MBBR Biofilm Carrier Filter Media Making Machine экструзионная производственная линия

- Категория: Plastic Extruders >>>

- Поставщик: Zhangjiagang Huede Machinery Co. Ltd.

Сохранить в закладки 1600206008444:

Описание и отзывы

Характеристики

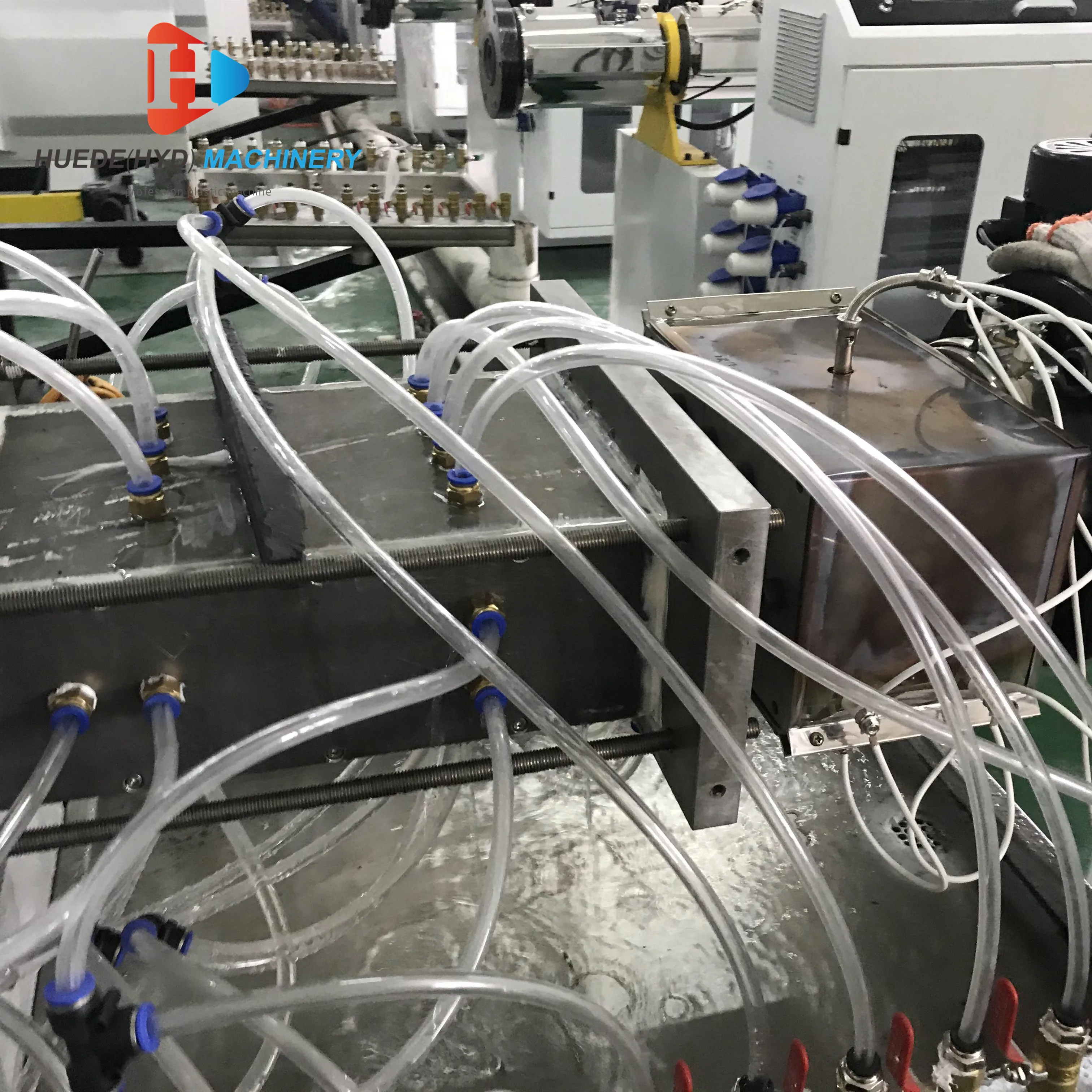

MBBR Biofilm carrier filter media making machine

1) Partial denitrification by external return sludge; A small part of the wastewater to be treated by biochemical treatment enters the pre anoxic tank through the one point inlet channel, while the external return activated sludge from the subsequent secondary sedimentation tank treatment unit enters the pre anoxic tank through the external return channel. The organic matter in the influent of the one point inlet channel and the carbon source degraded by internal respiration are used in the pre anoxic tank to denitrify the NO3 -- N brought by the reflux activated sludge;

2) In anaerobic phosphorus removal, most of the wastewater to be treated goes into the anaerobic tank through the two-point inlet channel. Without dissolved oxygen and NO3 -- N, the phosphorus accumulating bacteria in the anaerobic tank can absorb the easily degradable organic matter brought in by the two-point inlet channel by using the energy stored in the body and store it in the form of PHB; In the subsequent activated sludge aerobic tank and MBBR sludge membrane aerobic tank, the phosphorus accumulating bacteria can oxidize and metabolize the PHB stored in the body by molecular oxygen or combined oxygen, and generate energy, so as to absorb excessive phosphate from sewage, and the excessive phosphorus accumulating bacteria will be discharged into the biological pool along with the discharge of excess sludge to achieve the purpose of biological phosphorus removal

3) During anoxic denitrification, the effluent from the anaerobic tank enters the anoxic tank. At the same time, the internal return nitrification liquid from the internal reflux device of MBBR flows into the anoxic tank through the internal return channel of nitrification liquid. Denitrifying bacteria in the activated sludge can make full use of the easily degradable organic matter in the influent for denitrification and denitrification, so as to remove NO3 -- N in the internal return nitrification liquid, so as to achieve the purpose of deep denitrification. MBBR biological filler production line

MBBR biofilm carrier making machine electrical control:

1. Three phase four wire system

2. Voltage: 380V

3. Frequency: 50 Hz

Equipment summary:

1. Automatic drying and feeding machine

2. SJ-65 / 30 single screw extruder

3. Automatic hydraulic screen change

4. Mold (one out of two)

5. Sdt-6000mm vacuum setting table

6. Cooling water tank

7. Tractor cutting machine

NEW CUSTOMERS:

1.COUNTRIES WITH ENGINEERS

EGYPT | TUNISIA | VIET NAM | TURKEY | IRAQ | LIBYA | NIGERIA |

MALAYSIA | PAKISTAN | ALGERIA | INDIA | TANZANIA |

|

|

ONCE TIME 800 US DOLLAR, EXCLUDING FOOD, ACCOMMODATION AND TRANSPORTATION DATE WITHIN 10 DAYS

2. COUNTRIES WITHOUT ENGINEERS

(1) 100 US DOLLAR PER DAY

(2) FEE FOR VISA

(3) ROUND TRIP AIR FARE

(4) BOARD AND LODGING

REGULAR CUSTOMERS:

INSTALL WITH FREE REMOTE VIDEO G UIDANCE, IF NEED DOOR-TO-DOOR INSTALLATION AND COMMISSIONING SERVICE IS REQUIRED, 40% DISCOUNT ACCORDING TO NEW CUSTOMER CHARGE STANDARD

All equipment, including parts and components, shall be guaranteed for 24 months, and any problem within the warranty period shall be replaced free of charge (except screw and barrel)

Похожие товары

Экструзионная линия профиля окон и дверей из

Высокоскоростной пластиковый экструдер с одинарной двойной полостью, машины для изготовления угловых профилей из НПВХ, потолочный профиль для крыши

Мини машина для изготовления ПВХ труб ABS PLA пластиковый

Заводская цена ПВХ электрическая труба машина для производства пластиковых труб экструзионная линия с двойным винтовым

Лидер продаж автоматическая машина для баннеров с прямым впрыском

Бутылка с потреблением масла бутылка отжимом для устричного соуса томатного наполнитель

Двухшнековые экструдеры для гранул серии PP/PE/ABS CJWA Basic

Новые поступления

Новинки товаров от производителей по оптовым ценам