Высокоскоростные высокоточные рулонные жалюзи для лазерной резки ткани с конвейером

- Категория: >>>

- Поставщик: Wuhan Golden Laser Co. Ltd.

Сохранить в закладки 1600134167949:

Описание и отзывы

Характеристики

NOTE: Different configurations have different prices. The price on Alibaba is NOT real price, please contact us to get the latest quotation. Thank you.;-)

Product Description

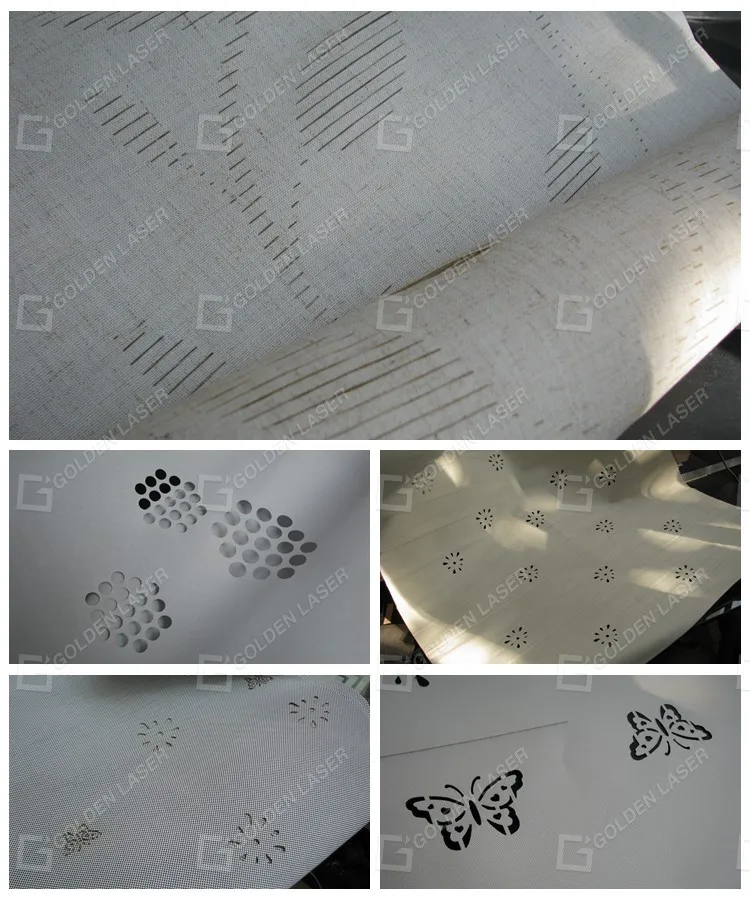

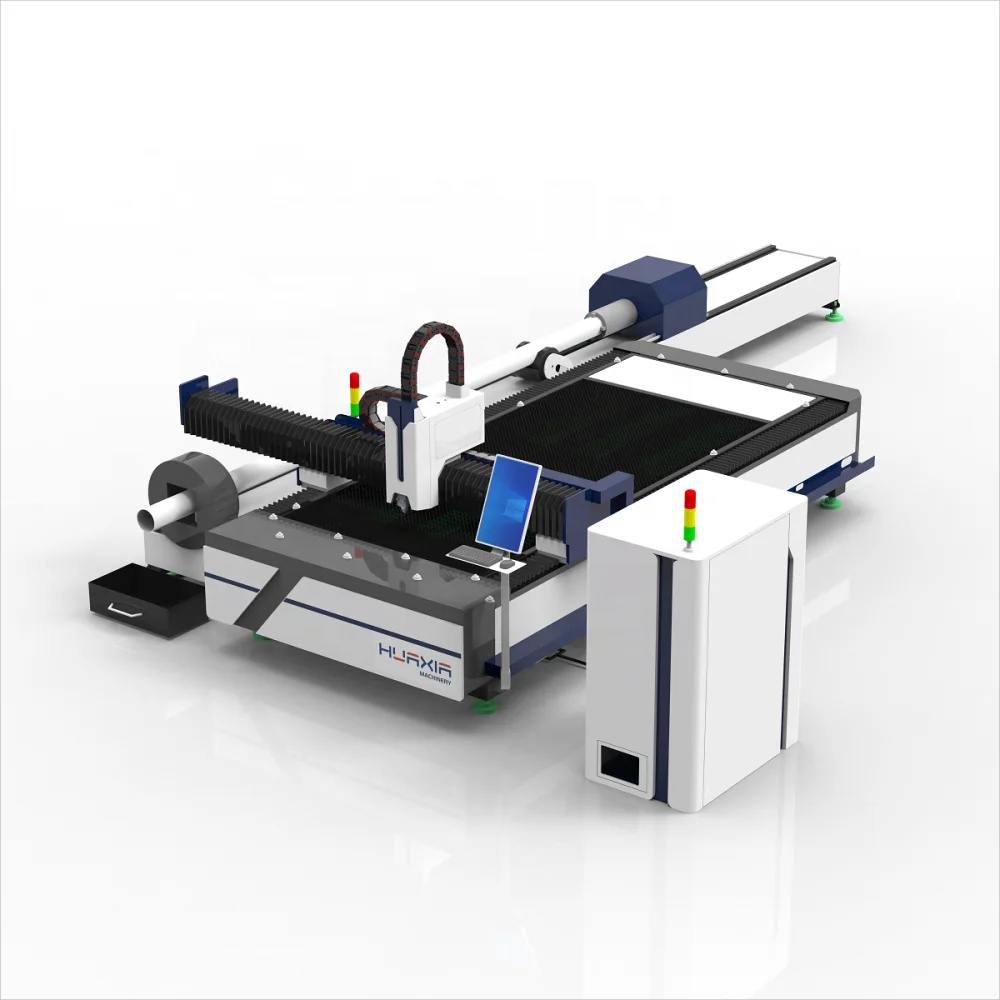

Cloth Laser Cutting Machine

__

High performance Gear and Rack Driven CO2 Flatbed Laser Cutting System for textiles processing features high speed, high precision and highly automated.

The gear & rack driven laser machine is upgraded from the basic belt driven version. The basic belt driven system has its limitation when running with high power laser tube, whereas the gear & rack driven version is strong enough to undertake the high power laser tube. The CO2 laser cutting machine can be equipped with high power laser tube up to 1,000W and flying optics to perform with super high acceleration speed and cutting speed.

The gear & rack driven laser machine is upgraded from the basic belt driven version. The basic belt driven system has its limitation when running with high power laser tube, whereas the gear & rack driven version is strong enough to undertake the high power laser tube. The CO2 laser cutting machine can be equipped with high power laser tube up to 1,000W and flying optics to perform with super high acceleration speed and cutting speed.

Now it's time for you to consider using a laser solution and giving your company an edge over the competition.

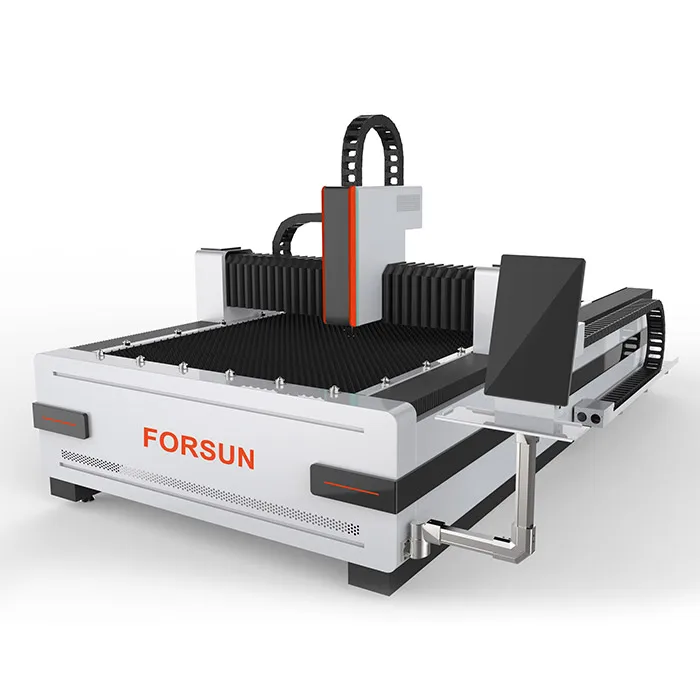

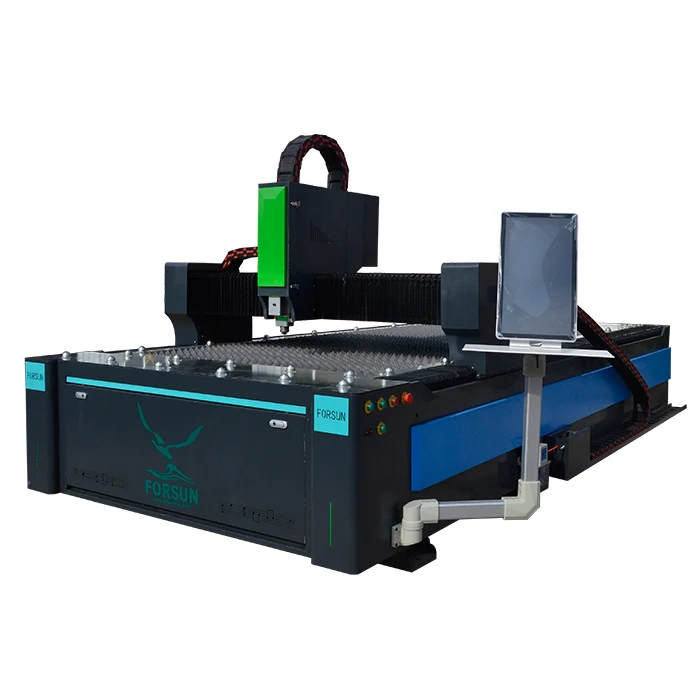

Machine Pics

__

Specification

JYCCJG-160300LD Technical Parameters | ||

Laser type | CO2 laser | |

Laser power | 150w, 300w | |

Working area (W × L) | 1600mm×3000mm (63”×118”) | |

Max. material width | 1600mm (63”) | |

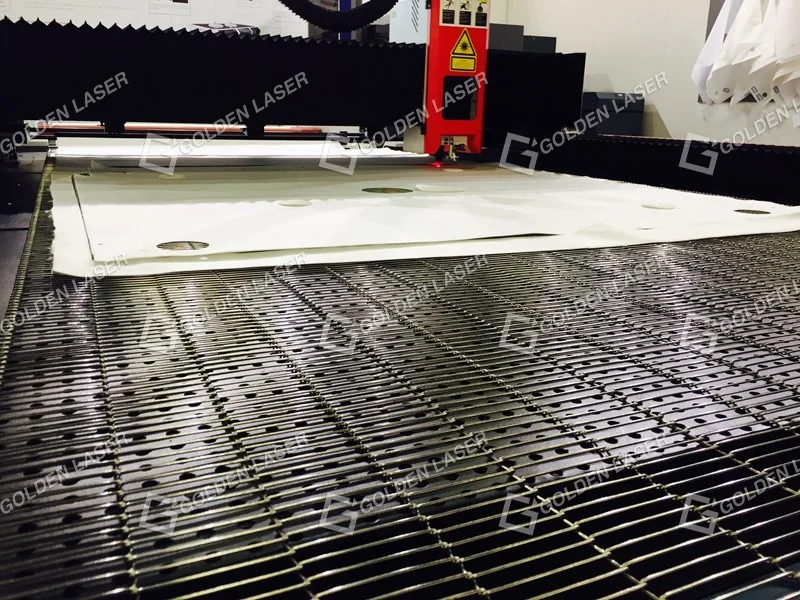

Working table | Vacuum conveyor working table | |

Cutting speed | 0 ~ 1200mm/s | |

Acceleration | 8000mm/s2 | |

Repositioning accuracy | ≤0.05mm | |

Motion system | Servo motor, Gear and rack driven | |

Power supply | AC220V±5% 50/60Hz | |

Graphics format supported | PLT, DXF, AI, DST, BMP | |

Features

__

* The CO2 flatbed laser cutter is designed for wide textile rolls and soft materials automatically and continuously cutting. Driven by gear and rack with servo motor control, the laser cutting machine offers high precision and cut quality at the highest cutting speed and acceleration. The laser cutter machine is available with a laser power from 150 watt to 800 watt. The large format cutting table can be applied to most of the typical fabric rolls.

* With the option of the auto-feeder, roll materials are fed to the cutting table directly and cut continuously. The machine is with vacuum suction underneath the conveyor working table, which ensures the materials to be flat on the table. Different vision systems can be equipped with this laser machine for diversified application such as dye sublimation printed textile cutting. Mark pen or ink-jet print head option is available to make marks for sewing or other purpose.

* High precision grade gear and rack driving system. With high-powered CO2 laser tube, cutting speed is up to 1200mm/s, acceleration is up to 8,000mm/s2, and can maintain long-term stability.

Configurations

__

* Japanese Yaskawa servo motor - Ensure maximum precision, reliability, and performance.

* Vacuum conveyor working table - The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible.

In addition, it has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

* Working areas can be customized - 1600mm×3000mm (63”×118”), 2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4in)

* The CO2 flatbed laser cutter is designed for wide textile rolls and soft materials automatically and continuously cutting. Driven by gear and rack with servo motor control, the laser cutting machine offers high precision and cut quality at the highest cutting speed and acceleration. The laser cutter machine is available with a laser power from 150 watt to 800 watt. The large format cutting table can be applied to most of the typical fabric rolls.

* With the option of the auto-feeder, roll materials are fed to the cutting table directly and cut continuously. The machine is with vacuum suction underneath the conveyor working table, which ensures the materials to be flat on the table. Different vision systems can be equipped with this laser machine for diversified application such as dye sublimation printed textile cutting. Mark pen or ink-jet print head option is available to make marks for sewing or other purpose.

* High precision grade gear and rack driving system. With high-powered CO2 laser tube, cutting speed is up to 1200mm/s, acceleration is up to 8,000mm/s2, and can maintain long-term stability.

Configurations

__

* Japanese Yaskawa servo motor - Ensure maximum precision, reliability, and performance.

* Vacuum conveyor working table - The machine feeds the material automatically in a continuous cycle in synchronism with the conveyor bed eliminating downtime completely to achieve the maximum productivity possible.

In addition, it has the function of negative pressure adsorption to ensure the flatness of the fabric during laser cutting.

* Working areas can be customized - 1600mm×3000mm (63”×118”), 2300mm×2300mm (90.5 inch×90.5 inch), 2500mm×3000mm (98.4in×118in), 3000mm×3000mm (118in×118in), Or optional. The largest working area is up to 3200mm×12000mm (126in×472.4in)

Options

Optional extras simplify the processing production and increase the possibilities

__

1. Safety Protective Cover -

Making the processing safer and reducing fume and dust that may be generated during processing. It is available with Full Enclosed option to meet class 1 laser product safety protection.

2. Auto Feeder -

It is a feeding unit which runs synchronous with the laser cutter. the feeder will transfer the roll materials to the cutting table after you put the rolls on the feeder. You can set the different feeding speeds according to the main machine speed. The feeder has the sensor to ensure accurate positioning of the material. The feeder can be equipped with different shaft diameters for different rolls. The different pneumatic roller will be used for the textiles with different tension, thickness... This unit helps you to realize a completely automated cutting process.

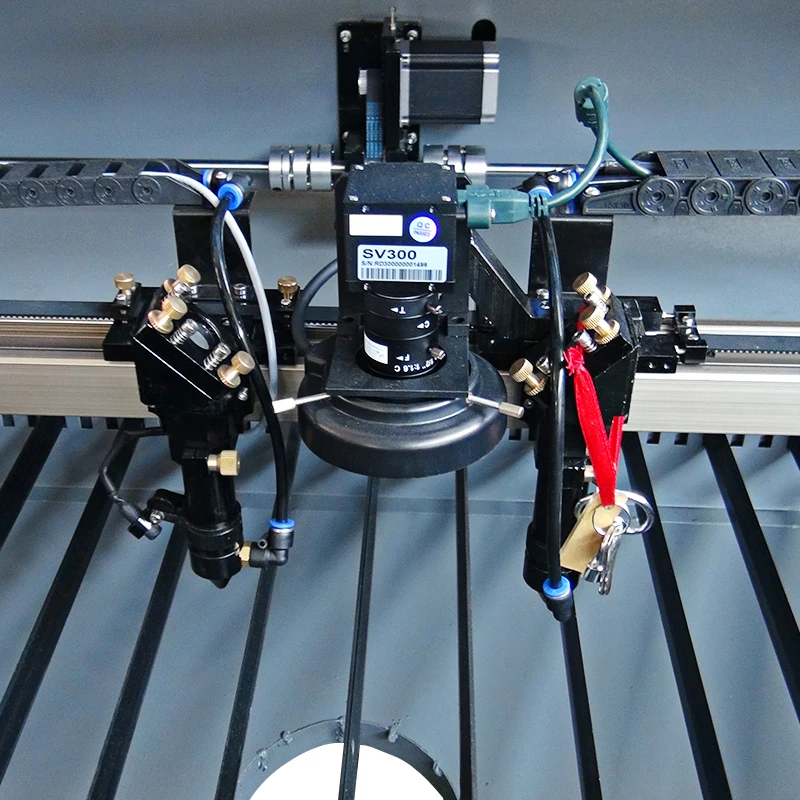

3. Optical Recognition System (CCD Camera) -

The vision system is an important option when you want to cut the contours. No matter for printing contour or embroidery contour, you will need this device to read the contour or special data for positioning and cutting. Contour scanning and marks scanning are suitable for different application. We offer different vision options for different applications.

4. Marking Modules -

1) Mark pen - For most of the laser cutting pieces, especially for textiles, it has to be sewn after cutting. You can use the mark pen to make the marks on the cutting piece to help the workers for easy sewing. You can also use the mark pen to make some special marks on the cutting piece such as the serial number of the product, the size of the product, the manufacture date of the product and etc...You can choose different color mark pens according to the color of your materials.

2) Ink-jet printing - Comparing with the “mark pen” the ink-jet printing technology is a non-touch process, so it can be used for many more different types of materials. And there are different inks for an option such as volatile ink and non-volatile ink, so you can use it in different industries.

5. Red Dot Pointer - Laser Beam Tracing System

The red dot pointer helps as a reference to check where the laser beam will land on to your material by tracing a simulation of your design without activating the laser. As well as your starting point.

6. Automatic Sorting System -

Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

1. Safety Protective Cover -

Making the processing safer and reducing fume and dust that may be generated during processing. It is available with Full Enclosed option to meet class 1 laser product safety protection.

2. Auto Feeder -

It is a feeding unit which runs synchronous with the laser cutter. the feeder will transfer the roll materials to the cutting table after you put the rolls on the feeder. You can set the different feeding speeds according to the main machine speed. The feeder has the sensor to ensure accurate positioning of the material. The feeder can be equipped with different shaft diameters for different rolls. The different pneumatic roller will be used for the textiles with different tension, thickness... This unit helps you to realize a completely automated cutting process.

3. Optical Recognition System (CCD Camera) -

The vision system is an important option when you want to cut the contours. No matter for printing contour or embroidery contour, you will need this device to read the contour or special data for positioning and cutting. Contour scanning and marks scanning are suitable for different application. We offer different vision options for different applications.

4. Marking Modules -

1) Mark pen - For most of the laser cutting pieces, especially for textiles, it has to be sewn after cutting. You can use the mark pen to make the marks on the cutting piece to help the workers for easy sewing. You can also use the mark pen to make some special marks on the cutting piece such as the serial number of the product, the size of the product, the manufacture date of the product and etc...You can choose different color mark pens according to the color of your materials.

2) Ink-jet printing - Comparing with the “mark pen” the ink-jet printing technology is a non-touch process, so it can be used for many more different types of materials. And there are different inks for an option such as volatile ink and non-volatile ink, so you can use it in different industries.

5. Red Dot Pointer - Laser Beam Tracing System

The red dot pointer helps as a reference to check where the laser beam will land on to your material by tracing a simulation of your design without activating the laser. As well as your starting point.

6. Automatic Sorting System -

Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

Applications

Applicable Materials

Polyester, nylon, nonwoven and woven fabrics, synthetic fibers, PES, polypropylene (PP), polyamide (PA), glass fiber (glass fibre, fiberglass, fibreglass), Kevlar, aramid, spacer fabrics,3D mesh, filter materials, PTFE, paper, foam, cotton, felt, silk, fleece plastic, viscose, velcro, felts, knitted fabrics, etc.

Applicable Industries

1. Clothing Textiles: fabrics and technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, armchairs, curtains, cushions, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, sandpaper, etc.

4. Textiles used in automotive and aerospace: upholstery interiors, aircraft carpets, cat mats, car seats, seat covers,

sunshades, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes,

paragliding, kitesurf, boats (inflatable), air balloons, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.

Polyester, nylon, nonwoven and woven fabrics, synthetic fibers, PES, polypropylene (PP), polyamide (PA), glass fiber (glass fibre, fiberglass, fibreglass), Kevlar, aramid, spacer fabrics,3D mesh, filter materials, PTFE, paper, foam, cotton, felt, silk, fleece plastic, viscose, velcro, felts, knitted fabrics, etc.

Applicable Industries

1. Clothing Textiles: fabrics and technical textiles for clothing applications.

2. Home Textiles: carpets, mattress, sofas, armchairs, curtains, cushions, pillows, floor and wall coverings, textile wallpaper, etc.

3. Industrial Textiles: filtration, air dispersion ducts, sandpaper, etc.

4. Textiles used in automotive and aerospace: upholstery interiors, aircraft carpets, cat mats, car seats, seat covers,

sunshades, seat belts, airbags, etc.

5. Outdoors and Sports textiles: sports equipment, flying and sailing sports, canvas covers, marquee tents, parachutes,

paragliding, kitesurf, boats (inflatable), air balloons, etc.

6. Protective textiles: insulation materials, bulletproof vests, etc.

Packing & Delivery

Company Profile

GOLDEN LASER, China's first GEM listed company (stock code: 300220)! Accumulated 20 years of experience in laser equipment manufacturing and exporting. Providing the best cost-effective laser solutions!

► Laser innovative application service platform

► Leading laser solution provider

► 20 years experience in laser industry

► Laser-World of Photonics Exhibitor since 2005

► Strict quality control and exclusive after-sales service team

► Providing customized laser machines for users and distributors globally

Golden Laser - Golden Service

• Installation Service

Installation Services are available with all GOLDEN LASER machines. We dispatch technician to customer's factory for installation and preoperation of machines.

• Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

• Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments. Machine warranty is 1 year. We offer flexible extended warranties if needed.

► Laser innovative application service platform

► Leading laser solution provider

► 20 years experience in laser industry

► Laser-World of Photonics Exhibitor since 2005

► Strict quality control and exclusive after-sales service team

► Providing customized laser machines for users and distributors globally

Golden Laser - Golden Service

• Installation Service

Installation Services are available with all GOLDEN LASER machines. We dispatch technician to customer's factory for installation and preoperation of machines.

• Training Service

Our technician is available to your factory and offer training of how to use our machines. As well, you may send your technician to our company to learn how to operate machines.

• Quality Guarantee

We guarantee the quality of machine (e.g. processing speed and working performance is the same as the data of samples making). We sign the agreement with detailed technical data.We arrange final test before shipment. We run the machine for a few days, and then use customer's materials for test. After making sure machine is the best performance, then make shipments. Machine warranty is 1 year. We offer flexible extended warranties if needed.

FAQ

Q1. How does a laser work?

A1. LASER stands for ‘Light Amplification by Stimulated Emission of Radiation’. In the resonator of a laser source – in material processing, these are often CO2 lasers – a special kind of light beam is generated by the action of electric energy. With closed CO2 gas mix laser beam sources, the laser is maintenance-free and uses no laser gas - similar to a

fluorescent tube.

Q2. Which advantages do laser systems have compared to conventional processing methods?

A2. Every day, more application possibilities arise for the use of laser technology in the textile market. Our laser systems for cutting, engraving and marking are meanwhile being used efficiently across all sectors of industry, both for short runs and for industrial mass production runs.

Q3. How does non-contact cutting affect cutting results?

A3. There is more to non-contact machining than meets the eye. In contrast to mechanical processing, there is no physical contact with the material being processed at any time during laser cutting. While knifes, routing machines or punches cause stress to the material, which can lead to undesirable consequences such as damage, laser cutting offers many advantages thanks to this extraordinary property.

NOTE: Different configurations have different prices. The price on Alibaba is NOT real price, please contact us to get the latest quotation. Thank you.

fluorescent tube.

Q2. Which advantages do laser systems have compared to conventional processing methods?

A2. Every day, more application possibilities arise for the use of laser technology in the textile market. Our laser systems for cutting, engraving and marking are meanwhile being used efficiently across all sectors of industry, both for short runs and for industrial mass production runs.

Q3. How does non-contact cutting affect cutting results?

A3. There is more to non-contact machining than meets the eye. In contrast to mechanical processing, there is no physical contact with the material being processed at any time during laser cutting. While knifes, routing machines or punches cause stress to the material, which can lead to undesirable consequences such as damage, laser cutting offers many advantages thanks to this extraordinary property.

NOTE: Different configurations have different prices. The price on Alibaba is NOT real price, please contact us to get the latest quotation. Thank you.

Contact

Please contact Golden Laser for more info. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating or ...?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. What is your application industry? / What is your final product?

5. Your company name, website, Email, Tel (WA...)?

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating or ...?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. What is your application industry? / What is your final product?

5. Your company name, website, Email, Tel (WA...)?

Похожие товары

1500 Вт 3000 4000 экономичная машина для волоконной лазерной резки 1530 1325 высокое качество

1500 Вт 2000 3000 пластина и трубка волоконно-лазерная резка углеродистая сталь нержавеющая металлическая труба листовая Лазерная машина

881 667,20 ₽ - 1 983 751,20 ₽

6090 лазерный гравировальный станок для резки co2 дерева акриловый резиновый лист гравер и резак

308 583,52 ₽ - 385 729,40 ₽

Машина для волоконной лазерной резки б/у небольшая машина

220 416,80 ₽

Волоконный лазер алмазная резка машина для золотого волоконного лазера

220 416,80 ₽

CO2 лазерной резки с камерой для этикеток

374 708,56 ₽ - 385 729,40 ₽

Заводской поставщик машина для лазерной резки ПВХ эпоксидной смолы 4060 мини-машина

99 187,56 ₽ - 110 208,40 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $