Автоматическая маленькая рисовая мельница с рисоочистителем из Таиланда

- Категория: >>>

- Поставщик: Zhengzhou Yogemann Machinery Co. Ltd.

Сохранить в закладки 1600136948557:

Описание и отзывы

Характеристики

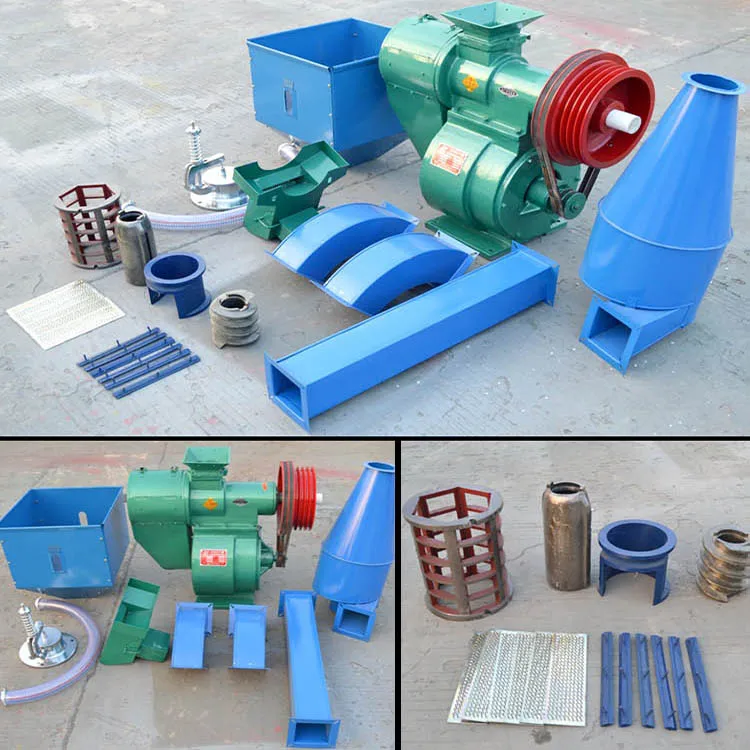

General Introduction of Farm Machinery Rice Polisher Whitener Milling Machines

This product is a combined fine bran rice milling machine, with a crushing device inside, which directly crushes the rice husks while milling the rice. The bran can be directly used as a variety of livestock feed. This product includes models YGM-50, YGM-100, YGM-200, YGM-400 etc. It is an improved rice polishing milling peeling machine. It with the advantages of Advanced structure, beautiful appearance, automatic centering, convenient operation and maintenance, high rice output rate, high quality, large output, low noise, low power consumption, low rice temperature, etc. It has strong applicability to different varieties of rice processing, suitable for all kinds of indica and japonica rice processing, and can process rice into white rice at one time.

Technical Parameters of Rice Polisher Whitener Milling Machines

| Models | Power | Output capacity | Dimension | Weight |

| YGM-50 | 15kw | 900-1000kg/h | 1140*460*780mm | 350kg |

| YGM-100 | 18kw | 1200-1500kg/h | 1740*520*1140mm | 430kg |

| YGM-200 | 22kw | 2500-2800kg/h | 1840*580*1260mm | 450kg |

| YGM-400 | 37kw | 4000-4200kg/h | 1940*610*1320mm | 650kg |

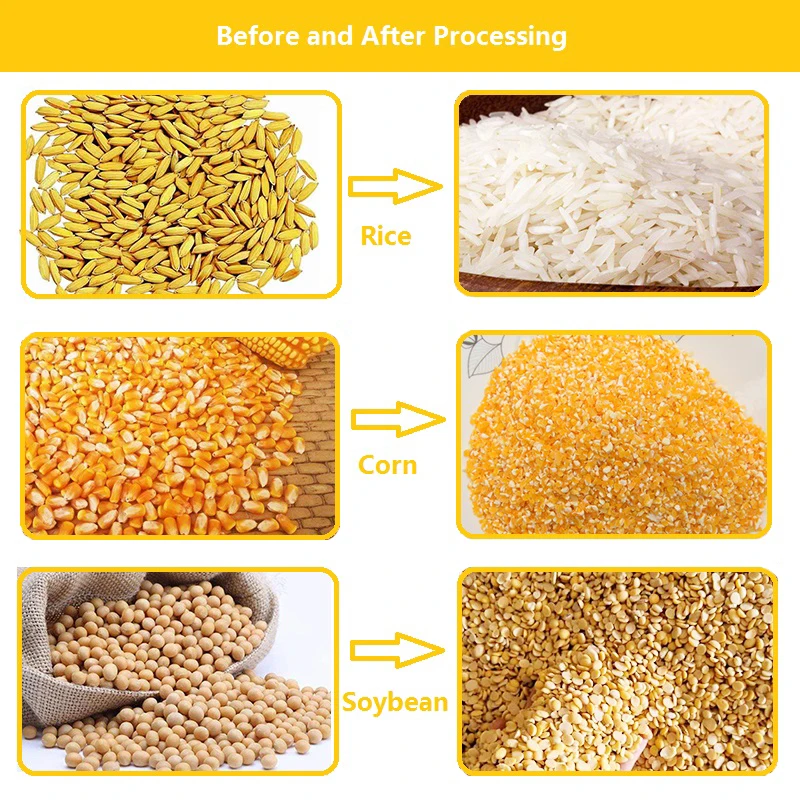

Main Applications of Automatic Rice Polisher Whitener Milling Machines

1. This rice milling machine is suitable for peeling grains such as rice, millet, corn and sorghum.

2. This rice polishing machine has easy operation, easy maintenance, large capacity and excellent peeling effect.

3.This rice milling machine has 6 models, you can choose various machines according to your needs.

Main Features of Rice Polisher Whitener Milling Machines

1. This rice milling machine is compact and reasonable structure, high removal rate;

2. High yield, small cover size, moveable, can driven by the diesel engine;

3. Low energy consumption, high efficiency, smooth rotation, low noise;

4. No dust pollution, simple installation, easy to dismantle and repair;

5. Easy to replace damaged parts and so on.

Working princiole of Rice Milling Machine In Myanmar

1. When the rice milling machine running, first pouring the rice into the hopper, switch on the machine idling for about 5 minutes, slowly pull back the baffle plate, flow regulation, enough is enough, fixed.

2. Then rice by the inlet into the machine, under the action of screw propeller, move forward along the axis, due to export pressure resistance of the door make grain produces pressure, and under the action of roller, mutual friction peeling, grain after reaching the required accuracy, is being exhausted from port a meters.

3. At the same time, produced by high pressure spray wind fan wind by the spindle hole by the milling chamber, into the roller seam, rice bran chaff in the wind into the bucket, the mill at the same time of milling rice husk and rice bran smash together to accept the chaff bag, and took part in the process of grinding white heat, strengthened the crush of rice white effect.

4. The meter accuracy control is determined by the resistance mechanism of pressure spring, adjustable size.

5. The cleanliness of the finished rice is controlled by the position of the air volume regulating handle on the right side of the rice hopper.

6. If the air volume is too strong, the rice grains will be absorbed into the chaff. If the wind force is too weak, the chaff will be contained in the finished rice.

Packaging:

All of our machine are packed with plastic films inside and fumigation wooden case outside. Our wooden case is very strong, it can bear long time shipping on the sea, or the Express/Airflight delivery. What's more, machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

Delivery:

Upon receipt of payment, delivery date will be in 7-15days after receive the despoit.

By Air, Express (DHL, Fedex, TNT, UPS, EMS. etc), by sea.

Shipping freight will depend on the destination, shipment method, machine's size and weight.

- Payment Term: The payment term can be negotiated and agreed upon between the Parties. Usually T/T 30% deposit after order confirmed, the balance paid before delivery

- Leading Time: Normally in 3 weeks after deposit received.

- Shipping port: If by sea shipping, Qingdao, Shanghai, Yiwu, Guangzhou or per your request.

- Discounts: We offer discount for long term cooperated customers.

- Machine Voltage and Frequency: we can customized according to your requirement.

- Shipping Service: We have long-term well relationship with many sea freight forwarders and sea shipping company, so we can provide competitive LCL and FCL shipping service.

Company profile

1. Zhengzhou Yogemann Machinery has 15 years manufacture experiences in this food trailer field in China.

2. Has exported to more than 3000 customers from more than 100 countries, such as: Mexico, India, South Africa, Ghana Colombia, Brazil, Argentina, Belgium, Sweden, Iceland, Egypt, Syria, Greece, South Africa, Algeria, Australia, USA, UK, Canada, Thailand, Singapore, Malaysia, Indonesia, Russia, Pakistan ect.

3. We promise machine keep working over 10 years in good working condition, long-terms service life of our trailer. Fewer easy broken parts, easy to change and repair.

4. One years warranty time, and can send you free spare parts for replace.

Certification

All our products have CE certification.

As a company which has designing capability and producing experience, we pay much attention to the personalized designs of the product usage and safety. Until the year of 2018, we have more than 30 patent and awarded “Chinese design award of excellence”.

At the year of 2017, we became an official member in good standing of the Silk Road Chamber of International Commerce.

And we are also a “ Canton Fair Complex Designated Catering Equipment Supplier” since 2015.

Our customers from all over the world

Exhibition of our company from 2010

Похожие товары

Строительное оборудование, кран новейшего дизайна, башенный кран превосходного качества TC7022 -12 тонн, распродажа

Классическое деревянное пасхальное яйцо без рисунка с держателем для детей DIY живопись

Комплект для ремонта S4L2 с комплектом прокладок цилиндра поршневые кольца подшипники клапаны для двигателя грузовика

Прямая продажа от производителя, плюшевый кролик, мягкая игрушка

Совместимый Canon NPG-51 NPG51 GPR-35 GPR35 EXV-33 EXV33 порошок для электростатической печати для Canon ImageRUNNER 2525 2520 2530 копир тонер-картридж

Полный и запасной круглый оросительный разбрызгиватель для площадки

Лидер продаж 2016, микроблейдинг, татуировка, игла #12, ручная Татуировка бровей

Новые поступления

Новинки товаров от производителей по оптовым ценам