Гидравлический цилиндр из фенольной ткани износостойкое кольцо направляющее PTFE направляющая полоса

- Категория: >>>

- Поставщик: Guangdong Nanfang Nylon Products Co. Ltd.

Сохранить в закладки 1600120766724:

Описание и отзывы

Характеристики

Guangdong Nanfang Nylon Products Co. Ltd. , established in 1988 , is a professional production of "Engineering plastics accessories" high tech enterprises . Company have a complete set of imported production equipment and numerical control processing equipments .

Company main products are : UHMW-PE , MC Nylon , PA6, POM , HDPE , ABS , PU , PC , PVC , PP ,PET, PBT , Acrylic , PEEK PPS, PTFE , PVDF , PAI , PEI , PSU , PI , PBI, Antistatic product series . Copnay strictly enforce ISO9001 international quality certification system.

| Product Information | |

| Product Name wear ring | Hydraulic Cylinder Seals wear ring guide ring seal hydraulic seal |

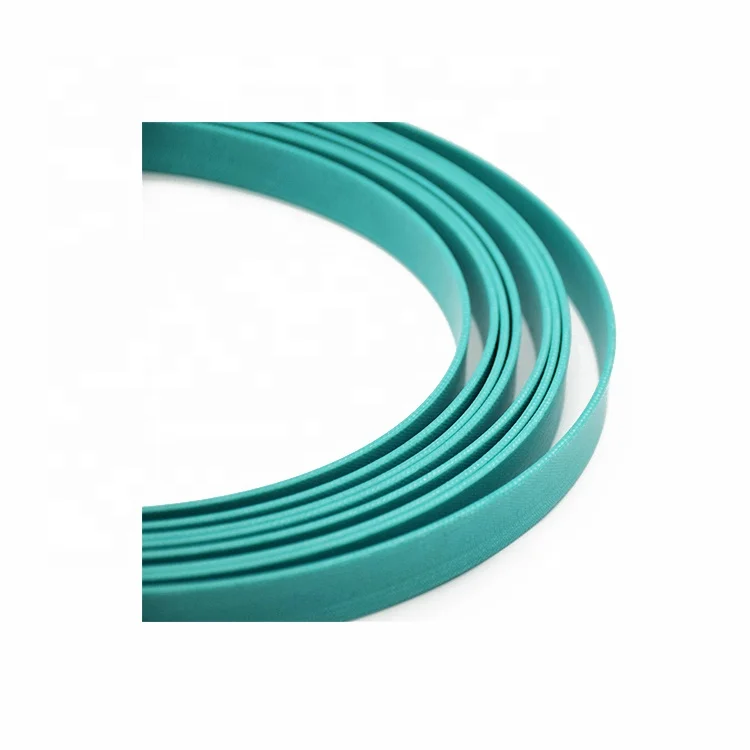

| Type guide ring guide ring | Wear Ring / Guide Ring / Guide Strip fabric wear ring |

| Feature wear ring guide | Wear Resistance ptfe guide ring seals phenolic wear ring guide ring strip |

| Size wear ring guide ring | 50*40*10mm wear strip fabric wear ring guide ring seal |

| Material guide strip ring | PTFE hydraulic seal wear ring guide ring ptft guide ring |

| Application wear ring | Hydraulic Cylinder Piston & Rod fabric wear ring guide ring strip |

| Temperature guide ring | -55℃-+120℃ phenolic fabric wear ring guide ring ptfe guide strip |

| Pressure wear ring | ≤ 35 MPa wr hyfraulic seal wr seal hydarulic rod seal wear ring guide ring |

Feature

Feature

1. Good dimensional stability

2. Good sliding performance and dry running characteristics

3. Excellent wear resistance

application

Construction machinery and equipment, packaging machinery and equipment, logistics and transportation equipment, mining machinery and equipment, heavy hydraulic equipment

Guangdong Nanfang Nylon Products Co. Ltd. is a polymer parts producer based in Foshan, China, found in1988.With decades of experience dealing with polymer material, every aspect of producing a part is considered.

Guangdong Nanfang Nylon Products Co. Ltd. is a polymer parts producer based in Foshan, China, found in1988.With decades of experience dealing with polymer material, every aspect of producing a part is considered.

The company is committed to manufacture the highest class parts possible, striving to not only meet the requirements of the print, but also making parts that are clean with minimal tooling marks.

Within the factory, the production is run by four workshops, machinery processing shop, injection molding shop, mold shop and material synthesis shop.

As the biggest workshop in the factory, the machinery processing shop has a full set of equipment, such as: lathe, mill,sawing machine, grinding machine, water-jet cutting machine and HAAS CNC from the US. Almost all processes can be done in the workshop with well control.

As the biggest workshop in the factory, the machinery processing shop has a full set of equipment, such as: lathe, mill,sawing machine, grinding machine, water-jet cutting machine and HAAS CNC from the US. Almost all processes can be done in the workshop with well control.

For high volume production, injection molding is the best option. The biggest injection molding machine in shop, has aclamping force of 560 tons, with maximum injection weight of 2 kilograms.

Departing from the machinery processing shop, mold shop is mainly responsible for the production and maintenance of the mold. Offering the strongest backup to the injection molding shop.Full in-house quality check devices can guarantee the parts are built to our customer's specification.

Похожие товары

Износостойкие кольца для цилиндра экскаватора 9,7x2,5, Направляющая лента H506

Гидравлическое износостойкое кольцо из фторопласта, Направляющая лента из фенольной ткани, направляющая кольцевая лента

Бирюзовая фенольная направляющая лента

2021 SL серия металлический Собранный спортивный трофей SL070

Крытый баскетбольный игровой автомат для стрельбы аркадный мяч dunk игровой автомат для продажи

Индукционный подшипниковый нагреватель типа NC DKQ- IV

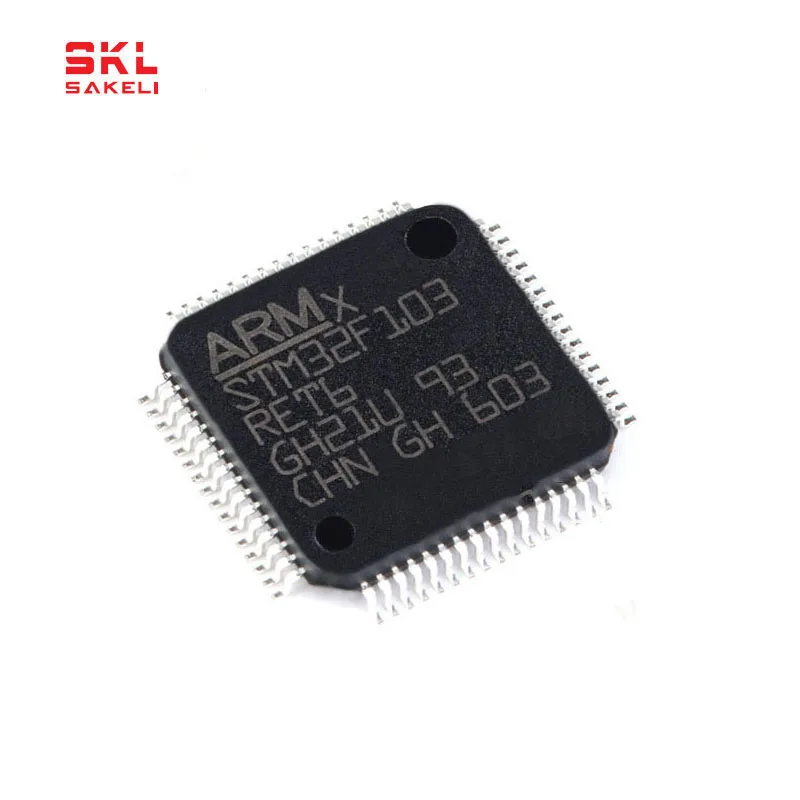

Онлайн Электронные компоненты Stm32f103ret6, интегральные схемы, новые оригинальные Lqfp64 Mcu Stm32f103ret6

Новые поступления

Новинки товаров от производителей по оптовым ценам