Трехфазная декантерная центрифуга для угля и угольной смолы

- Категория: >>>

- Поставщик: Jinhua Shenzhou Centrifuge Co. Ltd.

Сохранить в закладки 1600183084751:

Описание и отзывы

Характеристики

LW Horizontal Decanter Centrifuges

Introduce Coal Chemical Industry---------------------- ----------------

Coal chemical industry refers to the process of converting coal into gas, liquid, and solid fuels and chemicals through chemical processing. It mainly includes coal gasification, liquefaction, dry distillation, tar processing, and calcium carbide acetylene processing. Coal chemical processing. The chemical structure of organic matters in coal takes the condensed nucleus of aromatic (mostly) as a unit core, which is of bridged linkage and has a macromolecular structure with various functional groups. Through thermal and catalytic processing, coal can be converted into various kinds of fuels and chemical products.

Advantage-------------------------------------------------------------- ---------

Coal tar is a dark brown viscous liquid produced during the dry distillation of coal, referred to as tar; the black brown produced during the coal dry distillation is related to a viscous liquid reeking of a pungent odor, with a yield accounting for about 3~4% of the dry coal;

The crude tar is recovered from the coal gas produced in the coking process that is sprinkled with circulating ammonia and condensed in a primary cooler. It contains large water, about 4%, sometimes 8~10%;

Main characteristics------------------------------------------------- --------

The heavy liquid phase separated by the centrifuge can adopt two different liquid discharging modes.

2.High-performance sealing material can effectively avoid the swelling failure of ordinary rubber parts;

3.The coke button in the coal tar is an important factor affecting the stability and service life of the centrifuge due to abrasion.

The centrifuge features high separation efficiency, compact structure, and continuous operation. The diameter of the separated particles can be reduced to 2 μm.

1. The solid content (toluene insoluble matter) in the treated coke button is more than 45%, which can easily optimize the clarification of liquid and the dryness of solids.

2. Tar quality after separation: aqueous ammonia content: <2.5%; tar content: ≥97%; solid content (> 100 μm): <0.3%

3. After separation, the tar in the aqueous ammonia: ≤ 4g/L

Technical parameter -------------------------------------------------- ------

| Model | Diameter(mm) | Lenght(mm) | Max speed | L/D ratio | G-force | Capacity(m3/h) | Main motor power(Kw) | Weight(kg) | Dimension(mm) |

| LW250*1000 | 250 | 1000 | 5000 | 4 | 2722 | 0.5-5 | 7.5 | 950 | 2120*1250*680 |

| LW300*900 | 300 | 900 | 4200 | 3 | 2964 | 1-6 | 11 | 1160 | 2150*1300*900 |

| LW300*1200 | 300 | 1200 | 4000 | 4 | 2784 | 2-6 | 11 | 1350 | 2450*1300*900 |

| LW355*1160 | 355 | 1160 | 3600 | 3.3 | 2576 | 2-8 | 15 | 1400 | 2470*1350*830 |

| LW355*1460 | 355 | 1460 | 3600 | 4 | 2576 | 2-10 | 15 | 1800 | 2750*1350*830 |

| LW400*1200 | 400 | 1200 | 3200 | 3 | 2294 | 3-12 | 18.5 | 1800 | 2730*1600*1080 |

| LW400*1600 | 400 | 1600 | 3000 | 4 | 2016 | 3-15 | 22 | 2000 | 3130*1600*1080 |

| LW450*1800 | 450 | 1800 | 2800 | 4 | 1976 | 4-25 | 37 | 2500 | 3320*1700*1130 |

| LW500*2000 | 500 | 2000 | 2800 | 4 | 1750 | 5-35 | 45 | 4000 | 3520*1800*1170 |

| LW530*1855 | 530 | 1855 | 2600 | 3.5 | 2006 | 5-38 | 55 | 4680 | 3885*1350*1600 |

| LW530*2120 | 530 | 2120 | 2400 | 4 | 1709 | 5-40 | 55 | 4800 | 4150*1350*1600 |

| LW550*2000 | 550 | 2200 | 2800 | 4 | 2414 | 6-40 | 55 | 5700 | 4570*1380*1600 |

| LW650*1950 | 650 | 1950 | 2200 | 3 | 1761 | 6-45 | 75 | 5000 | 4840*1510*1720 |

| LW650*2600 | 650 | 2600 | 2000 | 4 | 1456 | 6-65 | 90 | 6000 | 5490-1510*1720 |

| LW720*2160 | 720 | 2160 | 2000 | 3 | 1612 | 7-80 | 120 | 6000 | 5200*1600*1800 |

| LW720*2880 | 720 | 2880 | 2000 | 4 | 1306 | 7-90 | 120 | 8000 | 3100*1600*1800 |

| LW800*2400 | 800 | 2400 | 1800 | 3 | 1451 | 20-100 | 150 | 12000 | 5820*2000*1300 |

| LW800*3200 | 800 | 3200 | 1800 | 4 | 1451 | 20-120 | 150 | 13000 | 7100*2000*1300 |

Technical service:

- technical direction when installation, debugging

- training for operation and maintain worker

Training:

- separator working principle and structure

- operation regulation and attention

- machine maintains

Shenzhou Centrifuge has been developing and manufacturing centrifuges for nearly 80 years, and is one of the Chinese leading manufacturer. Shenzhou Centrifuge has more experience and expertise than any other separator manufacturer when it comes to applying and using decanter centrifuge for the purpose of continuous separation.

Похожие товары

Роскошный модный кожаный ремень для конного спорта с пациентной кожей на носовом ремешке и анатомической носовой ленте и короне

Горячая Распродажа, силиконовая резиновая кухонная сушилка для посуды

Трехколесный распашной скутер, трехколесный скутер speeder.

Оптовая продажа, принт с персонажами мультфильмов, корсажная лента бутик 3 дюймов корсажная лента

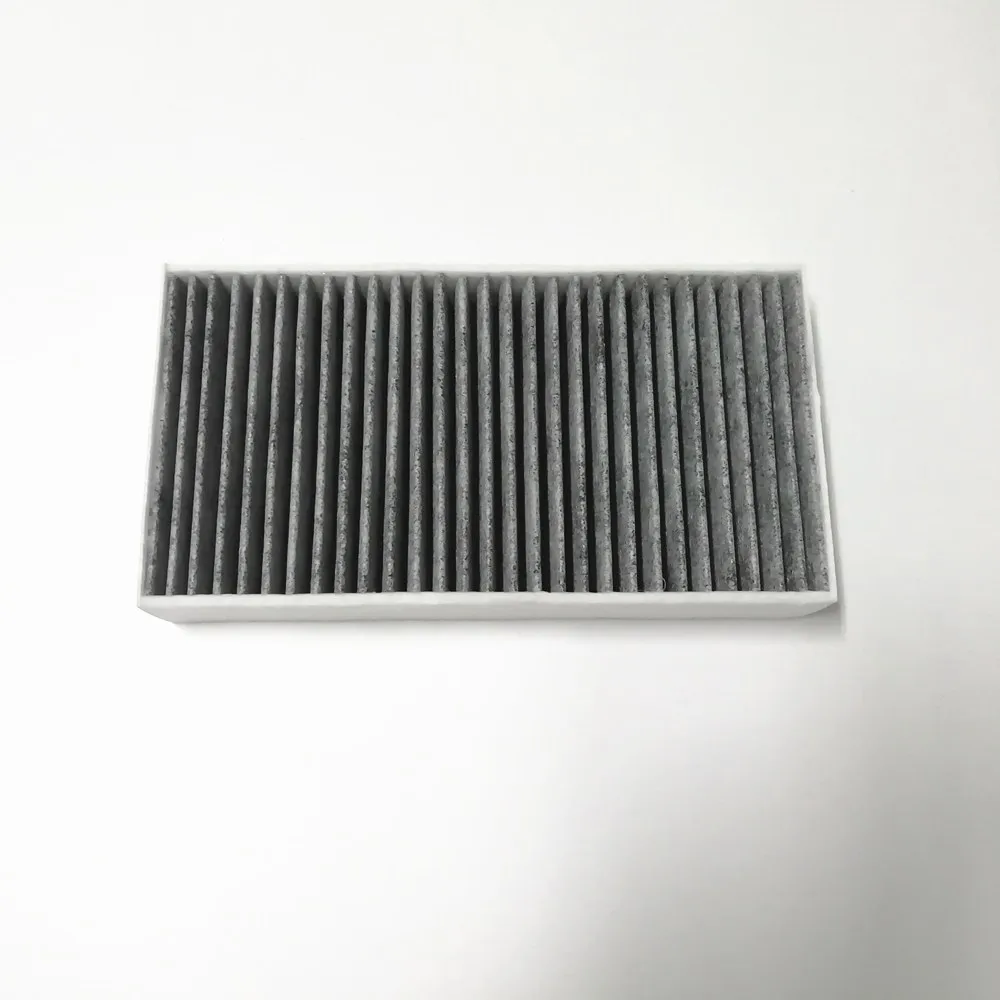

Автомобильный воздушный фильтр салона 1541456 1566997 1594615 8V5118D543AA

Высококачественное сырое/рафинированное масло канолы/Рапсовое Масло Премиум-качества

Различные типы перевернутых барабанов паровой ловушки из нержавеющей стали

Новые поступления

Новинки товаров от производителей по оптовым ценам