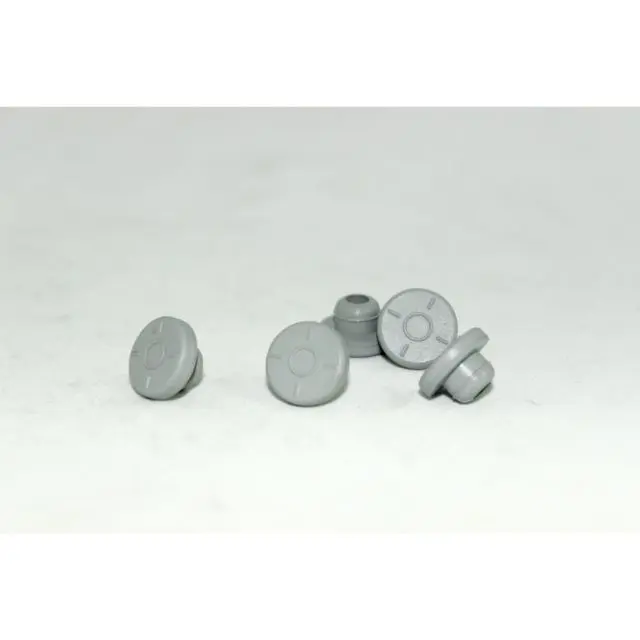

Высококачественная резиновая пробка 20 мм

- Категория: >>>

- Поставщик: KESARIA RUBBER INDUSTRIES PRIVATE LIMITED

Сохранить в закладки 1600155016500:

Описание и отзывы

Характеристики

High Quality 20mm rubber stopper

Rubber Stopper: These are used for protection of cover hole, a wire, tube, or various other objects from abrasion when they are passed through metal, plastic, or any material that could damage the outside surface of the item while being installed, or when in use.

Additional applications include electrical insulation, noise reduction, vibration isolation and protection from forces generated in compression. There are different types of grommets for a variety of applications.

Important size dimensions need to be considered when specifying grommets include inside diameter, outside diameter, thickness or working height, groove thickness and groove depth. We manufacture Rubber Grommets of different shapes & sizes made from a variety of rubber grades like SILICON, EPDM, TPR, NBR, NEOPRENE, SBR & NATURAL. The hardness rating on a Shore A scale for Grommets can be 30 ~ 85 durometer. Exact specifications should be clarified by our engineers, as chemical and physical properties of grommets can differ based on manufacturing technique & application.

Certificate | Sample Time | Color | Payment Mode |

ISO, IATF | 3-10 Days | Can Be Coustomized | T/T , LC, Paypal |

Small quantity packed in polybag. Then it is further packed in hard carton. Carton is wrapped with shrink pad and finally it is wrapped in tough pp bag.

For Delivery we have logistic partner such as FEDEX, DHL, ARAMEX.

Kesaria Rubber Industries became functional under the able leadership of Mr. K.L. Jain in 1989. Production started in a small, rented place with a workforce of only five people.

1989 : Manufacturing Of Rubber Parts In Gurugram

1997 : Converted to Private Ltd Company

2004 : Moved To A Bigger Factory Space In Binola ( Near Manesar- Gurugram )

2010 : Diversified into Manufacturing of PTFE Components

2015 : Addition Of Double Colour Plastic Injection Moulding

2018 : Scaled Up To approx 50,000 Sft

With Enriched experience of 29 years, Kesaria Rubber has become a leading manufacturer & supplier of Rubber, TPE & PTFE parts supplying not only to complete India rather exporting to European, Asian and North East African countries as well.

Our Mission: Is to provide Sealing Solutions for a wide range of industrial applications, through our well defined processes by using latest technology. We provide consistent quality & timely delivery to our customers by conforming international standards & with the help of professionally skilled manpower for ensuring ever lasting relationship with our customers

Our Vision: Is to be a global leader providing reliable sealing solutions by 2024

Our Value

Integrity

Mutual Trust & Cooperation

Recognise & Appreciate

Quality Obsessed

Result Focussed

Enjoy Work

Infrastructure

Facilities at Kesaria include a completely integrated manufacturing plant and a full fledged testing lab at Gurgaon, Haryana. We are fully equipped with modern infrastructure, high-precision machineries, latest process equipment and sophisticated testing facilities for checking physical and chemical parameters .Our highly qualified designers and engineers utilise the latest CAD technology and tooling machines to provide fast & efficient tool designing and development services.

The company not only ensures the quality of the products currently being manufactured but also works on constant updating of technologies and new products. Safety, durability, and aesthetic appearance are the indispensable features of our value-added components in addition to great functionality.

Quality Control

Kesaria has always met the ever-growing demands of its discerning clients, thanks to its stringent quality control measures and research & development efforts - undertaken to exceed global standards. We are always striving to produce precision rubber products that feature the highest possible specifications. The focus is, therefore, on a consistent manufacturing process, backed by the continuous technological up-gradation.

Our R&D experts also provide support & assistance to our valued clients as and when required. These standards are reviewed and upgraded regularly and each procedure is backed by intelligent concepts & requisite instrumentation. At Kesaria, the skilled use of high-precision testing equipment and simulation devices help us ensure absolute qualit

Why Us ??

400 OEM Customers

Complete In-House manufacturing facilities

Enriched Experience of 28 years

Production of nearly 1.5 Million Parts Per Day

Product size range from 2mm ~ 500mm Diameter

More than 40 Engineers & Executives

Nearly 200 strong & skilled workforce

ISO 9001:2015 Certified Organisation

Well defined workflows & processes

High Quality at best price with effective service

For any further queries, feel free to contact us at www.kesaria.com

Phone Number - 091- 9718114446

Name - Parvez Arif Khan

(Export Manager)

Похожие товары

BNT проекционный экран с ручным потолочным креплением с самоблокировкой 100 дюймов

Зеленый чай Pandan 9371chunmee Flecha, мусульманский чай с рассыпными листьями

Здоровый сладкие напитки Ингредиенты 1L пандана 3 слоя чайный сироп упакованы в пластиковой бутылки

Модные женские перчатки из искусственной кожи на меху зимние толстые водонепроницаемые длинные женские кожаные перчатки

SNOWHITE 100 дюймовый Ультра короткий бросок мягкий проекционный экран с линзой Френеля ust alr с фиксированной рамкой экран проектора

Оптовая продажа сушеных листьев пандана, черных бобов для детоксикационного чая

Высушенные листья пандана из Таиланда

Новые поступления

Новинки товаров от производителей по оптовым ценам