Сушилка для жидкости/катушка/агломератор

- Категория: Оборудование для сушки в кипящем слое >>>

- Поставщик: Sinoped International (Liaoning) Co. Ltd.

Сохранить в закладки 1600196760951:

Описание и отзывы

Характеристики

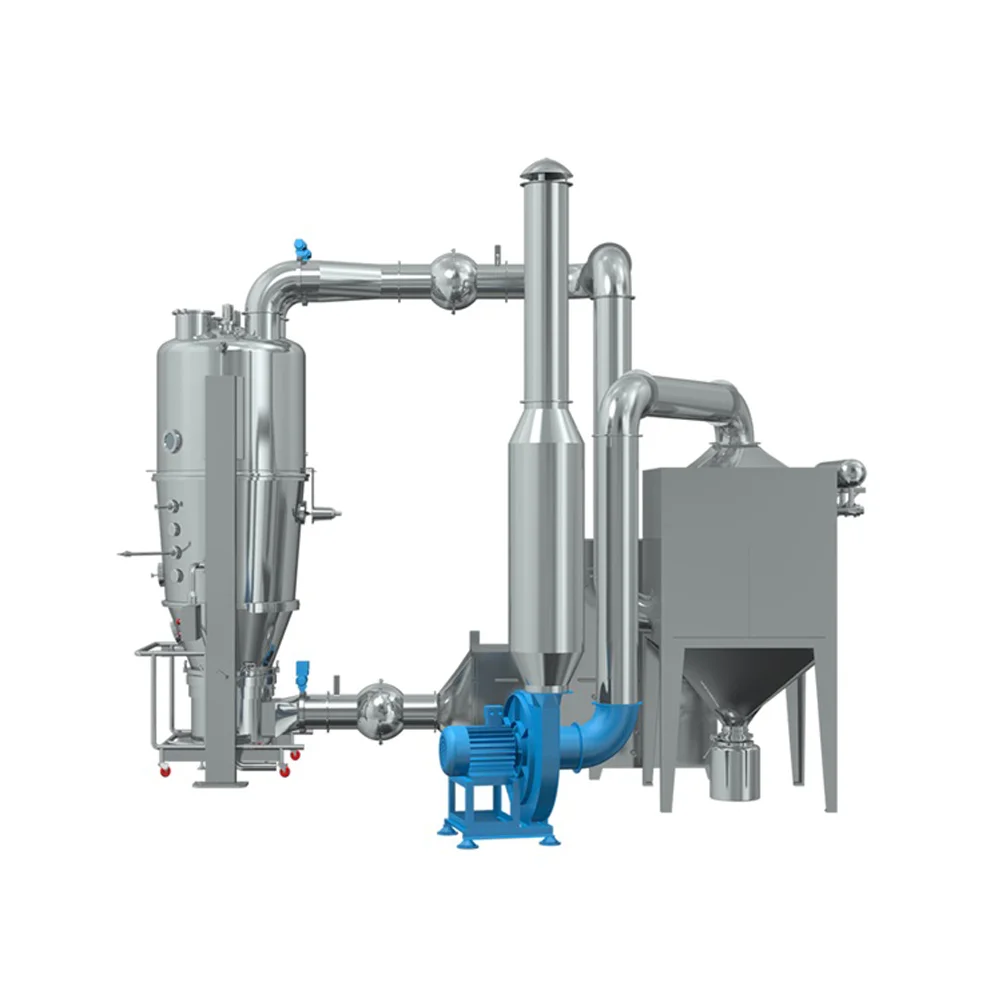

Fl-60 Multi-functional Fluid Bed Processor Machine With Wurster Coating

Product Description

The advantage of {SINOPED} 100KG FL Vertical Continuous Fluid bed dryer granulator for pharmaceutical rests with maintaining

evenness and recurrence of product quality, which reflects an ideal balance between production efficiency and product quality. In

the process of fluidization, the materials floats above the air, with surface in full contact with the heated air,and the materials therefore is evenly eated and reaches an ideal state for heat exchange thus to have a high efficiency. Configurated with proper spraying system and through further structural improvement, the fluid bed then becomes a multi-purpose processing facility in combined functions of drying, granulating, solution coating, and powder dressing.Final product usually instant solute granule.

evenness and recurrence of product quality, which reflects an ideal balance between production efficiency and product quality. In

the process of fluidization, the materials floats above the air, with surface in full contact with the heated air,and the materials therefore is evenly eated and reaches an ideal state for heat exchange thus to have a high efficiency. Configurated with proper spraying system and through further structural improvement, the fluid bed then becomes a multi-purpose processing facility in combined functions of drying, granulating, solution coating, and powder dressing.Final product usually instant solute granule.

Technical Data | ||||||||||||||

Model | 5 | 30 | 60 | 120 | 200 | 300 | 500 | |||||||

Capacity(kg/batch) | 5 | 30 | 30 | 120 | 200 | 300 | 500 | |||||||

Material yield rate(%) | >/=99% | |||||||||||||

Qualified rate(%) | <=85% | |||||||||||||

Container Volume(L) | 22 | 100 | 220 | 420 | 670 | 1000 | 500 | |||||||

Diameter(mm) | 500 | 700 | 1000 | 1200 | 1400 | 1600 | 1800 | |||||||

Power of Fan(Kw) | 3 | 7.5 | 11 | 18.5 | 22 | 30 | 45 | |||||||

Liquid Feed Power(Kw) | 0.37 | |||||||||||||

Pressure of Steam(MPa) | 0.4~0.6 | |||||||||||||

Consumption Steam(Kg/h) | 18 | 60 | 120 | 140 | 180 | 310 | 400 | |||||||

Compress Air Pressure( MPa) | 0.4~0.6 | |||||||||||||

Consumption of Air(m3/min) | 0.3 | 0.9 | 0.9 | 0.9 | 1.1 | 1.1 | 1.5 | |||||||

Working Temperature C | Room temperature~120C adjustable | Room temperature~120C adjustable | ||||||||||||

Noisy(dB) | Installed separated with fan | Installed separated with fan | ||||||||||||

FL Series Fluid Bed Dryer Machine

The machine is mainly used for the operations of mixing, granulating, drying and coating of granule "Top Spraying", etc of powder

material in pharmaceutical industry, foodstuff industry, chemical industry, etc. Such as granule of tablet, granule for quick

resolving drinking, condiment.

material in pharmaceutical industry, foodstuff industry, chemical industry, etc. Such as granule of tablet, granule for quick

resolving drinking, condiment.

Main Features

1) Mixing-granulator-dryer in one-step.

2) Adopting double chamber filtering bags system, removing dust completely.

3) Adopting multi-fluid nozzle, it gurantees that the formed granule is uniform and the content of powder is very low.

4) Can choose two bars explosion-proof design

5) Designed, manufactured and laid out by GMP

6)Design&Manufactured in accordance with JB20014-2004

1) Mixing-granulator-dryer in one-step.

2) Adopting double chamber filtering bags system, removing dust completely.

3) Adopting multi-fluid nozzle, it gurantees that the formed granule is uniform and the content of powder is very low.

4) Can choose two bars explosion-proof design

5) Designed, manufactured and laid out by GMP

6)Design&Manufactured in accordance with JB20014-2004

Workshop Environment

Customer Case

Packing & Delivery

Company Profile

Sino Pharmaceutical Equipment Development (Liaoyang) Co., Ltd. (SINOPED) is a professional manufacturer and supplier of pharmaceutical and chemical machinery and equipment in China. We belong to SINOPEC International Group.

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute.

We have a well-experienced team to manufacture pharmaceutical machinery and equipment and a professional design institute.

With rich experience in pharmaceutical machinery and equipment field and numbers of professional engineers, we have designed and developed many types of machinery and equipment in many varieties. Our main products are glass-lined reactors,fermentors,centrifuges, granulators, mixers, spray dryer, pulverizers, also have good relationship with famous factory for tabletpress,blister, packing machinery etc..

In the past years, we have made great achievements due to our good credit and service. We have established long-term

businessrelations with many customers and some of our overseas customers have appointed us to be their purchase agency in China.

Our products are exported to many countries & areas, such as Korea, India, Indonesia, Pakistan, Thailand, Vietnam, Japan,Denmark,Romania, Bulgaria, Russia, South Africa, Nigeria, the USA, Australia, Canada, Argentina and Chile. Besides machinery and equipment, we also supply production lines, turn key projects and know-how.

In SINOPED you can get your desired goods with the best prices and good quality. We welcome your enquiries from at home and abroad.

In the past years, we have made great achievements due to our good credit and service. We have established long-term

businessrelations with many customers and some of our overseas customers have appointed us to be their purchase agency in China.

Our products are exported to many countries & areas, such as Korea, India, Indonesia, Pakistan, Thailand, Vietnam, Japan,Denmark,Romania, Bulgaria, Russia, South Africa, Nigeria, the USA, Australia, Canada, Argentina and Chile. Besides machinery and equipment, we also supply production lines, turn key projects and know-how.

In SINOPED you can get your desired goods with the best prices and good quality. We welcome your enquiries from at home and abroad.

Exhibition

FAQ

1.SINOPED provide one-stop service(pre-sale,production,packing&after-sales) and we have independent R&D and design team to help customer solve pre-sale questions what they concern about.

2.At the same time,we will combine our own equipment to demonstrate to customers at sight.

During the equipment production process,we will continue to contact customers,and double confirm question.

3.When machine finish production,we will show customers for final confirmation.

For Package,we will adopt to standard woodencase,also will make waterproof treatment inside.

4.For after-sales,SINOPED provide free parts and parts delivery, when manufacture defects has been detected during normal operation (vulnerable parts not included) under warranty period.

And SINOPED will arrange engineer to answer customer question for install,debuging,etc all the time.

If necessarry,we will arrange video online to guide customer,also will arrange translator that customer can be better understand.

2.At the same time,we will combine our own equipment to demonstrate to customers at sight.

During the equipment production process,we will continue to contact customers,and double confirm question.

3.When machine finish production,we will show customers for final confirmation.

For Package,we will adopt to standard woodencase,also will make waterproof treatment inside.

4.For after-sales,SINOPED provide free parts and parts delivery, when manufacture defects has been detected during normal operation (vulnerable parts not included) under warranty period.

And SINOPED will arrange engineer to answer customer question for install,debuging,etc all the time.

If necessarry,we will arrange video online to guide customer,also will arrange translator that customer can be better understand.

Feedback

Похожие товары

Модель ZQG гладкая Беговая вибрационная сушилка для кровати

ZLG7.5 * 0,9 хорошее качество Вибрирующая Жидкостная кровать для солевой фабрики

Высококачественное фармацевтическое оборудование серии FG, флюидизированная кровать, сушилка

24 900,00 $

Машина для сушки чайного порошка

FG-15 малой емкости кипящим слоем сушилки или нанесение покрытия для лаборатории с использованием

Маленькая сушильная машина для семени кунжута

Сетчатая лента конвейера сушилка для еды для чая

38 765,00 $ - 38 770,00 $

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $