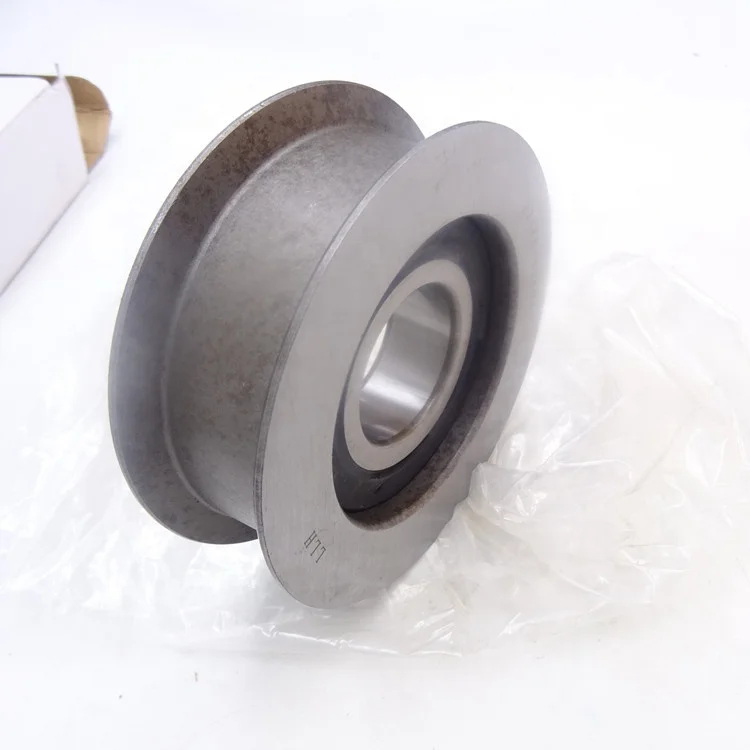

234A8 43501 подшипник мачтового подшипника вилочного погрузчика запчасти для вилочный погрузчик

- Категория: >>>

- Поставщик: Jinan Maolei Bearing Co. Ltd.

Сохранить в закладки 1600173710439:

Описание и отзывы

Характеристики

Item | Specifications |

Model | 234A8-43501 |

Material | GCr15 |

Bore size | 40mm |

Outer diameter | 98mm |

Weight | 1.42kg/1 Piece |

Precision Grade | P0-P6 |

Seal type | Open, ZZ, 2RS |

Inner clearance standards | C2, C0, C3, C4, C5 |

Vibration | Z1V1, Z2V2, Z3V3 |

Cage | Stamping steel, brass solid cage |

Application | Automobile, tractor,agriculture machine, textile machine, etc. |

Packaging | Original Paper box |

forklift mast roller bearings are used in a very important metal parts, forklift truck work in the hair bearing play an irreplaceable role.

Industrial handling vehicles are widely used in ports, railway stations, airports, freight yard, workshop, warehouses, distribution centers and distribution centers, and access to the cabin, carriages and containers for loading and unloading pallets, handling operations.

Fork Lift Bearings are a blend of simple design and assembly. A pillow bearing has deep groove ball bearing, which is sealed on both sides and a spherical diameter on the outside with housing. The housing is either a casting or a sheet metal stamping. The Fork Lift Bearings are resistant to temperatures, dimensionally accurate and have high functionality.

forklift mast roller bearings lubrication

40*90*29mm bearing lubrication, first open the cover and watch to check the release bearing wear, if they are recognized bearing no damage or wear is not overrun, remove the clutch pedal adjustment mandrel release bearing and its seat back to the last position,butter filling to the bearing hole with a needle nose grease gun until the bearing oil spill, then slightly turn the bearing oiling again, repeat the above work, a little butter until around the bearing has an overflow, and then the bearing rotation observed oilIf you feel the the bearing rotation resistance,that bearings have been filled with butter. Then clear separation of a small amount of butter, and re-adjust the separation bearing position throughout the bearing seat overflow

forklift mast roller bearings Precautions

1, To keep the forklift bearing its surroundings clean

Even if the the invisible smile dust into the forklift bearings will increase bearing wear, vibration and noise.

2, Using the installation to be carefully

Not allow powerful punch forklift bearing, does not allow a direct hit with a hammer, and not allowed to pass through the rolling pressure.

3, The use of appropriate, accurate installation tools

To make use of a special tool, and tried to avoid using something like cloth and short fiber.

4,To prevent the corrosion of forklift bearings

Handle forklift bearing directly to wash hands sweat, and coating quality mineral oil and then operate, with particular attention to anti-rust during the rainy season and summer.

| Bearing MODEL | Specification (mm) | ||

| inside diameter | outside diameter | outside height | |

| 180705C | 25 | 70 | 23 |

| 180705D | 25 | 78 | 22 |

| 180705K | 25 | 80 | 22 |

| 180706K | 30 | 91.5 | 24 |

| 180707K | 35 | 102 | 25.5 |

| 180708K | 40 | 109.7 | 32 |

| 180709K | 45 | 119 | 29 |

| 10310RT | 50 | 123 | 40 |

| CG92310T | 50 | 123 | 34 |

| 780310 | 50 | 130 | 40 |

| 10311T | 55 | 151.5 | 45 |

| 80611K5T | 55 | 149 | 45 |

| 10311TK | 55 | 151.5 | 45 |

| 30311XT/30311MT | 55 | 151.5 | 45 |

| 10220D | 100 | 205 | 52 |

| 10724 | 120 | 245 | 66 |

| 80511Y/980811 | 55 | 121/119 | 34 |

| 980811NT | 55 | 119.2 | 34 |

| 10811S | 55 | 118.5 | 34 |

| 980811M | 55 | 118.8 | 34 |

| 80511K2T | 55 | 120 | 34 |

| 80511K1T | 55 | 119.6 | 34 |

| 80511YET | 55 | 119/117 | 34 |

1.High speed, High Precision, Low Noise, Long Service Life

2.Wide Array of Applications

3.Large Inventories

4.Small order accept

5.Competitive Prices and High Quality

6.Various Brands

7.Require little maintenance

8. OEM is supported

9. Our company insists on the "quality first, credit first" business ideas and our product specification is well-founded. We have a good reputation in the international market by our perfect service and sufficient supply.

Jinan Maolei Bearing Co., Ltd is a manufacturer and trader specialized in the research, development and production of bearings. is located in the "Spring City" Jinan, with convenient transportation.

The core products of Jinan Maolei bearing Co,.Ltd have a variety of bearings ranging from deep groove ball bearings, self-aligning ball bearings, self-aligning roller bearings, wheel hub bearings, linear bearings, pillow block bearing, ceramic bearings, plastic bearings, cylindrical roller bearings, angular contact ball bearings, tapered roller bearings, thrust ball bearings, thrust roller bearings and needle roller bearings to spherical plain bearings and other products. All of our products comply with international quality standards ISO 9001 and are greatly appreciated in a variety of different markets throughout the world.

We insist on the philosophies of "integrity" and "pragmatic & win-win business". We also adhere to the "people-oriented" and "advancing" enterprise spirit . "Quality first and customers utmost" is honored as our enterprise concept.

Q: Are you trading company or manufacturer ?

A: We are the manufacture of bearings for more than 20 years, "Quality is our culture".

Q: How long is your delivery time?

A: Generally it is 1-3 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: What causes bearing noise?

A: Bearing noise is a function of both the bearing and the way it is used. Some external factors that affect bearing noise include lubricant type, excessive bearing load, and improper installation. Once the abnormal noise occurred, you can contact our engineers, we will help you find the reasons and provide the appropriate solutions.

Q: What is your terms of payment ?

A.100%T/T

B.30%T/T in advance,70% aganist copy of B/L(For large order)

C.Western Union

D.Paypal

Похожие товары

Регулируемая муфта прицепа, рама, муфты прицепа, муфта на гусиную шею

Грузовик для транспортировки свиней FOTON Auman, 3 слоя, 200-300 шт., распродажа

Новый дизайн, имитация пальмового бонсай, украшение для сада, офиса, зеленое растение с соломенным цветочным горшком

Оригинальный ЖК-модуль DV150X0M-N10 BOE, разрешение 1024*768, 15-дюймовая ЖК-панель для цифровых вывесок и промышленности

Для 2017 2018 2019 TOYOTA VIOS YARIS SEDAN комплект кузова автомобиля передняя губа задний бампер диффузор боковые юбки

Автоматический комплект для впрыска топлива, эмулятор газа СПГ, эмулятор газа с 4 цилиндрами, эмулятор газа

SC/APC-SC/APC Simplex Singlemode SX SM волоконно-оптический кабель, Соединительный шнур и перемычка для оптоволокна к X в телекоммуникациях

Новые поступления

Новинки товаров от производителей по оптовым ценам