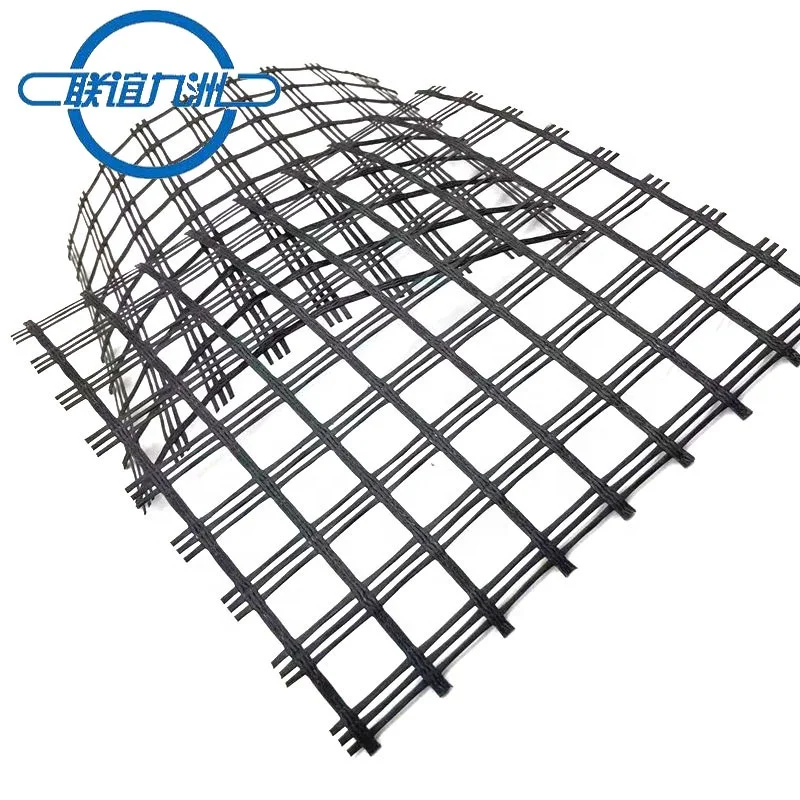

Экструдированный пластик георешетка геометрический композитный Геотекстиль

- Категория: Геосетки >>>

- Поставщик: Feicheng Zhengli Geotechnique Material Co. Ltd.

Сохранить в закладки 1600166342904:

Описание и отзывы

Характеристики

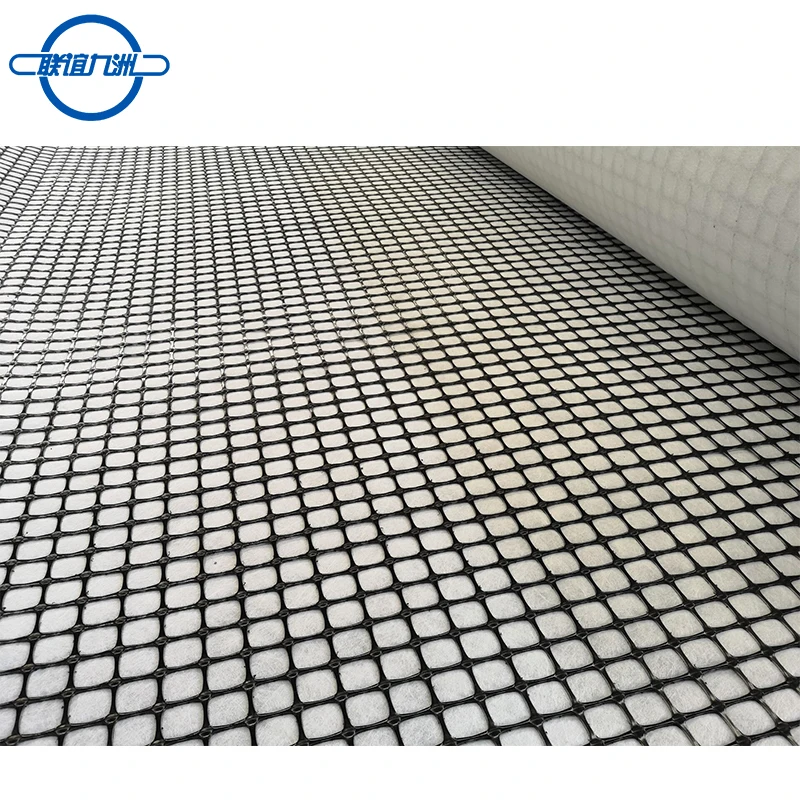

Geogrid geocomposite non-woven geotextile slope protection

Product introduction

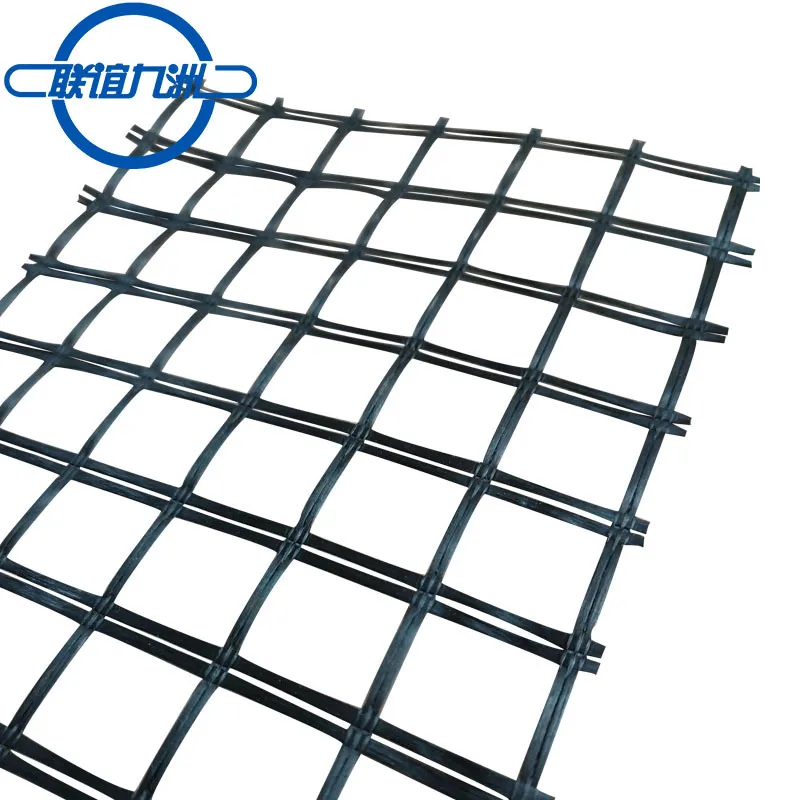

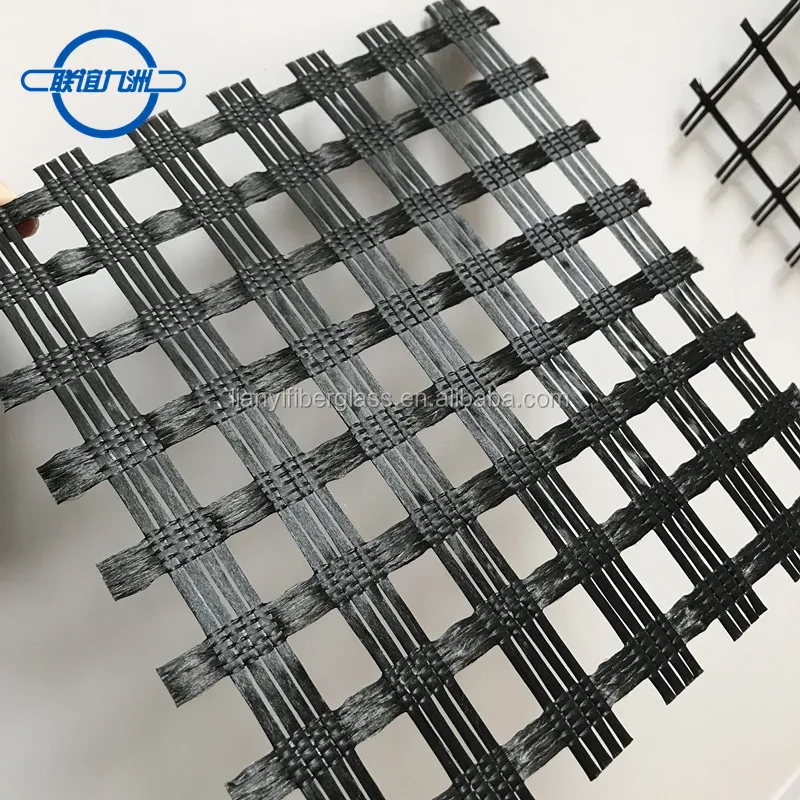

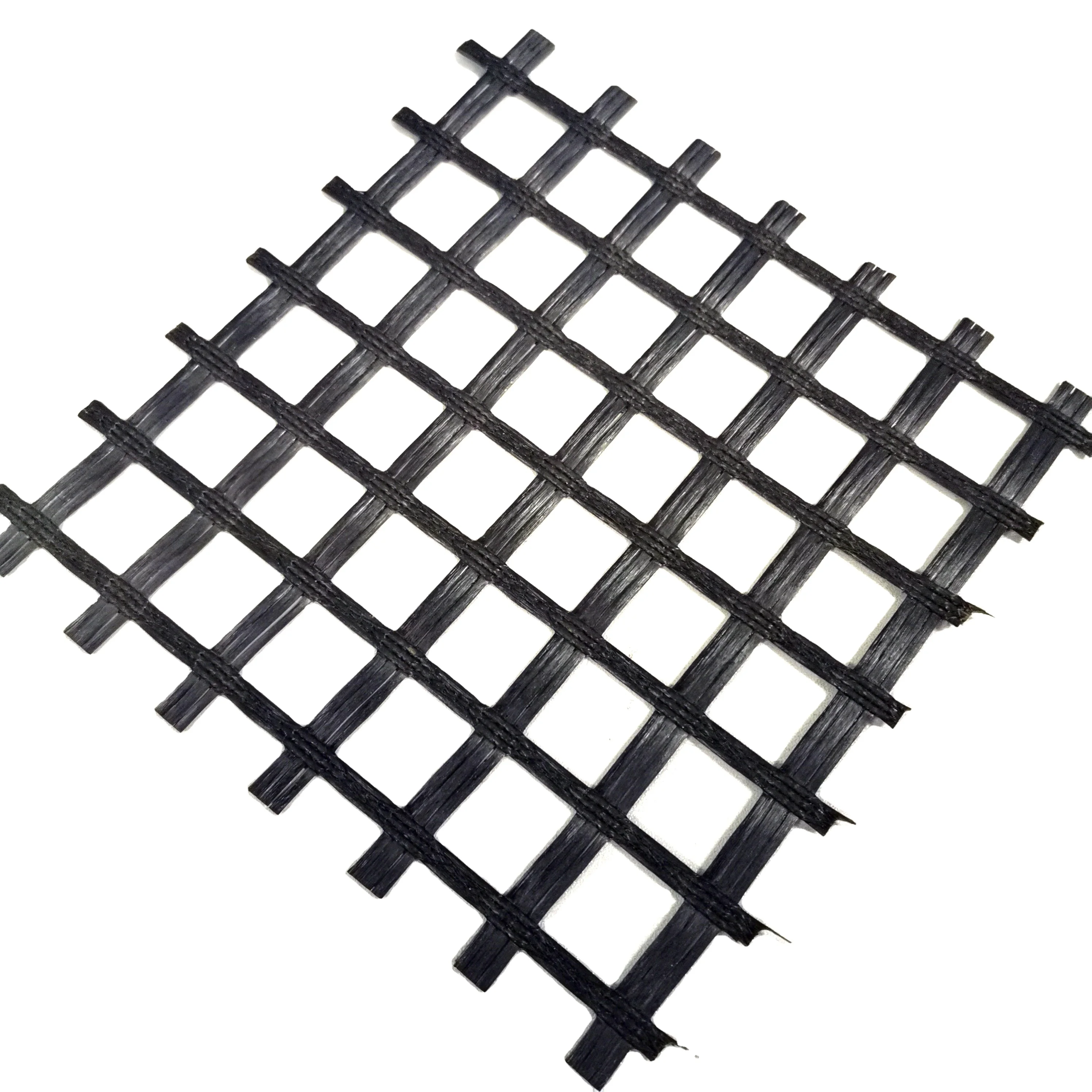

BIAXIAL GEOGRID COMPOSITER is a composite made of bi-axial polypropylene (PP) geogrid, heat bonded to a long fiber non-woven polyester geotextile that acts as a filter and soil separator. This geogrid is manufactured using a punching and drawing process whereby the polypropylene sheet is stretched in two directions, machine (longitudinal) and cross-machine (transverse). The result is a monolithic and isotropic geogrid with thick and wide ribs, thick integral nodes, and uniform square apertures. Engineered to be mechanically and chemically stable in aggressive soil environments, THIS-GEOCOMPOSITE allows sub-base drainage to help maintain structural stability, and is very effective in keeping expensive imported material from being contaminated by migration of fines from the saturated base soils.

| TESTED PROPERTY | TEST METHOD | UNIT ENGLISH(METRIC) | VALUE ENGLISH(METRIC) | |

| BI-AXIAL GEOGRID | MD | XD | ||

| Carbon Black Content | ASTM D 4218 | % | 2.0 | |

| Ultimate Tensile Strength{1} | ASTM D 6637 | lbs/ft(kN/m) | 1645(24.0) | 1645(24.0) |

| Tensile Strength at 2% strain{1} | ASTM D 6637 | lbs/ft(kN/m) | 720(10.5) | 720(10.5) |

| Tensile Strength at 5% strain{1} | ASTM D 6637 | lbs/ft(kN/m) | 1343(19.6) | 1343(19.6) |

| Junction Efficiency{2}{3} | GRI-GC2 | % | >95 | >95 |

| Flexural Rigidity{1} | ASTM D 7748 | mg-cm | 1000000 | |

| Aperture Stability{2}{4} | US.COE | m-N/deg | 0.65 | |

| Minimum Rib Thickness | Callipered | inch(mm) | 0.07(1.7) | 0.05(1.3) |

| Aperture Size{2}{5} | Nominal | inch(mm) | 1.33(34.0) | 1.22(31.0) |

| GEOTEXTILE | ||||

| Raw Material | Polyester, Continuous filament, needle punched | |||

| Ultimate Tensile Strength{1} | ASTM D 4595 | lbs/ft(kN/m) | 781(11.4) | 781(11.4) |

| Grab Strength{1} | ASTM D 4632 | lbs(kN) | 128(0.57) | |

| Trapezoidal Tear{1} | ASTM D 4533 | lbs(kN) | 56(0.25) | |

| Elongation at Ultimate{2} | ASTM D 4595 | % | 60 | 60 |

| CBR Burst Strength{1} | ASTM D 6241 | lbs(kN) | 540(2.4) | |

| Permeability | ASTM D 4491 | cm/sec | 0.41 | |

| Apparent Opening Size O9S | ASTM D 4751 | mm | 0.12 | |

| Mass Per Unit Area{2} | ASTM D 5261 | oz/yd2(g/m2) | 6.0(200) | |

| TYPICAL ROLL DIMENSIONS | ||||

| Roll Width | ft(m) | 12.79(3.9) | ||

| Roll Length{6} | ft(m) | 164.04(50.0) | ||

NOTES:

{1}Minimum Average Roll Values(MaRV-calculated as (mean minus 2X standard deviation)

{2}Average

{3}Junction efficiency is defined as junction strength divided by multi-rib strength

{4}Resistance to in plane rotational movement measured at an applied momen = 2m-N{20kg-cm} in accordance with US Army Corps of Engineers methodology for the measurement of Torsional rigidity

{5}Aperture tolerance: within+/-10% coefficient of variance

{6}Custom length orders can be accommodated.

Похожие товары

Георешетка из стекловолокна

Полипропиленовая Двухосная пластиковая георешетка стабилизация почвы цены на георешетку/георешетка с высокой прочностью разрыв

Сетка из базальтового волокна/георешетка стекловолокна

Биаксиальная георешетка PP по заводской

Высокая прочность на растяжение стекловолокна геосетка цены для асфальта тротуара

ПП Двухосная георешетка цены

Битумное покрытие асфальт дорожного армирования стекловолокна геосетка

Новые поступления

Новинки товаров от производителей по оптовым ценам