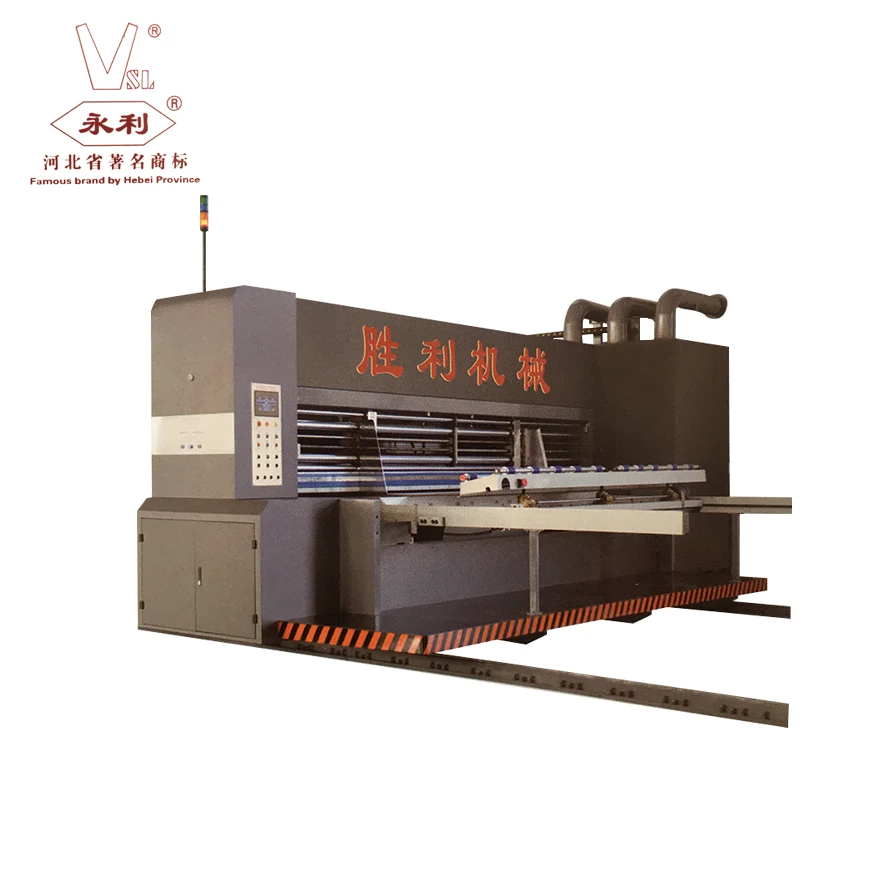

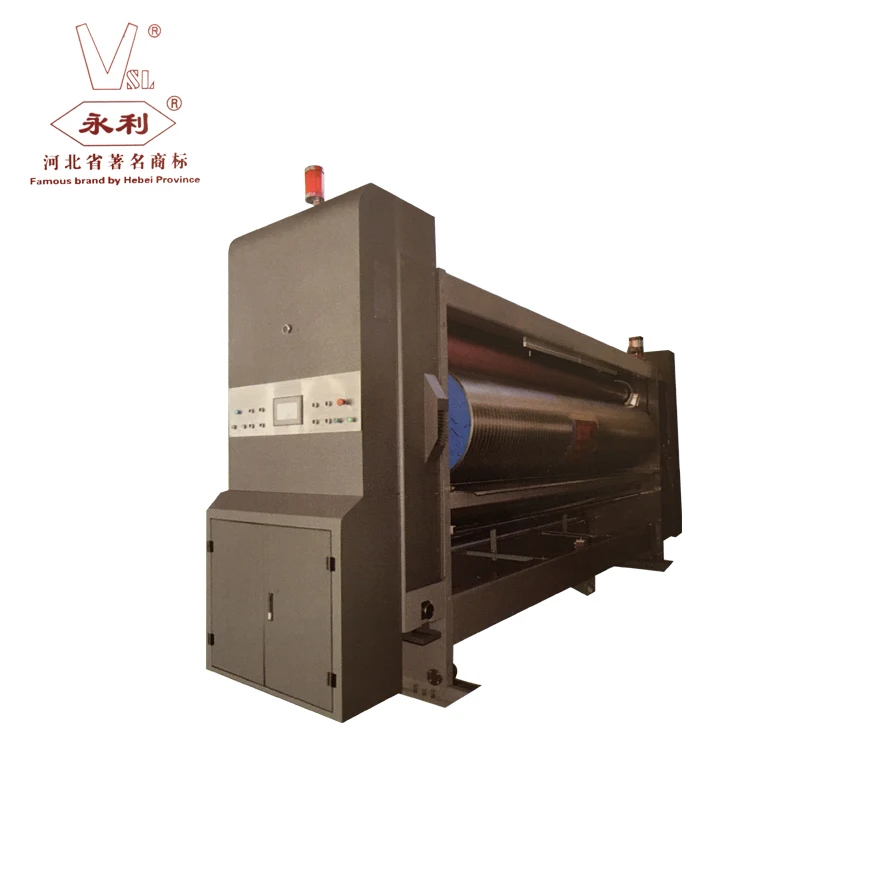

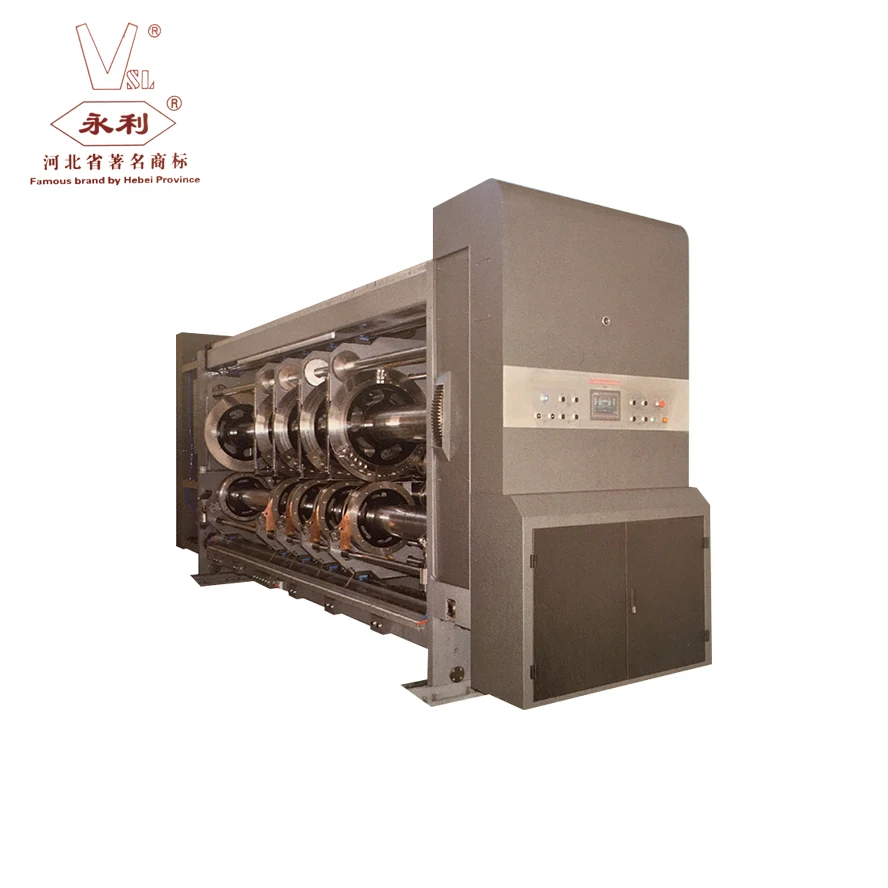

YKW2500*2500 lead edge feeder printing slotting die cutting machine carton

- Категория: >>>

- Поставщик: Hebei Shengli Paper Chest Equipment Manufacturing Co. Ltd.

Сохранить в закладки 1600187815400:

Описание и отзывы

Характеристики

FEATURES AT A GLANCE

Function and characteristics

1、All of the electric appliances of the whole machine are of the brand of Schneider made in France.

2、Adopt leading edge feeding system.

3、Adopt helical gear driving,the gear are made of high frequency quenching and grinding material.

4、All of the transmission rollers are made of high-quality steel with abrasive grinding hard chrome plated surface.

5、The gears adopt spray circular lubricating.

6、The machine is equipped with PLC、touching screen,multi-function control,frequency converter,accurate and reliable.

7、Automatically reset,automatically correct plate.

8、Modular design,multi-color printing units can be combined in any way.

Printing unit

Slotting unit

Die cutting unit

PRODUCT CONFIGURATION

No. | Item | YKW2500*2500 | YKW2500*3000 | YKW2500*4000 | YKW2500*4600 |

1 | Width of inside machine | 2920mm | 3420mm | 4420mm | 5020mm |

2 | Design speed | 100pieces/min | 100pieces/min | 100pieces/min | 100pieces/min |

3 | Maximum feeding size | 2400*2500mm | 2400*3000mm | 2400*4000mm | 2400*4600mm |

4 | Minimum feeding size | 650*900mm | 650*900mm | 650*900mm | 650*900mm |

5 | Maximum printing size | 2400*2400mm | 2400*2900mm | 2400*3900mm | 2400*4500mm |

6 | Printing precision | ±0.5/0.5/0.75 | ±0.5/0.5/0.75 | ±0.5/0.5/0.75 | ±0.5/0.5/0.75 |

7 | Standard plate thickness | 7.2mm | 7.2mm | 7.2mm | 7.2mm |

8 | Printing paperboard thickness | 5-15mm | 5-15mm | 5-15mm | 5-15mm |

9 | Minimum slotting space | 320*100*320*100mm | 320*100*320*100mm | 320*100*320*100mm | 320*100*320*100mm |

10 | Maximum slotting depth | 620mm | 620mm | 620mm | 620mm |

11 | Printing roller axial adjusting | ±10 | ±10 | ±10 | ±10 |

12 | Maximum die cutting size | 2400*2500mm | 2400*3000mm | 2400*4000mm | 2400*4600mm |

Feeding unit

1、Adopt five-axle leading edge feeding system,more accurate,thin and bend paperboard easy to be feeding in.

2、The paperboard can be fed continuously or by partition(equipped with counter)

3、Dust cleaning device,brush and fan to remove paper scraps on the paperboard surface to improve printing quality.

4、 The rear paper supporting board electric control forward and backward,speed up the setting.

5、 Main motor is equipped with starting protection device(the main motor cannot start operation when the machine is not locked)

Printing unit

1、 The printing roller is made of high quality steel,with grinding surface and hard chrome plating.

2、 Balance correction,smooth operation.

3、 Loading and unloading printing plate,foot switch electric control positive and negative rotation.

4、 Printing phase is adjusted 360degrees by computer and electric digital control(both of operation and stop can be adjusted)

5、 The steel roller is wrapped with wear-resistant rubber. High special grinding of rubber roller,good ink transfer effect.

Slotting unit

1、 Slotted phase adjusting mechanism. Planetary gear construction.

2、 The slotting phase is adjusted 360 degrees by computer and electric digital control(Operation and stop can be adjusted).

3、 The position of pre-pressing line wheel, pressing line wheel and slotting knife block are shifted horizontally by computer and electric digital control.

Die cutting unit

1、 The upper and lower rollers are of high quality steel, with grinding surface and hard chrome plating.

2、 When the paper feeding is stopped, the rubber pad roller automatically rises to reduce unnecessary abrasion.

3、 Rubber pad roller cutting flat structure, keep the pad flat.Greatly improve the reuse of rubber pads.

Company photos

Successful Project

Project in Thailand

Project in India

Project in Russia

Certifications

SALES AND SERVICE NETWORK

SIMILAR PRODUCTS

FAQ

Похожие товары

Новинка игрушечный Гребной винт на

348,32 ₽ - 402,67 ₽

Высокоэффективные солнечные панели Longi 450 Вт 480 550 для розничной

15,53 ₽ - 17,75 ₽

Воздухонепроницаемые ПВХ тригонометрические конусные надувные треугольные буйки плавающие рекламные водные буи для водных видов спортаВоздухонепроницаемые

22 185,50 ₽

Большая 3-ярусная настенная полка из макраме богемная простая комнатная декоративная тканая

841,94 ₽ - 952,87 ₽

PowMr 1 целый набор вне сетки Солнечная энергия Система со слежением за максимальной точкой мощности инвертор зарядное устройство на солнечной батарее 5KW 10kw все в одном энергетической

98 503,62 ₽ - 110 816,58 ₽

Фигурка карлика украшения для интерьера декор гнома керамическое украшение домашнего

116,48 ₽ - 360,52 ₽

Высокое качество OEM шипучие таблетки для очистки зубных протезов персональное ежедневное Отбеливание Стоматологического

239,61 ₽ - 259,58 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Hantek щупы осциллографа автоматический Тестовый Кабель Ht30a Bnc к банану двойная Банановая головка многоцелевое автомобильное

3,10-3,44 $

Горячая распродажа ручная работа традиционная деревянная урна для домашних животных квадратная коробка золы собак и кошек персонализированная Лучшая цена

Промышленная серия CL Бесшумная цепь стальная зубчатая Фланцевая контактная звездочка соединяющая бесшумные цепи

1-1,50 $

Irdmco экологически чистый минималистичный прямоугольный деревянный ящик для хранения стеллаж поделок и детских игрушек Домашняя мебель гостиной

Технология сенсорных перчаток и аксессуары для детей от дождя холода M725132-334

1,07-1,40 $

GY6 6 Pin AC гоночный CDI для CG125 CG250 двигателя Dirt Pit Bike ATV Quad

Парик из синтетического волокна для косплея

9,85-12,66 $

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $