Прямая продажа с завода металл высокой чистоты

- Категория: >>>

- Поставщик: Advanced Targets Materials Co. Ltd.

Сохранить в закладки 1600202197986:

Описание и отзывы

Характеристики

Product Description

Cr (Chromiumr)

sputtering targets

CrAl (Chromium&Aluminum)

sputtering targets

Ti (Titanium))

sputtering targets

Cu(copper) Sputtering targets | TiAl(Titanium&Aluminum) Sputtering targets | C(graphite) Sputtering targets |

Cr, AlTi and AlCr sputtering targets and arcing cathodes are maindly used for deposition of hard coatings. The PVD process serves to increase the wear resistance of tools and compeonents over a wide range of temperature. Selected compositions are also used for decorative coating.

Advanced Targets Materials Co.,ltd has been accumulating nearly 20 years of experience in powder metallurgy, is supplying Cr/AlTi/AlCr targets with the advantages as below:

----High density

----Uniform and fine grained microstructure

----Homogeneous concerning distribution of chemical elements

----Low content of residual impurities

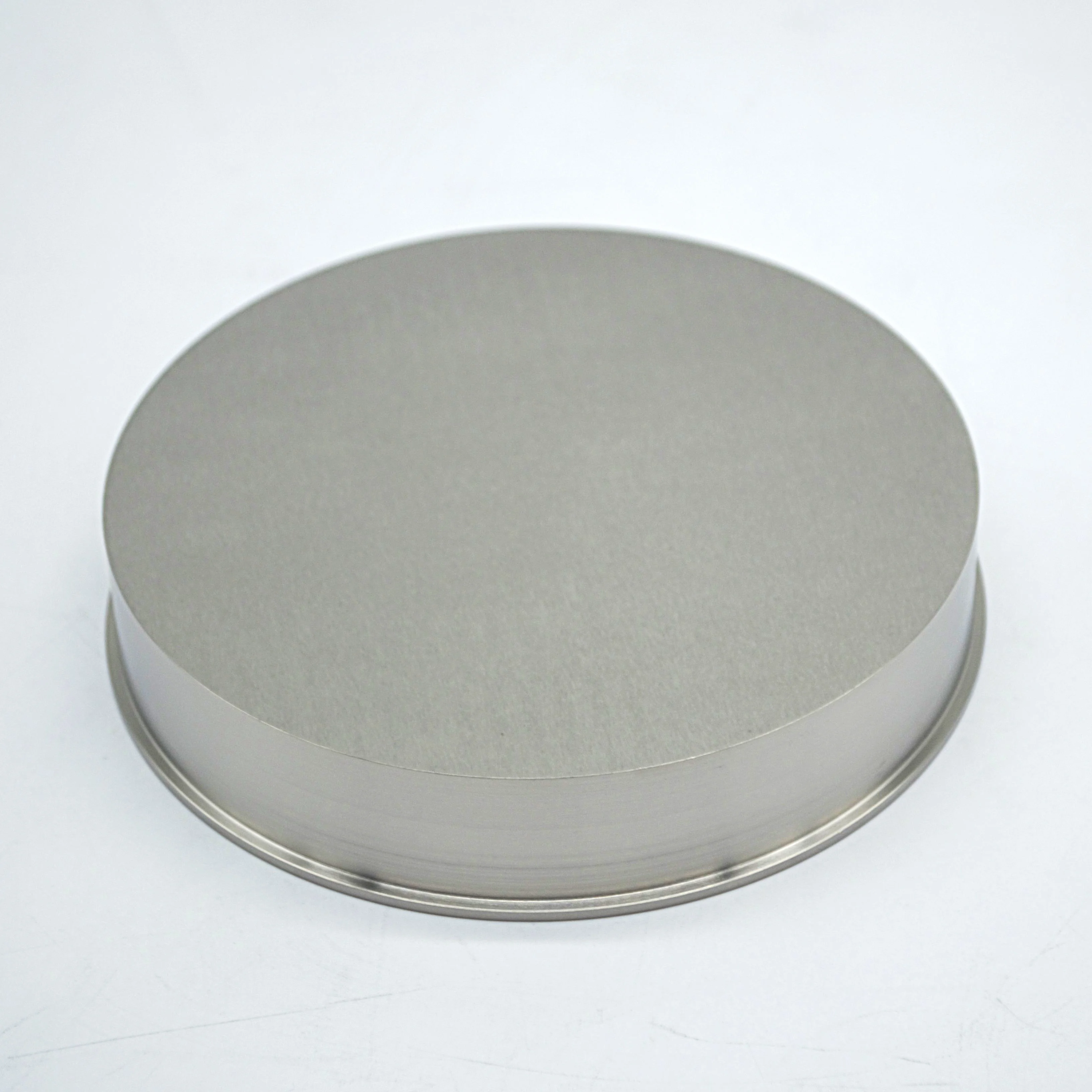

Detailed Images

Advanced Targets have been supplying lots of high-end hard coating products, meanwhile co-developed many tailor-made new products which are supporting customers leading in hard coating markets.

Cr sputtering targets

(1) In cutting tools coating, Such as cutting and drawing tools, various materials of pressing mold and mold, bearing, shaft, gauge, gear, etc

(2)Protection and decoration of automobile, bicycle, sewing machine, clock, instrument, daily hardware and other parts

(3)Storage of lubricating media, prevent non lubrication operation, improve the anti friction and wear resistance of workpiece surface. It is often used to coat the surface of sliding friction parts under heavy pressure, such as internal combustion engine

cylinder bore, piston ring, etc

(4)It has uniform luster, good decoration and good extinction:

(2)Protection and decoration of automobile, bicycle, sewing machine, clock, instrument, daily hardware and other parts

(3)Storage of lubricating media, prevent non lubrication operation, improve the anti friction and wear resistance of workpiece surface. It is often used to coat the surface of sliding friction parts under heavy pressure, such as internal combustion engine

cylinder bore, piston ring, etc

(4)It has uniform luster, good decoration and good extinction:

When graphite is used as target material,

graphite materials of different materials are selected according to different industries. Then the technical problems in the processing of graphite target should be considered. The requirements of target material are very strict, and the requirements of processing technology are also meticulous. The accuracy and error ofgraphite target are important factors.

Improve wear resistance, reduce friction coefficient and prevent adhesion.

It is a kind of coating on CNC tools. The single-layertitanium nitride coating is golden yellow, Vickers hardness is about 2300hv, and the maximum service temperature is 500 ℃.

It is akind of high cost-effective coating widely used in CNC tools.

It can also form composite coating with other elements such asaluminum and carbon, such as AlTiN

According to the special requirements of customers, we developed cral alloy target with ultra-fine grain structure, which can effectively reduce the production of liquid droplets in the coating process and provide the coating rate.

AlTi sputtering targets

It is widely used in the coating of milling cutter, drill bit, hobbing cutter and stamping die in mechanical processing. The excellent high temperature oxidation resistance can prolong the service life of tools and moulds; at the same time, it can also provide excellent decorative effect for skin of mobile phone shell.

Titanium aluminum target has the characteristics of high density, uniform structure, fine grain and stable product quality. It has been widely used in well-known coating centers at home and abroad, and the product quality has been widely recognized by customers.

Titanium aluminum target has the characteristics of high density, uniform structure, fine grain and stable product quality. It has been widely used in well-known coating centers at home and abroad, and the product quality has been widely recognized by customers.

If you have good ideas about target materials, macro target technology is willing to work with you to test and verify!

Product Presentation

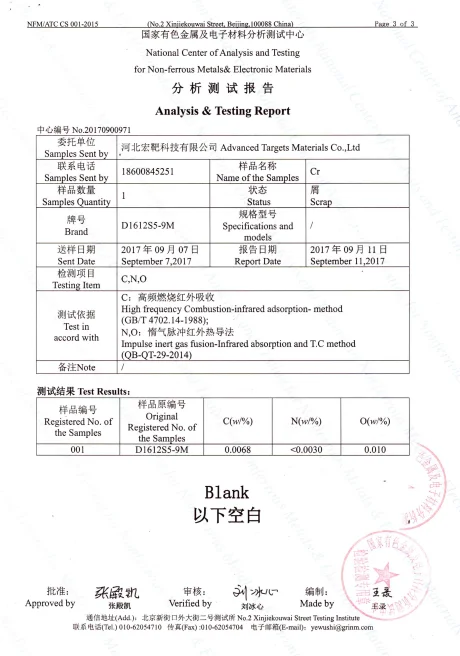

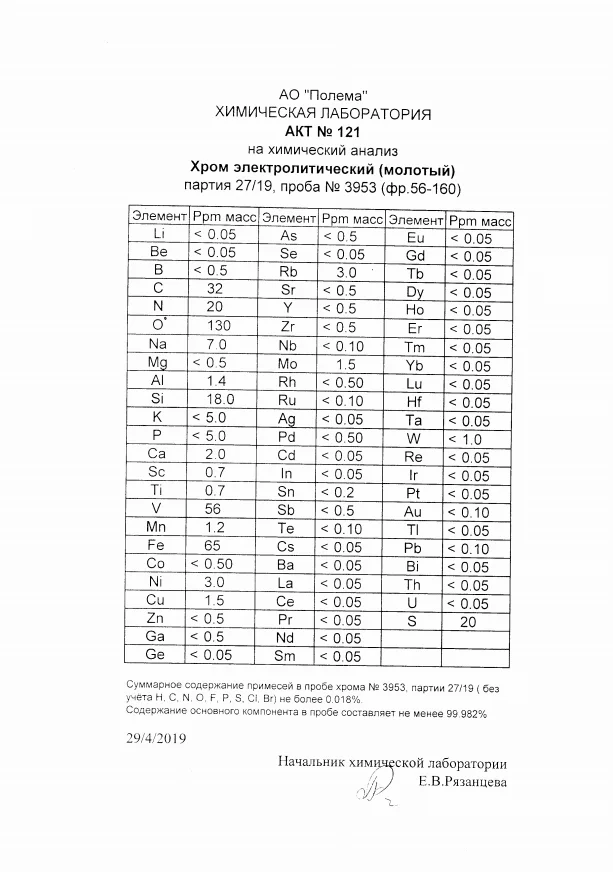

Certificate

Every pcs of sputtering targets from the powder materials item&number, mixing workers, outgas and HIP time,machining person and packing details are all made ourselves.

All of those step can promise you once a new sputtering target or method is created ,it could be copied and kept to support a stable quality products.

All of those step can promise you once a new sputtering target or method is created ,it could be copied and kept to support a stable quality products.

With ISO9001, COA, MSDS ,SGS test report certification.

Related Products

Company Introduction

Advanced Targets Materials Co., Ltd is one of the leading manufacturers of sputtering targets, arcing cathodes and evaporation materials for the PVD thin film companies worldwide. Advanced Targets has rich experience in manufacturing and R&D on sputtering targets and arcing cathodes. Driven by the spirit of innovation, Advanced Targets achieved lots of R&D progress, and some are worked together with Institute of Process Engineering Chinese Academy of Sciences, national center for Non-Ferrous Metals & Electronic Materials.

Advanced Targets’s products have been serving for the leading PVD service suppliers around the world. Consistent high quality and cost efficiency are the key advantages of Advanced Targets. Relying on material science and material processing know-how, Advanced Targets has won a good reputation worldwide.

Driven by the mission of “Innovation, Sincerity, Quality”, Advanced Targets has been supplying a wide range of

high-qualitysputtering targets and arcing cathodes recognized by many well-known companies in PVD thin film field.

Advanced Targets’s products have been serving for the leading PVD service suppliers around the world. Consistent high quality and cost efficiency are the key advantages of Advanced Targets. Relying on material science and material processing know-how, Advanced Targets has won a good reputation worldwide.

Driven by the mission of “Innovation, Sincerity, Quality”, Advanced Targets has been supplying a wide range of

high-qualitysputtering targets and arcing cathodes recognized by many well-known companies in PVD thin film field.

Packing&Shipping

Vacuum packing

Every pcs of the all targets will be in vacuum packing septartely first to avoid oxidation,contaminated,contact touch and so on.

Non fumigation wooden box packing outside

Vacuum packing sputter will be packed in cartons with fixed support

FAQ

1. Are you trading company or manufacturer ?

Advanced Targets: We are a professional manufacturer of PVD targets, powder metallurgical/Melting/plasma spray are the main process we focused on.

2.What is HIP process: HIP is a short name of Hot isostatic Pressing.

This technology is forming process combining simultaneous heating and pressing to consolidate powders in high temperature, high pressure as well as under argon(Ar) atmosphere, primarily used to eliminate voids and defects in materials. HIP is mainly applied to a wide range of Materials, it is the best fabrication

methods for Cr targets and powder metallurgy aluminum alloy targets.

methods for Cr targets and powder metallurgy aluminum alloy targets.

3. Do you have some experience if supplying hardcoating materials?

Advanced Targets: We have been keep supplying many kinds of

targets servicing for Eifeler/Balzers/ Hauzer/Platit/Kobelco/isys and other coating systems. They are satisfied by our goodservice and stable products quality.

targets servicing for Eifeler/Balzers/ Hauzer/Platit/Kobelco/isys and other coating systems. They are satisfied by our goodservice and stable products quality.

4: How long is your delivery time?

Advanced Targets: 15 days after order date for those regular size or samples, Normally 30 days for batch quantity.

5. Do you have quality control system:

Advanced Targets: Yes, we have been ISO 9001 qualified since 2015.And our quality control system have been mutual accepted by IQNET(International Certification Network).

6: Do you have Minimum order quantity requirement?

Advanced Targets: For common products, we donot have MOQ requirement. For R&D products, we can supply sample. 7: What is your payment method? Advanced Targets: T/T in advance, Paypal , Western Union and etc.

Похожие товары

Бильярдная перчатка сетка Нескользящая левая рука бильярдная снукерная перчатка для мужчин и женщин

1,40 $ - 1,80 $

Изготовленная на заказ полноцветная Изолированная коробка для замороженной рыбы, говядины, изолированные коробки для транспортировки пены для замороженных продуктов, коробка для охлаждения из пенополистирола

0,19 $ - 0,78 $

Запасные части SYNCPART JCB, силовой гусеничный стержень цилиндра 573/20001 573/20001 573/20001 для экскаватора-погрузчика JCB 3CX 4CX 5CX

Планшет 10,1 дюймов Восьмиядерный 4 Гб Ram 64 Гб Rom Android 12. 10,1 дюймовый планшетный ПК 2023

62,99 $ - 65,99 $

Лучшие продажи практические продукты компьютерных игр 128 ГБ 256 512 1 ТБ Накопитель Ssd внутренний жесткий диск для ноутбука

E329D воздухоохлаждающий шланг для экскаватора 230-2868 2302868

RT-S6-21B/ RT1221 дцт ВКЛ-ВЫКЛ Тип 15amp вкл/выкл тумблер

Новые поступления

Новинки товаров от производителей по оптовым ценам

Светлая Золотая морская солнечная энергия ландшафтное украшение постмодерн минималистский стиль чистая ручная роспись маслом 24x3 1 дюйм/60x80

35-53 $

Европейские антикварные простой Последние двойной металлической кровати

Автоматизированная складская система автоматического хранения в Гуанчжоу Eyda с эффективными стеллажами и

10 000-35 000 $

Декоративный чехол для PS5 Сменный Чехол консоли пластины Playstation5 пылезащитный с защитой от царапин

7,50-7,70 $

Лучшее качество детские подгузники для сухих подгузников новорожденных размер 2 4 и большие доставка или

3 $

Выключатель для формованного корпуса Schneider NSX100N 50KA AC 3P3D 25A TMD новая модель C10N3TM025

Буф2-.. М .. Краны

Оптовая продажа высококачественный сублимированный клубничный порошок Заводская поставка

5,50-6,40 $