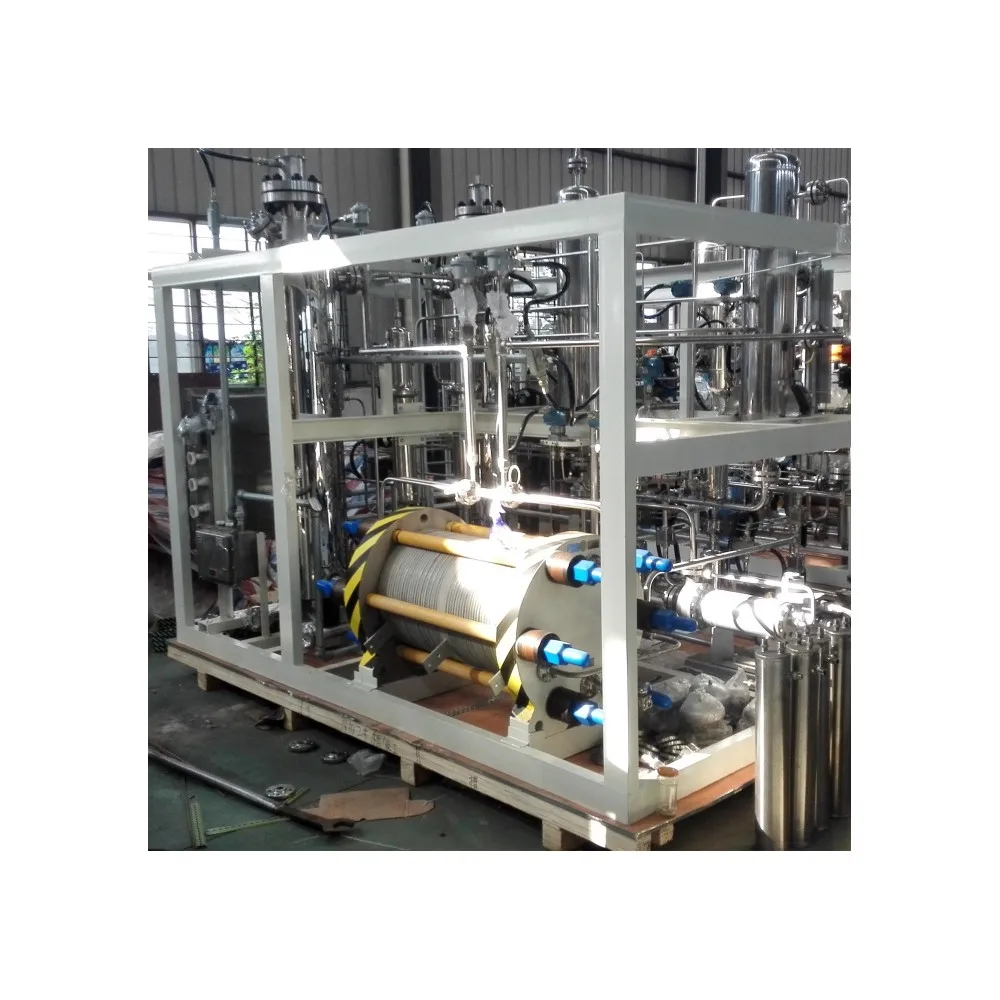

360м 3/ч турбинный расширитель с воздушным подшипником для сепарации воздуха

- Категория: >>>

- Поставщик: Jiangsu Wintek Industrial Technology Co. Ltd.

Сохранить в закладки 1600165027785:

Описание и отзывы

Характеристики

Our Services

Model | Flow | Inlet Pressure | Discharge Pressure | Inlet Temperature | Efficiency | ASU | Note |

Nm3/h | MPa,G | MPa,G | K | % | |||

PLPK-6/6-0.42 | 360 | 0.6 | 0.042 | 130 | 76 | 180m3/h ASU |

|

1. Description

PLPK-6/6-0.42 turbine expander unit is one of corollary equipment for air separation plant(ASP). In the complete set, it uses air rich in oxygen adiabatically expand to produce needed cold for air separation plant to obtain cryogenic directly, and complement all loss coldness of ASP. Adiabatic efficiency of turbine expander affects directly normal running of ASP and each technical and economical index. Also it has a simple structure, high adiabatic efficiency, small volume, light weight, convenient operation and maintenance.

2. Structure introduction

2.1 Turbine expander

The expander is horizontal, one-stage, radial-axial-flow, centrifugal strike back. Two turbine expanders have the same parts. Volute type is single inlet, tangent direction flow type, and its material is cast copper, volute of turbine expander works under cryogenic and is kept in cold preservation box.

Expansion impellers use half-open radial inward counteraction type.

Brake blower uses half-open radial straight impeller.

Expansion working wheel and brake blower are separately fixed at the two ends of shaft. Shaft is supported by two gas bearings, gas bearings are fixed in dry tank body, and it applies integrated shaft assembly structure. Behind impeller, main shaft section has fixed a shaft sealing device where normal temp., dry air is filled with pressure 0.04~0.05 MPa(G) (0.4~0.5kgf/cm2), thus to reduce the refrigeration loss of expansion air.

On the side end of brake blower, an electric gas remote tachometer is fixed to indicate running condition on instrument tray.

2.2 Gas supply system of gas bearing

Special supply system is for gas bearing, and a part of purity air from molecular sieve purifier passes crude filter and refine filter to be supplied to gas supply pipes of gas bearing. Gas consumption of gas bearing is about 25m3/h (under supply gas pressure ~0.6MPa(G).)

3 Safety equipment

Turbine expander is a high speed rotation plant. For protecting it, it is fixed on an automatic safety system.

3.1. The plant should be regulated when alarm signal is sent out in following condition.

Pressure of bearing gas is lower than 0.49 MPa.

3.2. Under the following conditions, stop the unit.

a. Pressure of bearing gas is lower than 0.45 MPa, and it can’t be regulated.

Power trouble.

3.3.3. Over speed control

Load of brake blower is controlled by outlet valve to regulate its rotate speed. It can be regulated by inlet valve when the outlet valve is invalid.

4. Operation

When air separation plant is started, in order to cool the air separation plant quickly, two sets of turbine expander should be started in sequence. Only one set will be used under normal operation. Each set is an independent system and their operation is the same.

4.1. Preparation before starting

4.1.1. Blow off each inlet and outlet piping of turbine expander completely, and then mount the machine.

4.1.2 After bearing gas supply piping and sealing gas piping are completely blown off, nickel sheet of refined filter is fixed. If filter core used for a long time has been contaminated, it should be cleaned strictly before used again. After finishing blowing, bearing gas system and sealing gas system are switched on, at the same time power supply system of instrument and tachometer are switched, so that they are in good condition. Seal should be removed in the discharge hole of shell.

4.2. Starting

4.2.1. Step

4.2.1.1. Regulate gas supply pressure of bearing gas and keep it at 0.5 ~0.6MPa. For the first starting, in order to confirm whether rotor is floating, it may be observed from the discharge hole of the shell body.

4.2.1.2. Outlet pipe is expedited, and valves are open fully.

4.2.1.3. Open outlet check valves fully, and close inlet shut off valves of turbine expander.

4.2.1.4. Open inlet shut off valves of turbine expander slowly to make the inlet pressure gradually rise.

4.2.1.5. Regulate pressure supplied to sealing gas to be ~0.045 MPa.

4.2.1.6. Start another expander per the same step.

4.2.2. Notice Items

4.2.2.1. During starting, as expander departs designing work condition for running, running parameters change greatly and adjustment is frequent. When starting, whole plant is at hot state, inlet temperature of turbine expander is higher than normal value, but outlet pressure of turbine expander is lower than normal value, because adiabatic efficiency of turbine expander is higher than that of expansion piston, so the temperature drops very fast in the course of starting, inlet temperature of turbine expander rapidly falls down, at that time opening degree of inlet valve should be big in time to raise the inlet pressure of turbine expander.

4.2.2.2 At the beginning phase of staring, inlet temperature is high. Inlet gas capacity of one expander can not reach full load, and end stage of air compressor can vent some gas. With the inlet temperature dropping, turn down vent valve and regulate it to request.

4.2.2.3 At the latter phase of staring, with the inlet temp. dropping, inlet pressure can not keep at 0.39MPa. Then it can reduce the capacity of expander, so that it can assure another expander is working at the rated speed of 46630r/min.

4.3. Running

4.3.1. Parallel working and switch-over of turbine expander

As inlet piping is public for two turbine expanders when two sets running at the same time switches-over to one set single running, nearly take notice of another set to prevent it over speed, and it should be operated slowly. For stop of expander, pressure of bearing gas should be remained at 0.10 ~ 0.20 MPa(G) to prevent impurity entering the bearing.

4.3.2. Thawing and blow off

If distributor is blocked up by ice or dry ice in the course of running, the efficiency of turbine expander will be low, so turbine expander must be switched-over to thawing, and the time lies on actual operation.

4.3.3 Thawing should be carried out in the following conditions:

Outlet pressure of nozzle is dropping.

Speed is falling down.

Flow is reducing.

4.3.4. Method

Dry hot air is for thawing until air outlet dew point temperature reaches about 30℃. Dry hot air flows from thawing valve of expander--expander-- blow off valve.

4.3.5. Notes

When thawing, inlet and outlet shut off valve of turbine expander should be closed fully, and blow off valve should be open fully.

Flow direction of heating air is opposite to that of normal working gas flow, and thawing should be carried out in the condition of bearing gas supply.

After turbine expander is stopped, in order to protect plant, it must be thawing for one time.

4.3.6. Regulation:

Adjustment of turbine expander mainly lies on the need of cold capacity for air separation plant. Common regulating method is adopted by throttling before expander. Adjust of temperature before expander is mainly to avoid temperature after expander is too low, and prevent liquid drops producing to make plant damaged. In condition that cold volume is rich, if inlet temperature is too low to be adjusted high, throttling before expander should be used to make expander run with low load, assuring at outlet temperature liquid drops not being produced.

4.4 Stop

4.4.1. Step: stopping step is opposite to starting step.

4.4.1.1. Gradually close inlet valve, and then close outlet valve of turbine expander.

4.4.1.2. When the reading of tachometer is reducing to be zero, close sealing gas and pressure of bearing gas should be depressed to about 0.15MPa(G).

4.4.2. Emergency stop: in following condition, emergency stop must be used.

Speed, pressure, temperature and flow capacity is very abnormal.

Vibration and noise are abnormal.

Gas bearing is stuck.

4.4.3. Sudden power off:

Except immediately close inlet valve of expander, at the same time, other steps should be taken according to emergency stop of air separation plant. After trouble is shot, each preparing work should be done well for starting next time.

5. Maintenance, assembly, trouble shooting

5.1Maintenance

Except accident happened, turbine expander unit can continuously go on running with air separation plant, in normal condition, overhaul isn’t needed, if overhaul is needed for actual facts, specified requirements should be followed.

5.1.1. Requirements for checking turbine expander

5.1.1.1. Clearance of every part should be in accordance with the data offered by assembly clearance.

5.1.1.2. Bearing is allowed to partially repair in condition that dimension precision and roughness aren’t affected, it should be cleansed strictly after being repaired, and it should be blown to clean by high-pressure pure gas.

5.1.1.3. In order to assure dynamic balance performance of rotor, rotor should not be free to replace parts or change position, after being repaired or replaced parts, dynamic balance should be proofreaded before being put into use. Displacement of center of gravity for rotor is no more than 0.3μm, when rotor being disassembled and assembled, scale line of original impeller, impeller of boost blower and auxiliary components should be paid attention to. The biggest offset of scale line will not exceed 10o~15o, otherwise running balance of rotor should be verified again.

Normal trouble and trouble shooting

6.1 Speed of turbine expander out of control

This turbine expander is directly braked by blower. If the filtration mesh on inlet filter is blocked by dust or impurities, the speed of expander may rise up and out of control. Therefore, it is necessary to wash the inlet filter timely.

6.2. Too low temperature at back of turbine expander

In such condition (Outlet pressure of expander is 0.032MPa, discharge temperature falls down as discharge pressure falls down when starting), it is easy to produce liquid drops to damage impeller. At this moment, temperature before expander should be regulated, and by-pass regulating valve should be adjusted. If inlet temperature is too low to adjust high, turn down opening degree of inlet valve for expander or depressurize inlet pressure of expander etc, to make speed of expander fall down and expander run with low load.

6.3. Over speed when turbine expander starting

When starting, over speed of turbine expander is caused by two reasons, one is too impetuous opening inlet check valve and too large gas volume, the other is inlet and outlet piping of brake blower blocked. None but inlet and outlet of blower are clear, resistance of piping is smallest. At this moment needed wind pressure is low. According to characteristic curve of blower, the lower wind pressure, the larger corresponding wind capacity and power consumption. So needed power by blower with lower speed can balance output power of expander. So when starting the plant, on the one hand slowly open inlet check valve of expander, on the other hand remember to make the inlet and outlet piping of blower clear to prevent over speeding.

6.4. Too low pressure in front of turbine expander

Any part in whole passage is blocked or resistance too large before expander, all that will cause pressure before expander dropped. Too low pressure before expander will make expansion capacity and unit refrigerating capacity reduce, then bring total refrigerating volume reduced, so it must be banished.

Reason that brings pressure before expander too low perhaps is that heat exchanger or filter of expansion gas is blocked by mechanical dust or dry ice. It is necessary to blow off or thaw, cleanse filter or go on analyzing purification efficiency of molecular sieve purifier.

6.5. Too high pressure at back of turbine expander

Oxygen-enriched gas after turbine expander goes to regenerate in purifier after reheated by heat exchanger. If resistance after expander is too large, or resistance of heat exchanger is large, pressure after expander will be too high. As expansion ratio falls down, expansion refrigerate capacity reduces, that perhaps bring cold of plant imbalance, above situation must be treated in time. If resistance of filter and heat exchanger is large, which brings pressure after expander too high, the expander must be cleansed, blown off, adjusted to normal value. At this moment pressure after expander should fall automatically to original value, otherwise it should find out reason from piping after expander by checking its resistance or clearance between impeller and inner diffuser etc to banish.

6.6. Great vibration of turbine expander

Reason that brings turbine expander vibrated greatly is too much. It mainly has following several aspects:

6.6.1. Dynamic balance of rotor is not good

Rotor has done dynamic balance test strictly before being delivered, its displacement of center of gravity and imbalance weight are all controlled in allowable range. Dynamic balance precision of rotor is 0.3μm, but during assembling, dismantling and running process, because rotor is worn-and-torn and misaligned or mechanical particles in rotor is frozen, all that will destroy dynamic balance of rotor, then cause great vibration. Expander should be stopped to check, if necessary the rotor should be done dynamic balance test again to see whether it exceeds allowable range.

6.6.2. Liquid appearing in turbine expander

When liquid appears in expander, as liquid is thrown to outer edge of impeller, its temperature rises, liquid vaporizes rapidly to make clearance pressure fluctuated in large range and then make expander vibrated. In this condition, pressure gauge beats rapidly, temperature indication fluctuates. The expander should be stopped immediately.

6.6.3. Surge of brake fan

When pipes of fan and filter blocked, working point of fan will be in the astable vibration range, which causes fan vibration, working point of fan perhaps enters into surge section to bring fan instable and then make turbo-expander shaken. The phenomenon is easier to judge and banish. It needs to wash the filter and blow the pipes.

6.6.4. Too low pressure of bearing gas supply

For certain gas supply pressure Ps, running of gas bearing turbine expander is very stable. Supply bearing gas pressure of the expander is specified over 0.5MPa (G). Too low supply gas pressure makes turbine expander run abnormally.

Q1: How about the quality of your products?

A: Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q2: How about the price?

A: We are manufactory, and we can give you lower price than those trade companies. Besides, customers from Alibaba can geta discount.

Q3: Do you provide after-sale service?A: Yes. The warranty peniod of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Похожие товары

Лучшая цена на испаритель окружающего воздуха СПГ

Промышленный генератор азота PSA завод высокого давления потока для продажи

Низкоэнергетический генератор азота PSA завод высокого давления для сохранения пищевых продуктов

Генератор азота высокого давления для пищевой промышленности

Генератор азота высокого давления PSA Цена генератора для упаковки пищевых продуктов

Индустриальный концентратор кислорода 3 л/мин

21002A H-10 генератор водорода

Новые поступления

Новинки товаров от производителей по оптовым ценам