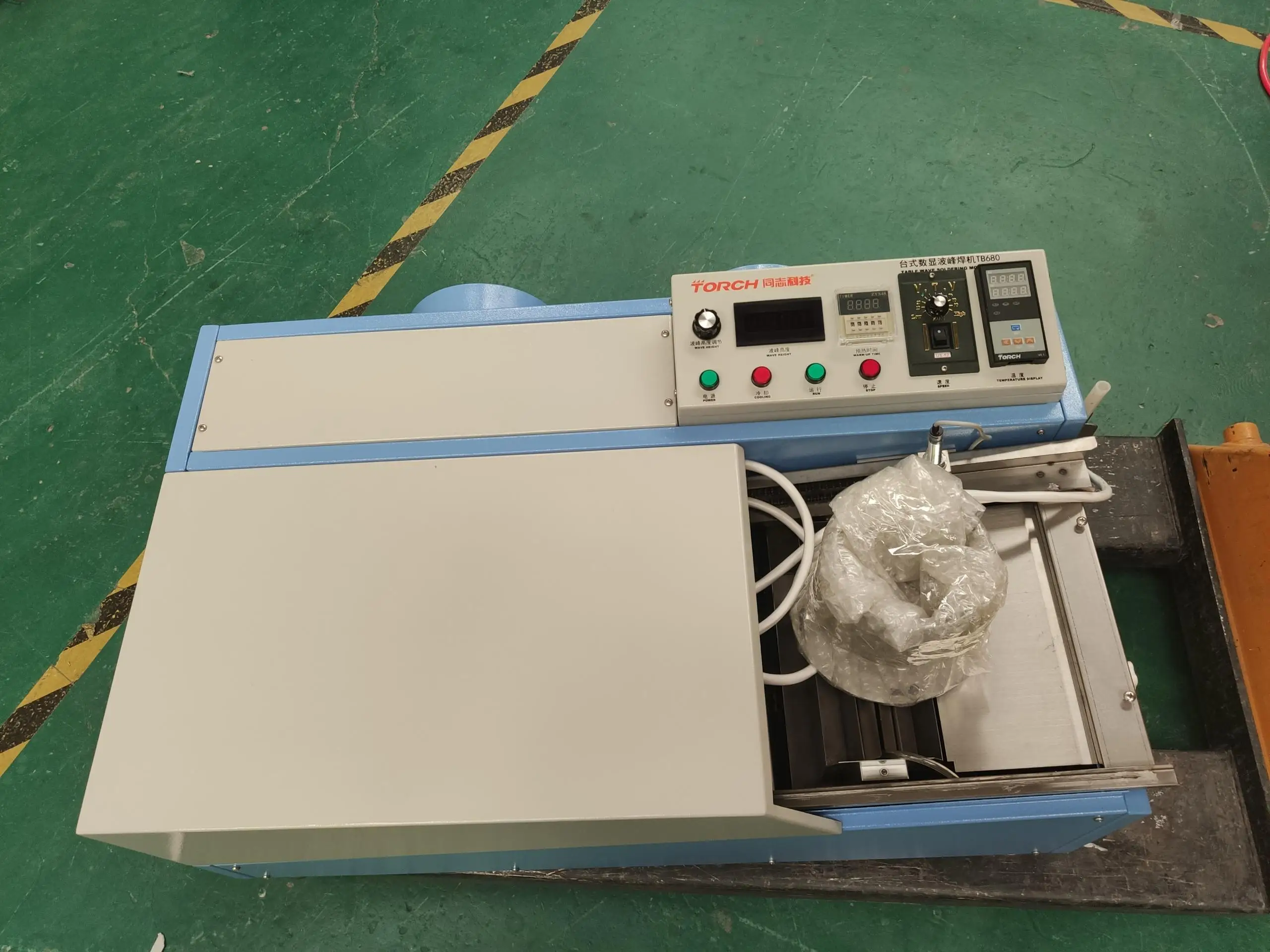

Аппарат для пайки печатных плат Jet Wave сварочный аппарат DIP в Китае

- Категория: >>>

- Поставщик: Beijing Torch SMT Incorporated CompanyBeijing Company

Сохранить в закладки 1600149253311:

Описание и отзывы

Характеристики

Summary

Desk wave soldering machine TB680 has been developed by Torch, It is the first equipment in small type wave soldering field. TB680 is suitable for research center, war industry, middle- and small-sized corporation, small private corporation and other electronic production companies. It is a desk-type, taking up small room, with multi-functions, energy-saving and high efficiency. The operation is easy and especially suitable for small and middle batch production.

Main technology parameters

Model | TB680 |

The max power consumption | 3Kw |

Solder pot capacity | 37Kg |

PCB width (L×W)(mm) | 200 * 270mm (Max) |

Temperature range | 200-300°C LED display |

Preheating temperature | 70-90°C |

Wave height adjust range | 5~ 12mm |

Melt time | 80min |

Spray work mode | froth |

Power supply | 220V±1%V AC single phase 50Hz (please connect power to the ground) |

Conveyor speed | 0.5~ 3m /min CTV |

Dimension | 90*57*41cm |

Weight | 65Kg |

There are 6 parts: flux, preheating, soldering, electrical controlling, exhaust unit and convection unit.

1 Flux

Flux parts are made of air pump, air tube, pin valve, filter, froth tube and flux box.

There is flux belt on the froth tube, PCB whose side has chips is on the top and touch flux, the side will has flux film.

2 preheating

It is made by melt board with resistor to provide heat for PCB.

3 soldering

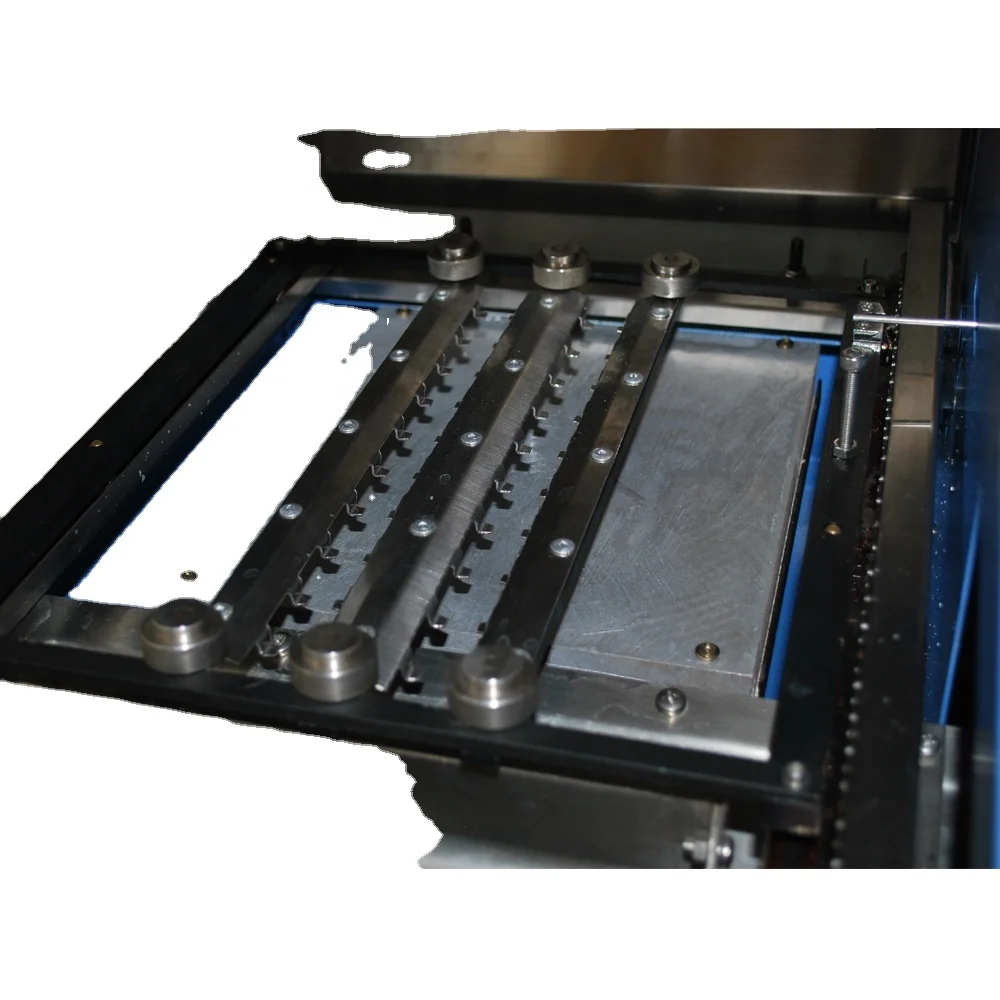

It is made by tin pot, heating board, wave pump and tin.

1 tin pot

2 clapboard

3 nozzle

4 regulator

5 wave pump

6 channel

Figure 3: The solder will be divided into upper and lower levels by clapboard, the lower for the high-pressure layer, the upper layer for the low-pressure layer, liquid solder will be into high pressure layer driven by wave pump, the solder in the high pressure layer rotate and then pass regulator, it will overflow from the nozzle, the wave crest form and then fall into low pressure layer because of gravity

4 electrical controlling

With modular structure, transmission speed, solder temperature, preheating time and others can be adjusted and controlled. Working principle is shown in Figure 4.

Figure 4 electrical controlling

5 exhaust unit

It is made of cover, air fan, air cover and air tube. All exhaust generated in soldering will be eliminated.

6 convection unit

It is made of chain, rail, drive and pallet. PCB will be sent in flux unit, preheating unit and soldering unit by convection unit.

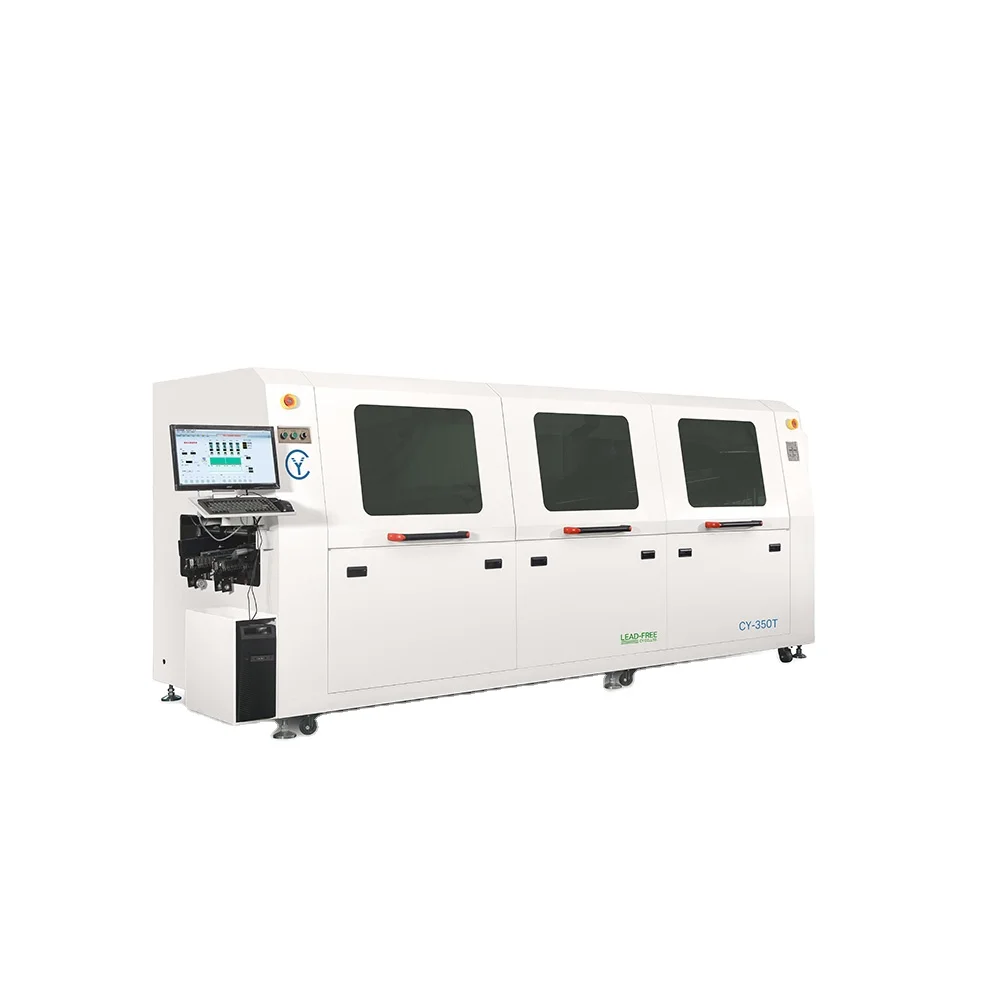

TB 680 Mini desktop wave soldering machine for 200*270mmPCB TB780D Midium wave soldering machine for 50-250mm PCB

TB880C Big wave soldering machine for 50-300mm PCB

TORCH CO,. Ltd was found in 2001, focus on R&D and production of SMT equipment. It has been the leader on SMT industry in domestic. TORCH Co,. Ltd keeps the faith “Intelligent production, Intelligently create future” and developed many SMT equipment by itself. At present, TORCH C., Ltd owns more than 100 patents, brands and software rights. Moreover, it also passed ISO9001, CE and other certifications. Strategic objectives: to optimize the technology based on keeping the existing mature development, production, sales and service mode and continue to consolidate and strengthen its advantage position in the SMT electronic equipment field, with existing key products as the center, to expand the supply chain has become the Internet + intelligent manufacturing electronic factory of 2025 and the overall solution project of industrial upgrading optimized brand.

Похожие товары

Лучшая цена Горячая Распродажа светодиодная проволочная сварочная машина для металла автоматическая паяльная

Автоматическая производственная линия ccd система камеры паяльный робот с линией CE

Высокоскоростной кабель передачи CXP SAS SATA паяльная машина для жесткого диска

Автоматическая проволочная паяльная машина 3Q цена

Ручной паяльник PCB бессвинцовая паяльная машина с титановым соплом

CY Pcba полностью автоматическая селективная установка для сварки волновая Пайка электронных продуктов Лидер продаж

Shenzhen SMT производственная линия PCB сборочная машина автоматизированные высокоскоростные производственные линии известный бренд

Новые поступления

Новинки товаров от производителей по оптовым ценам