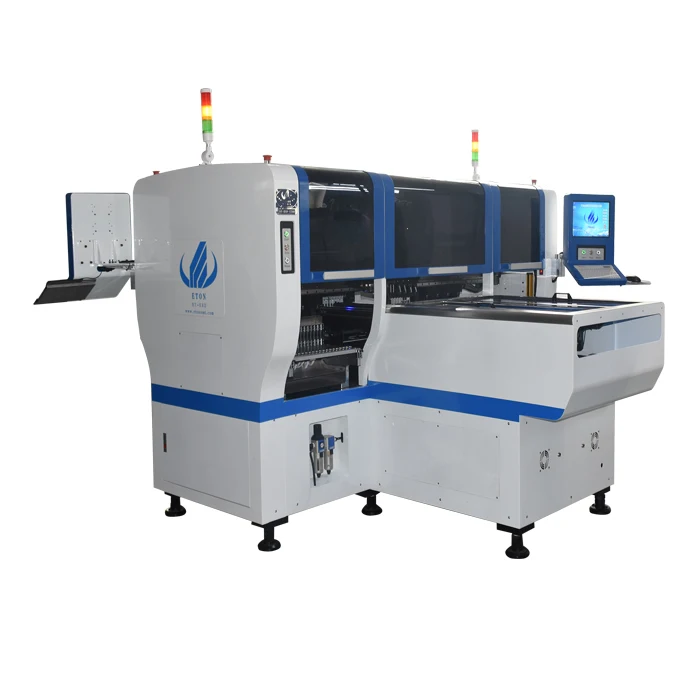

Двухмодульный Многофункциональный монтажный блок Питания SMD установка для размещения светодиодных ламп

- Категория: >>>

- Поставщик: Shenzhen Eton Automation Equipment Co. Limited

Сохранить в закладки 1600205040189:

Описание и отзывы

Характеристики

Dual module multifunctional mounter led bulb power driver SMD placement machine

1. The dual-system magnetic linear motor multifunctional high-speed placement machine can produce two different products at the same time.

2. The mounting head can take materials synchronously, which can improve the mounting efficiency of ordinary devices and ensure the precision of chip mounting. (Each placement head can rotate freely independently without affecting the placement speed)

3. High-speed synchronous recognition cameras: 4 sets of high-precision imported cameras, which can simultaneously perform visual correction on 24 sets of placement heads to absorb different components, improve placement efficiency and accuracy, and have a missing material replenishment function, which solves the precise placement of precision chips. Install small-size chips such as IC, QFN, etc. The smallest placement of 0402 chips. (Digital aerial photography camera, component recognition zero pause, avoid feeding error.)

4. Adopt X-axis magnetic linear motor + Y-axis low-noise precision screw structure, which greatly optimizes the service life and improves the placement accuracy; It has the characteristics of high precision, high stability and low wear.

5. The dual cantilever dual working area mode is more efficient, lower energy consumption, and fast; it has a wide range of adaptability and high compatibility.

| HT-E8D-600 |

L*W*H | 1950*2250*1650mm |

Total Weight | 2200kg |

PCB Length Width | MAX:600*350mm MIN:100*100mm |

PCB Thickness | 0.5~5mm |

PCB Clamping | Adjustable pressure pneumatic |

Mounting Mode | Group picking and separate placing, separate picking and separate placing |

Mounting height | <15mm |

No. of Camera | 4PCS |

Mounting Precision | ±0.04mm |

Mounting Speed | 90000CPH |

Components Space | 0.2mm |

Feeders Station | 48PCS single module |

No. of nozzles | 24PCS single module |

Power Consumption | 8KW |

Conveyor Transmission | MAX Length:600mm |

Electrical control | Independent research and development by ETON |

Motion control card module 1 set | Independent research and development by ETON |

X,Y,Z, Axis Drive way | High-end magnetic linear motor + servo motor |

1. Used in led lighting industry, power drive board, home appliance control board, etc.

2.Mounting components: LED chips, capacitors, resistors, lC, shaped components, etc.

3.Mounting products: It can perfectly mount various drivers, power supplies, circuit boards, lenses, linear bulbs, home appliance control panels, DOB, lamp tubes, street lights, down-lights, panel lights, corn lights, ceiling lights, wall lights, spotlights, etc.,

• Shenzhen ETON Automation Equipment Co., Ltd. was established in 2011. It is a national high-tech and dual-soft enterprise dedicated to the integration of R&D, production, sales and after-sales technical services of SMT high-speed placement machines. The company has always insisted on "creating a national brand, The goal of building an international Chinese enterprise is committed to providing customers with "professional, efficient and low-consumption" SMT automatic placement machines.

• While ETON has made great achievements in the field of LED patch, it has also been committed to technological innovation and development in the field of SMT patch. Since it began to develop multi-functional placement machines in 2014, after many years of concentrated research and development, it has finally achieved technology With breakthrough progress, we have successfully developed a variety of multi-functional general-purpose placement machines, which can perfectly mount various drivers, power supplies, circuit boards, lenses, linear bulbs and other products, and are suitable for various capacitors, resistors, ICs, Special shaped components, etc., have won wide recognition and good reputation in the market.

• Looking forward to the future, we believe that ETON will surely achieve better results in the field of SMT patch and make greater contributions to the industry and society!

♦ ETON mission: professional, excellent technology, sharing the results.

♦ ETON goal: to create value for customers, build international Chinese enterprises.

♦ ETON’s purpose: to create value for customers, creating benefits for society.

♦ ETON Vision: Determined to become the world’s most competitive manufacturer and service provider of pick and place machine and high-end electronic testing equipment.

Our company participates in many exhibitions every year. Domestic exhibitions include Guangzhou International Lighting Exhibition, Munich Shanghai Light Fair, Chongqing LED Exhibition and so on. Foreign exhibitions include Thailand exhibition, Turkey exhibition, India Mumbai exhibition, India Delhi exhibition, Pakistan exhibition, Egypt exhibition and so on.

We have exported machine to more than 20 countries, such as India, Egypt, Korea, Turkey, Brazil etc. Such as FSL,ETI,KONKA,OPPLE,MLS are our client, In India such as RK, Surya, skyquad are our client.

1. One-year warranty period. During the warranty period, any part of the machine can be repaired and replaced free of charge.

2. After purchasing our machine, our engineer will come to help you install the machine and provide free training, usually within 3~5 days to master the operation method of the machine.

3. Visit customers regularly to understand usage and collect customer opinions.

4. Regularly provide customers with the latest production technology and equipment information, and provide free software upgrade services for life.

5. Our company has an office in India, which can provide you with services faster.

6. Provide 24-hour online technical support.

7. A whole production line and other peripheral equipment can be configured for you.

8. If you have any other problems, we will do our best to help you solve them.

Похожие товары

Гидравлическое автоматическое оборудование для Выравнивания Земли, лазерный грейдер, оптовая продажа, устройство выравнивания земли

Автоматическая Гибкая кормушка для чаши, лента и катушка, высокоскоростная машина для склеивания катушки, проверка зрения

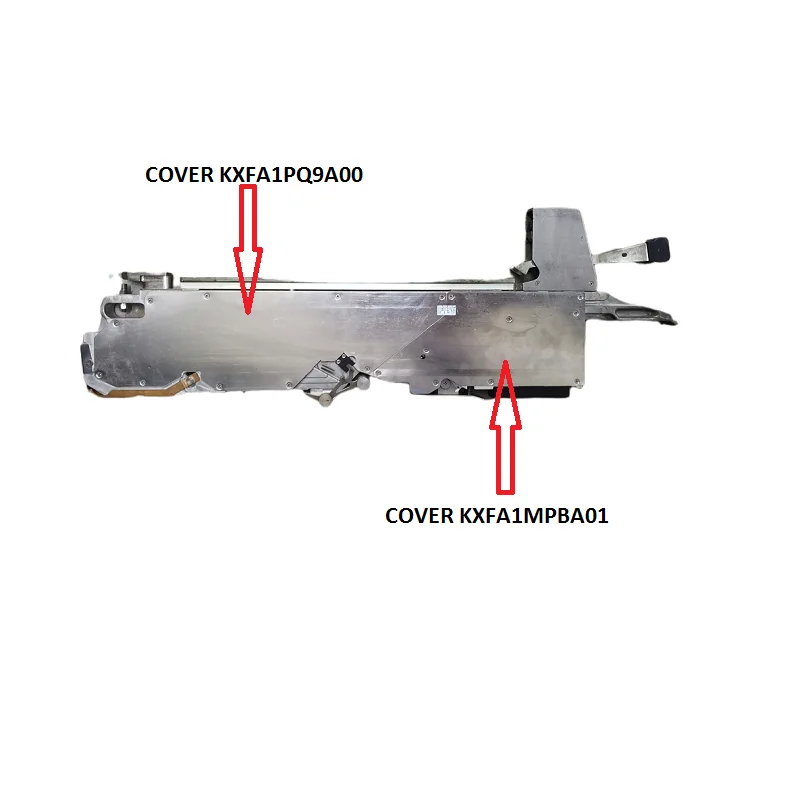

CM402 CM602 NPM Фидер Panasonic чип монтер 8 мм KXFW1KS5A00 12 мм KXFW1KS6A00 SMT SMD запасные части для машины для выбора и размещения

10 МГц-6000 МГц 6 ГГц широкополосный RF смещения подачи ВЧ блокиратор изолятор косой тройник для волна SDR LNA HAM радио антенна усилитель

Автоматическая Вибрирующая миска, запчасти, питатель для кристаллических компонентов SMD

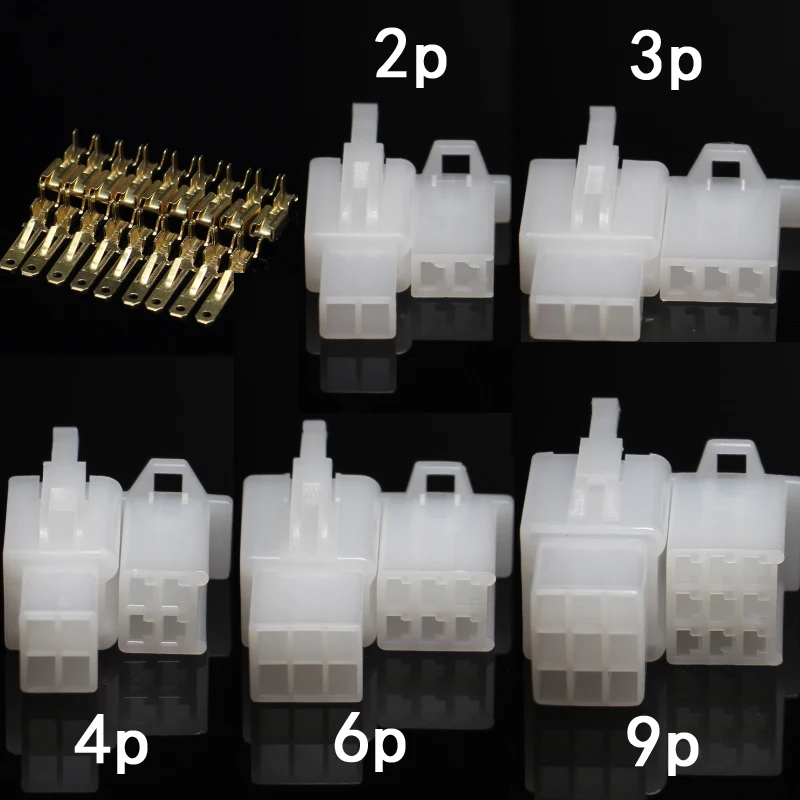

2,8 мм 2/3/4/6/9 контактный автомобильный 2,8 Электрический провод соединитель Мужской Женский кабель клеммные вилки наборы мотоцикл ebike автомобиль

2019 Bb крем Meso белый макияж Жидкая основа для макияжа отбеливающая Жидкая Основа/BB meso основа

Новые поступления

Новинки товаров от производителей по оптовым ценам