Электрическая паяльная машина автоматическая SMT линия сборки волновая подающий конвейер

- Категория: >>>

- Поставщик: Shenzhen Yuanzhi Automation Technology Co. Ltd.

Сохранить в закладки 1600167579916:

Описание и отзывы

Характеристики

soldering machine professional Infrared bga preheating smd rework station for PCB

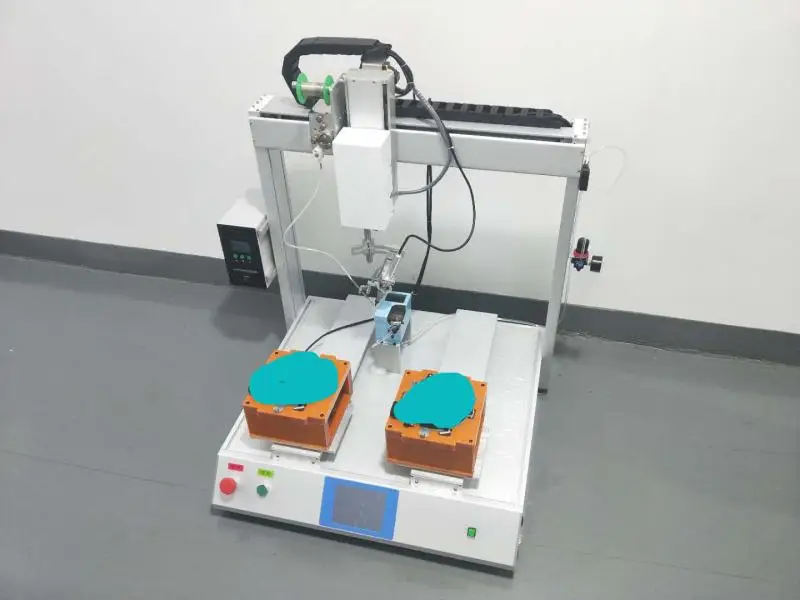

Automatic Soldering Machine

Model: YS-HX331

Application:

Integrated circuit boards, connectors, full range of PCB Board, LED aluminum plate, etc.

Specifications:

Model | YS-HX331 |

Voltage & Frequency | 220V/110V, 50Hz/60Hz |

Power | 300W |

Heating method | High-power constant temperature soldering iron |

Temperature | 150-450℃ |

Welding head quantity | 1 |

Air supply | 4-6KG |

Air source | Max 0.99MPa Clean oil-free dry air |

Solder feeding amount | 0.01mm |

Repeat accuracy | ±0.03mm |

Control system: | Four-axis motion control system, independent research and development |

Display | 5.7 inch touch display screen |

Language | English |

Weight | 63KG |

Size | L671×W551×H612mm |

Features:

l X Route: 300mm; Y Route: 300mm; Z Route150mm;

U Route: 360 degree rotation

l X Speed: 500mm/second Y Speed: 500mm/ second; Z Speed: 400mm/ second

U Speed: 360 degree/ second

l Support 2 heads: supports a maximum of 4 weld heads (Direction is fixed)

l Operator interface: 5.7 inch touch display screen, integrated structure, and Chinese/English operation, Easy to set up.

l Can draw: Points, lines, circles, and arcs. Spot welding or continuous welding.

l Input mode: teach or file input, DXF, PLT and other formats

l Repeat accuracy ±0.03m

l Control system: four-axis motion control system, independent research and development

l Rotation: stepper motor & linear rail & synchronous belt

l Maximum load X/Y/Z 10KG/10KG/5KG

Advantages:

1. Chinese/English input, easy to learn and easy to understand, without an external guidance device, more convenient, simple and high speed precision.

2. With points, lines, arcs, circles, irregularly curved continuous input procedures and any position welding.

3. Solder feeding amount is adjustable. With temperature adjusting function

4. To edit the continuous and rapid spot, set change interval to achieve repeated welding solution, increasing operational efficiency.

5. High speed precision stepping motor makes location more accurately

6. Adjust the temperature and time and solder feeding speed, control the amount of feeding solder, meets high quality welding

7. According to a client's product, you can choose to assemble multiple spot welding, more suitable for the arrangement of standard products.

8. Can preview edit tracks and adjust accordingly.

9. Welding path can be called at any time, weld track store multiple files, no need repeated edit.

10. Equipped with computer controlled motion, software programming, multiple operations can be realized.

More than 20 years Robot Factory

----Purchase Guidance

If not sure which one is your best choice within the budget, please provide the details or samples to us. We will provide the best solutions and machines.

As one of leading manufacturer in China, we offer factory price and very thorough quality check before

----After Sale Services

We provide lifelong support after sale including operation guidance, parts replacement and maintenance support. Just feel free to contact us.

----Technology Consultation

Any question about wires, cables, machinery, and even the production line please feel free to contact us. We can provide reasonable budget and suggestions.

----OEM Services

We provide OEM services.

Похожие товары

Лучший выбор, популярный роскошный разумный шкаф для винного бара из нержавеющей стали по разумной цене

Креативные офисные канцелярские товары, шариковая ручка в металлической форме с индивидуальным логотипом, Подарочная цветная рекламная ручка в виде собаки шара-пея

Reptizoo IN003H-35W 905x145x16 мм разведение рептилий стеллаж для выставки товаров нагревательная доска для IN003 разведение стеллаж для выставки товаров для амфибии и домашних животных

10 дюймов 21 в электрическая литиевая обрезная цепная пила Беспроводная деревообрабатывающая мини-батарея бензопила

Повязка на голову с цветами и розами для фотографирования новорожденных девочек

2021 мужская одежда 100 мерсеризованный хлопок Органическая футболка с принтом логотипа на заказ Мужская городская футболка

1000 шт. просто нужно 80 долларов США печать логотипа на заказ дешевая высечка индивидуальной формы белая ПВХ наклейка

Новые поступления

Новинки товаров от производителей по оптовым ценам