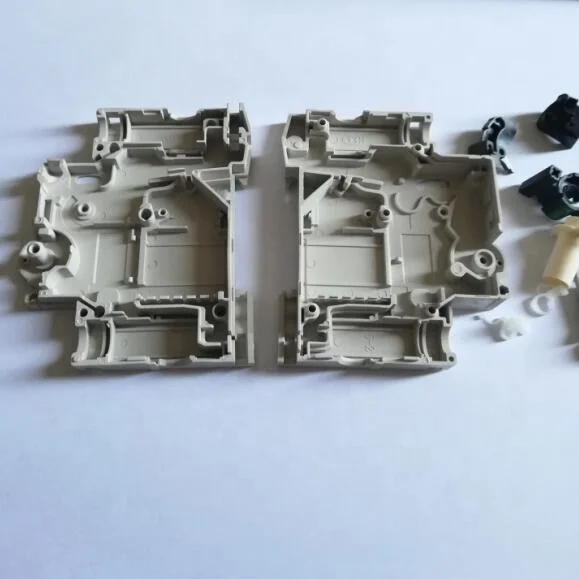

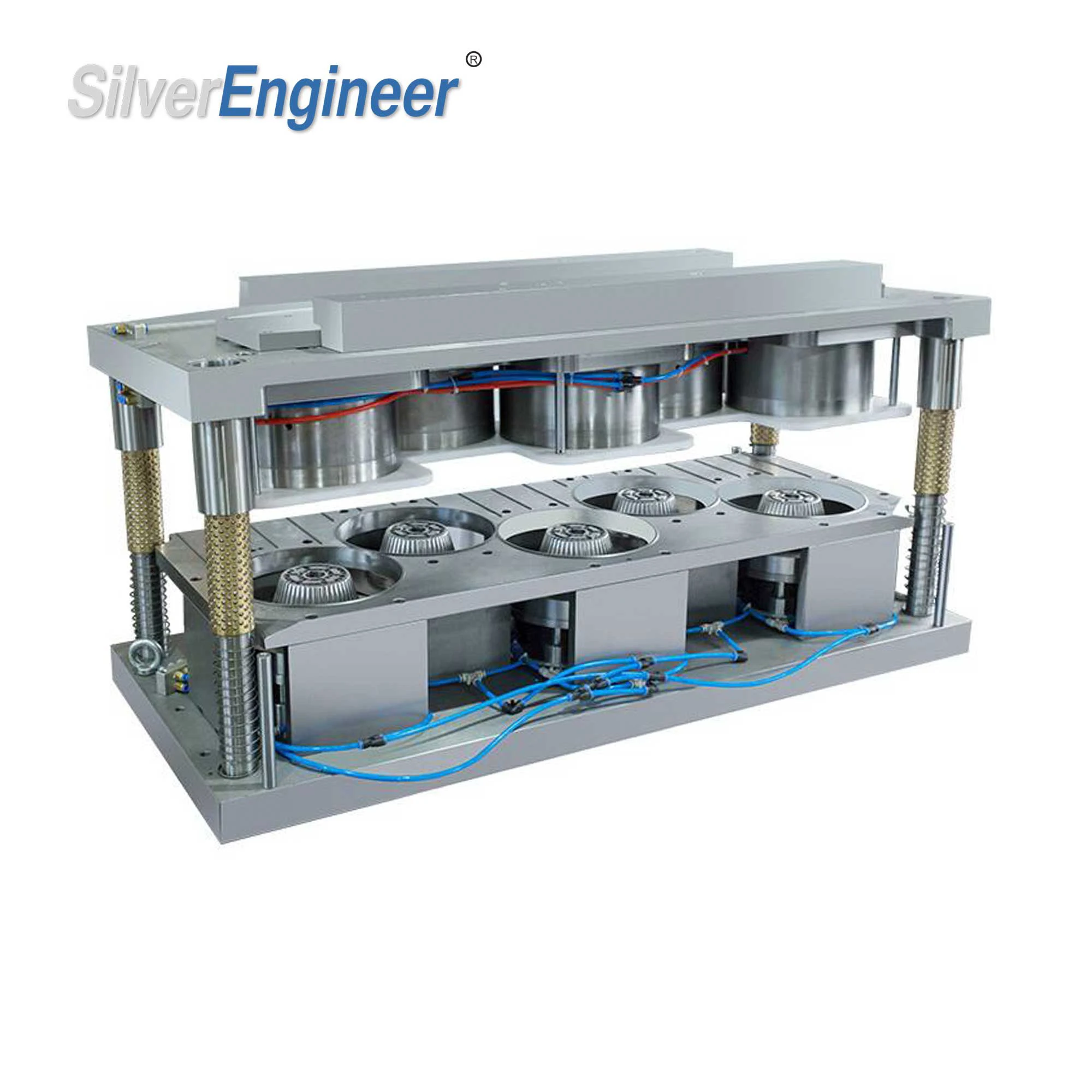

We are professional in making high precision electronic/electric plastic parts injection mould and molding the finished parts for customers.

Warning: All of the moulds and samples pictures below are reserved by my company.I will claim compensation if anybody stealing pictures from here.

We started exporting our moulds to more than 100 countries since 2004.

Plastic | PA66+GFR |

Cavity & Core | SKD61,SKD11,2316,S136 |

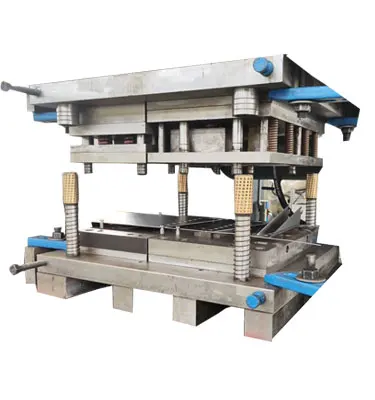

Mold base | LKM or others brands standard mold base |

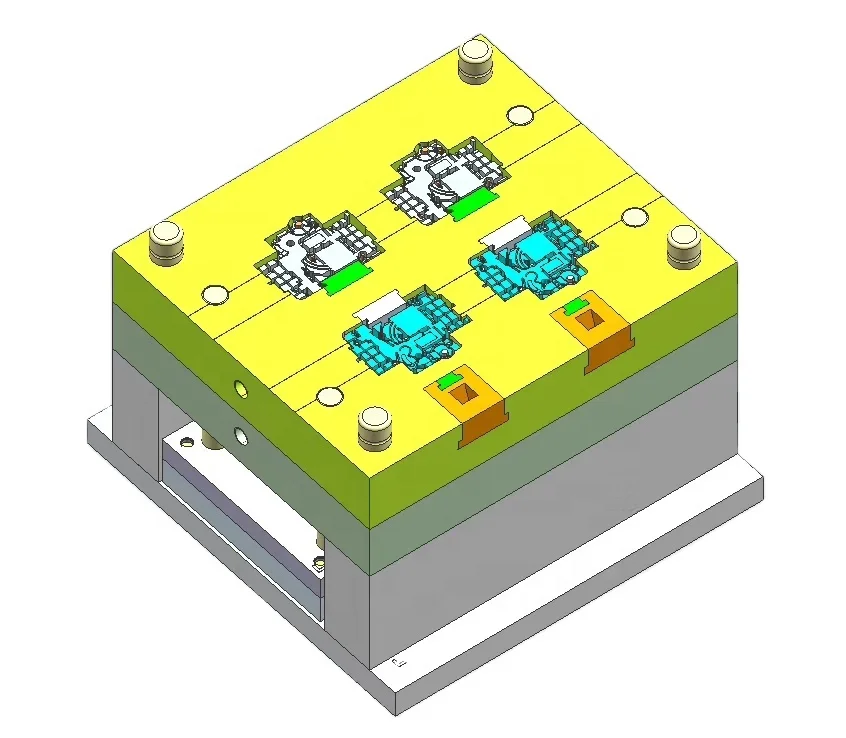

Nos of Cavity | According to customers’ requirements |

Treatment of hardening | Vacuum hardening, HRC48-52 |

Mould Accessories | DME/HASCO Standard |

Cooling | Perfect water cooling system |

Surface finish | Refer to sample or customers’ requirements |

Molding life | 1 000 000-3 000 000 cycles |

Runner | Cold or Hot |

Delivery time | 35-60 days |

Packing | Plywood case |

We are long-term committed to develop precision electronic&electrical plastic parts mould,precision automotive parts mould,precision instruments&meters mould,precision cell phone accessories mould,zinc and aluminum die castings. We supplied moulds to many famous companies,such as Bosche,Valeo,Sangsung,ABB,Siemens Wedio,Schneider,etc.

We have rich experience in developping precision moulds and powerful Pre analysis capability.We can help to improve the parts structure and design before mould production in order to reduce the possible modifications after finish moulds.We use mold CAE analysis MOLDFLOW for Forming simulation analysis to find the defects on desiging and revise it on time.

For mold processing,we can ensure single mold component processing accuracy in 0.003mm,and the accuracy can be 0.005mm for multi cavities,the accuracy of alignment for parts parting line can be 0.01mm.

Our fastest mold delivery time can be 13-15 days, and the delivery time can be 30-45 days for more than 20 sets molds.

Request for quotation?

1. Sample photo with size or 2D/3D drawing

2. Cavity NO.

3. Runner type, cold or hot

4. Mould material, P20, 718, 2311,2344,2738,H13,SKD61,S136,2316,an so on.

5. Your Injection molding machine specification

Our advantage

1. The most Experienced and professional boss who can answer all of your questions related to moulds in english.He knows everything about mould and well known with the professions for every set mould.

2. Good quality and long life mould.

3. The most reasonable price.

4. Delivery on time

5. Send project schedule report and pictures to buyer to updaing the progress of mould making.

6. Our international sales team work 14 hours per day to serve you

Похожие товары

ПЭТ Преформа пластиковая литьевая форма

Высококачественный пищевой одноразовый контейнер из алюминиевой фольги форма от серебряного инженера

RZLH-MJ высокоизносостойкой пищевой упаковки контейнеры из алюминиевой фольги автоматизированная алюминиевая контейнерная форма

Высокая точность однополостная многополостная алюминиевая фольга контейнер форма для фольги

Изготовитель под заказ штампованная алюминиевая форма фольга контейнер

Автоматическая одноразовая алюминиевая фольга лоток тарелки фольги контейнер делая машину

Автоматическое производство высокоскоростной многополостной алюминиевой фольги пищевой контейнер плесень

Новые поступления

Новинки товаров от производителей по оптовым ценам