Высокотемпературный керамический ролик для закалки стекла печи

- Категория: Other Quartz Products >>>

- Поставщик: Zibo Supereal Industrial Ceramic Co. Ltd.

Сохранить в закладки 1600155242566:

Описание и отзывы

Характеристики

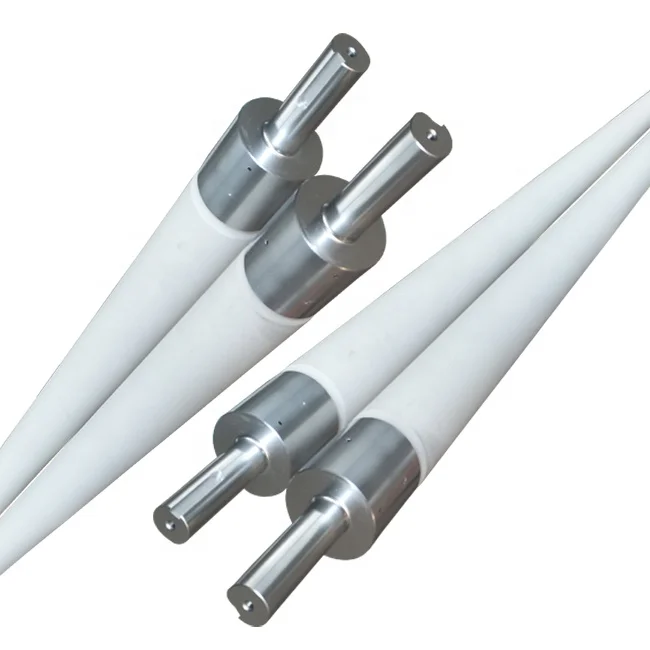

High Temperature Ceramic Roller For Glass Tempering Furnace

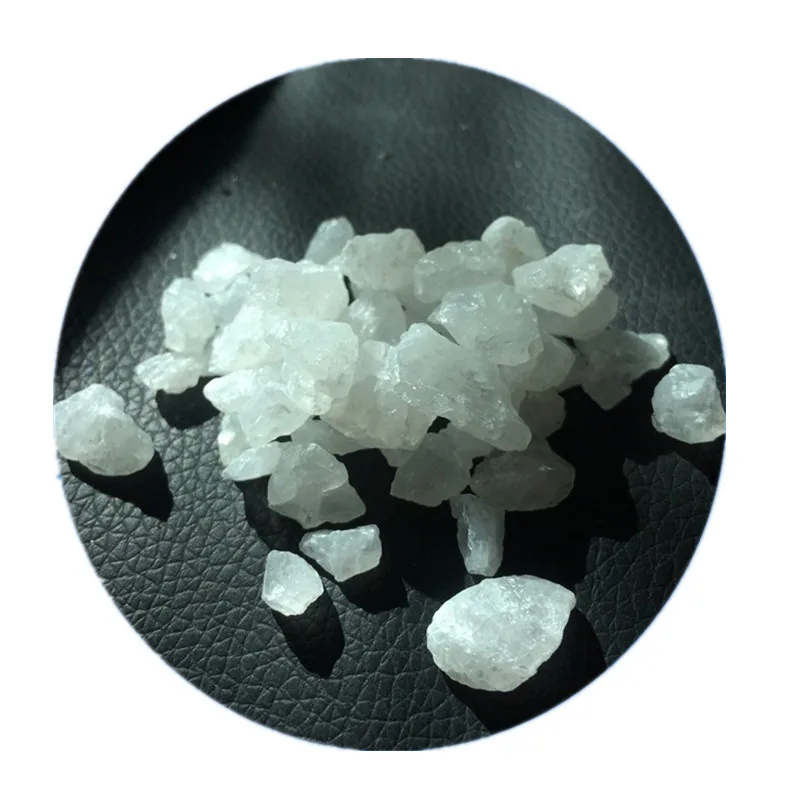

High Temperature Ceramic Roller For Glass Tempering Furnace adopts high purity silica powder as raw material and made by advanced grouting molding technique and processing manufacturing line.Fused silica ceramic roller can be used as the key part of the floating glass or steel furnace to bear and transit the glass or steel plate. The service temperature is about 800 C in glass production industry and deep processing industry.

1. Typical Technical Parameter :

| High Temperature Ceramic Roller For Glass Tempering Furnace | ||

| Item | Unit | Data |

| SiO2 Content: | % | >99.5 |

| Bulk Density: | g/cm³ | 1.92-2.00 |

| Open Porosity: | % | 7~11 |

| Compressive Strength: | MPa | ≥55 |

| Flextural Strength: | MPa | ≥25 |

| Thermal Expansion Coefficient: | ×10-6/K-1 | ≤0.6 |

| Conductivity (20℃): | W/m·K | 0.64 |

| Conductivity (800℃): | W/m·K | 0.55 |

| Max. Working Temperature: | ℃ | 1100 |

2. Brief Introduction of High Temperature Ceramic Roller For Glass Tempering Furnace:

Made from high purity of material composition SiO2, our fused silica roller/ fused silica quartz roller with very low thermal expansion and excellent thermal shock resistance, is the right choice for a variety of glass manufacturing, glass transformation, steel processing and non-ferrous metal processing, especially for the kilns which produce safety glass for architectural or automotive usage.

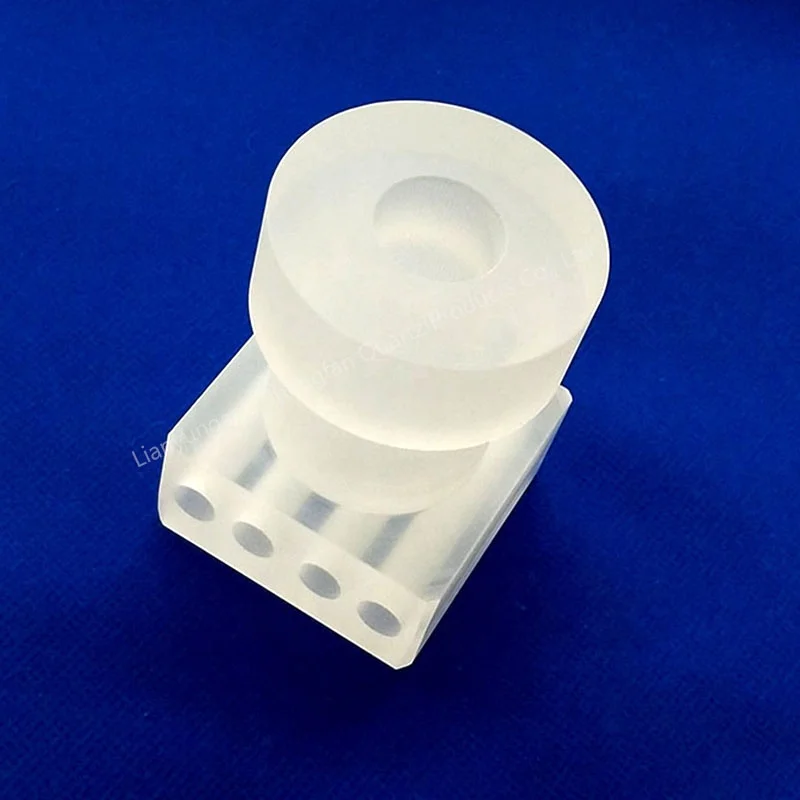

Some fused silica quartz ceramic roller show:

As an alternative, we can also offer the fused silica rollers with metal cap in a variety of designs.

3. Characteristics of High Temperature Ceramic Roller For Glass Tempering Furnace:

♦. Good surface smoothness, no scratch to glass , no pollution to glass

♦. High density without bubbles

♦. High precision in size

♦. Raw material with high purity, excellent chemical and physical properties

♦. Very high compressive strength, flexural strength & impact strength at high temperature

♦. Very low thermal expansion coefficient

♦. Excellent thermal shock stability

♦. No deformation under high temperature

♦. Small radial beat (runout)

♦. Long service life with reliable axle neck joint technology (Anti-loose technology)

♦. High economic efficiency, can reduce the overall cost of belt conveyer, reduce maintenance

4. Application of High Precision fused silica guide roller for annealing furnace:

Due to the perfect mechanical properties and special surface quality, our fused silica roller/ fused silica quartz roller is mainly used in the horizontal tempering furnace to transport heat treating glass.

Some application situation of fused silica quartz ceramic roller for tempering flat glass:

5. Packing and Shipping of High Temperature Ceramic Roller For Glass Tempering Furnace:

Strong, Safe, Safe, Durable, Compact and Environmental Packing for long-time transportation by sea, plan or truck ......

Zibo Supereal Industrial Co., Ltd, located in Zhangdian Economic Development Zone in Zibo city is focusing on high alumina ceramic products, here you can realize an one-stop shopping for complete wear and erosion protection solutions in wide range of industries including Power Sector, Mining, Cement, Metallurgy, Coal Washing, Steel& Iron Plant, Railway, Port and so on.

Along with the business development and the strong support of factory, we have just introduced and added fused silica quartz ceramic roller for tempering flat glass as our major sales products too.

Our company has a rigorous quality control system to guarantee stable performance and proven quality, our professional inspection team will carry out full course tracking from raw material selection, batching, production process management to semi and finished products test. Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our products have been approved and accepted by clients and users from Vietnam, South Korea, India, Russia, Italy, Poland, USA and etc.

Besides the superior quality, Zibo Supereal Industrial Co., Ltd also earned a good reputation for fast deliveries, competitive pricing and outstanding customer service.

◊ Professional: 11 years of experience in production, more than 5 years of experience in foreign trade export, we will supply prompt technical support on pre- and after sales.

◊ High Quality: Based on the strict adherence to ISO9001-2008 or Industry Standard or other International Standard, our inspection engineers carry out full course tracking in the whole production.

◊ Focus on Details: No matter how small questions or problems shall be replied and help to solve by our members timely, even for the small orders.

◊ Price &Discount: We can provide competitive price and discount for large quantity.

◊ OEM : Customized designs, sizes and logos are acceptable.

Похожие товары

Wholesale Frosted Quartz Crystal Singing Bowl

Китайский производитель, высокочистый кварц, белый силикагель, песок, цена за тонну

Чакра из камня обсидиана, чакра, 10 дюймов

Запчасти для холодной очистки кварца, используемые в автомобиле

Минералы KIRAN-Цена 325 сетки класса А, белый кварцевый порошок от Bewar Rajasthan

Оптовая продажа, Китай, чистый белый силикагель/кварцевый песок для изготовления стекла

Самый популярный товар, аметистовая чаша с ручкой, кварцевый хрусталь, пение по цене производителя

Новые поступления

Новинки товаров от производителей по оптовым ценам