Дробилка кукурузного стебля | Измельчитель пшеничной соломы

- Категория: >>>

- Поставщик: Zhengzhou Huaqiang Heavy Industry Technology Co. LtdZhengzhou Ltd

Сохранить в закладки 1600176612142:

Описание и отзывы

Характеристики

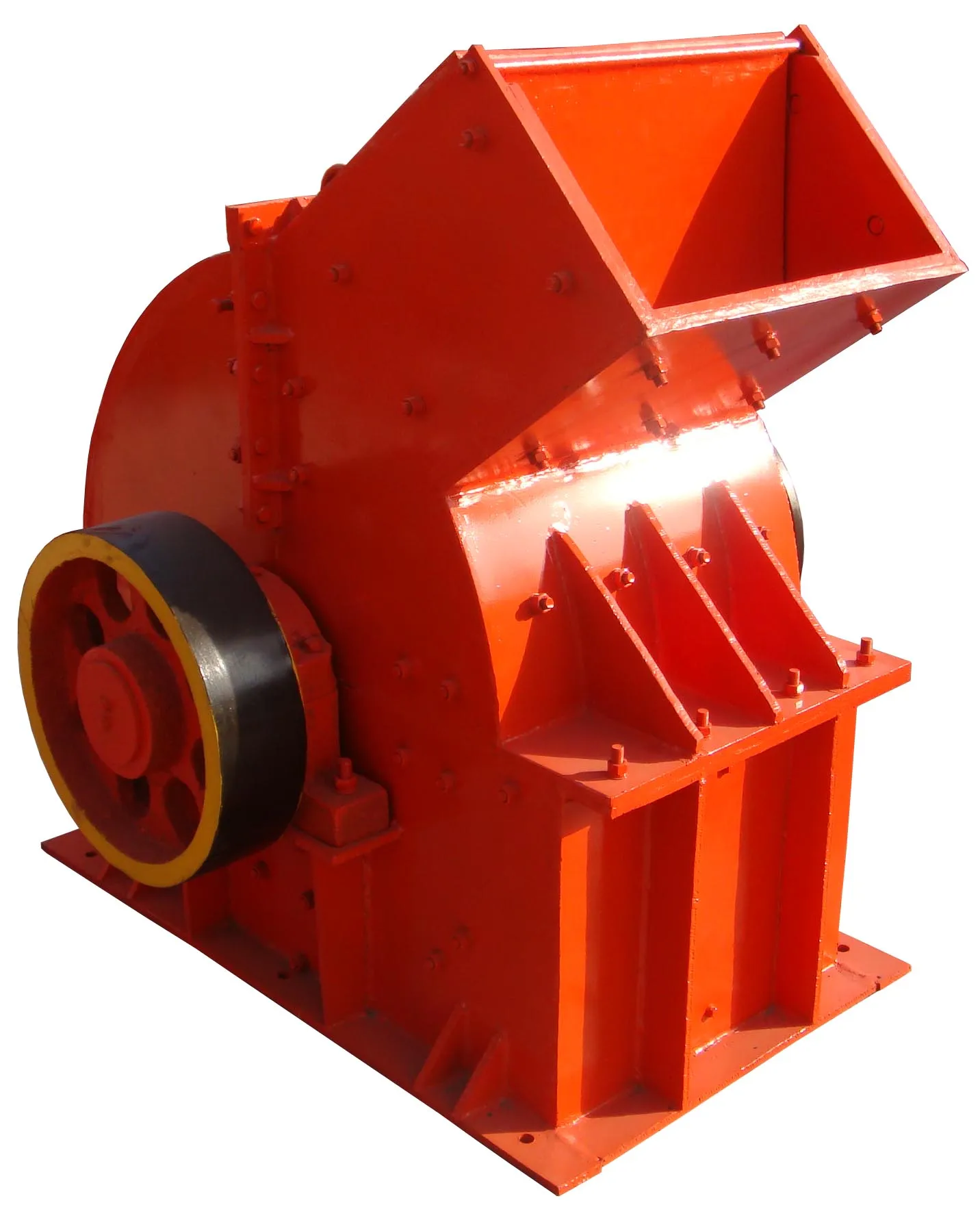

corn stalk crusher | wheat straw grinder | paddy stem microniser

Characteristics of corn stalk crusher | wheat straw grinder | paddy stem microniser

1. The straw crop crusher has reasonable structure design, reliable quality, simple structure, convenient operation, small size, less land occupation, labor saving and power saving.

2. The pulverizer has a automatic control heating device, which can randomly adjust the dry and humidity of the material, ensure the stability of the discharging molding and improve the working efficiency.

3. The main parts of the crusher are made of wear-resistant materials which have been specially treated, so they can be continuously pressed for production and are durable.

Product usage of corn stalk crusher | wheat straw grinder | paddy stem microniser

This pulverizer machine is especially suitable for crushing various biomass raw materials (corn straw, wheat straw, cotton stalk, straw, rice husk, peanut hull, corn cob, branch, leaf, sawdust) and other crop raw materials or wood factory waste.

| Model | Power(kw) | Capacity(t/h) |

| 9Z-0.5 | 3 | 0.5 |

| 9Z-1.2 | 3 | 1.2 |

| 9Z-2.5 | 5.5 | 2.5 |

| 9Z-5.0 | 5.5 | 5 |

| 9Z-8.0 | 7.5 | 8 |

| 9Z-10.0 | 15 | 10 |

| 9Z-12.0 | 18.5 | 12 |

| 9Z-30.0 | 37 | 30 |

Company Information:

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. specializes in the production of fermentation compost turner machine, fertilizer granulator, fertilizer crusher and other organic fertilizer machines. We also provide a complete set of organic fertilizer production process, npk fertilizer manufacturing process, biofertilizer production process, BB fertilizer production equipment. We have been stepping forward the pace of machine progress, hoping to use the best fertilizer equipment to feed back our users!

Product packaging:

In order to avoid mechanical damage, we use wooden boxes or containers, and fix the machine inside to ensure the integrity of the machine. To ensure that the products ordered by customers can be delivered on time, and the finished products are being delivered to the customer's production site.

processes flow:

We have rich experience in design and development and excellent team service. We have gathered a group of senior fertilizer equipment design professionals, who can customize different plant design schemes and equipment schemes according to the actual situation of customers. We have excellent production and processing capacity and fast logistics and distribution capacity, in the quality of equipment and supply capacity has been in the top market. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

Successful cases:

We make fertilizer equipment and production line for our customers. After years of survival experience, our products have a great influence on the market. If you have any questions, please contact our online customer service at any time.

If you have any question when you contact or before place an order to us, please first check the below information for reference. You can find information that can help you decide whether your product or related accessory needs service, and see what service options are available to you.

1. Which countries are your products sold to?

The products of Zhengzhou Huaqiang Heavy Industry Co., Ltd. have been exported to more than ten countries and regions such as the United States, Germany, Japan, Russia, Australia and countries in the Middle East and Africa.

2. How to pack the product?

For the sake of safety, we use wooden cases or containers to avoid damage to the products.

3. How long is the delivery time of the product?

Usually, our delivery time is 25 to 30 days.

4. What is after-sales service?

a. Free assignment of professional after-sales service personnel, arrived at the site to guide the customer installation and commissioning.

b. Train operators on site.

c. After the installation of the complete set of equipment, technical personnel shall be left to assist the customer in field production for free until the customer is satisfied.

5. With what payment?

Our payment methods include L/C, T/T, Western Union, MoneyGram.

Похожие товары

Аллювиальный Золотой скруббер барабан Золотая сухая шайба полностью полная система мобильного аллювиального золотого земснаряда с заноской

Лидер продаж Высококачественная переработка песка центробежный концентратор в мобильной тележке для обработки Аллювиального золота с заносом

Высокоэффективная Мобильная аллювиальная Золотая моечная установка мойка машина для добычи золота

Двухступенчатая мобильная дробильная станция Y2shpc22l завод по дроблению камня

36 24 Pe250 400 Coal Primary Stone Crusher for

Low Price Metal Crusher Production Line Mobile Mini Granite Glass Rock Ores Hammer Crushing Machine Stone

Мобильная мини щековая дробилка с дизельным двигателем/Портативная для продажи

Новые поступления

Новинки товаров от производителей по оптовым ценам