Распродажа с китайской фабрики гидравлический поворотный луч Кремниевая стальная линия резки по

- Категория: Линия поперечной резки >>>

- Поставщик: Jinan Suke Science & Technology Co. Ltd.

Сохранить в закладки 1600215251886:

Описание и отзывы

Характеристики

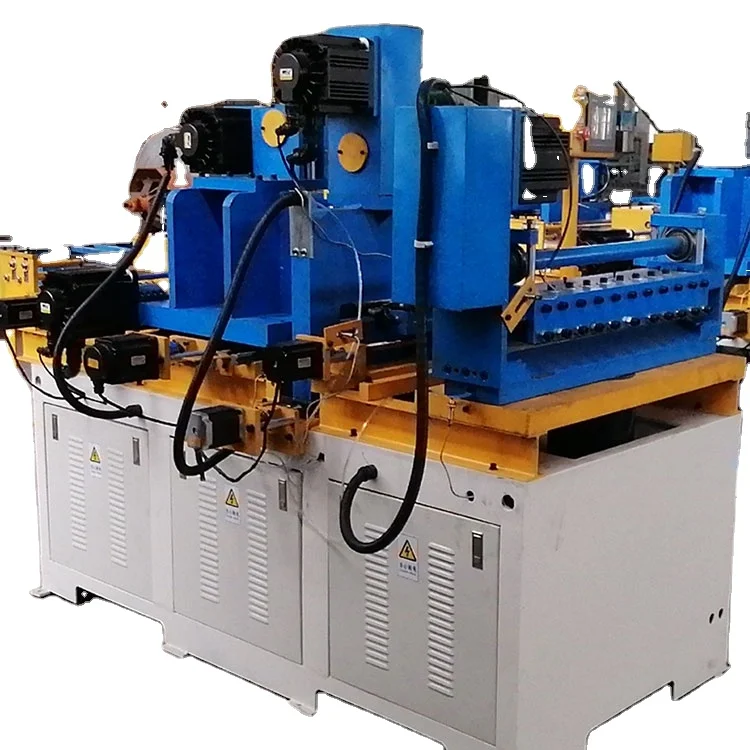

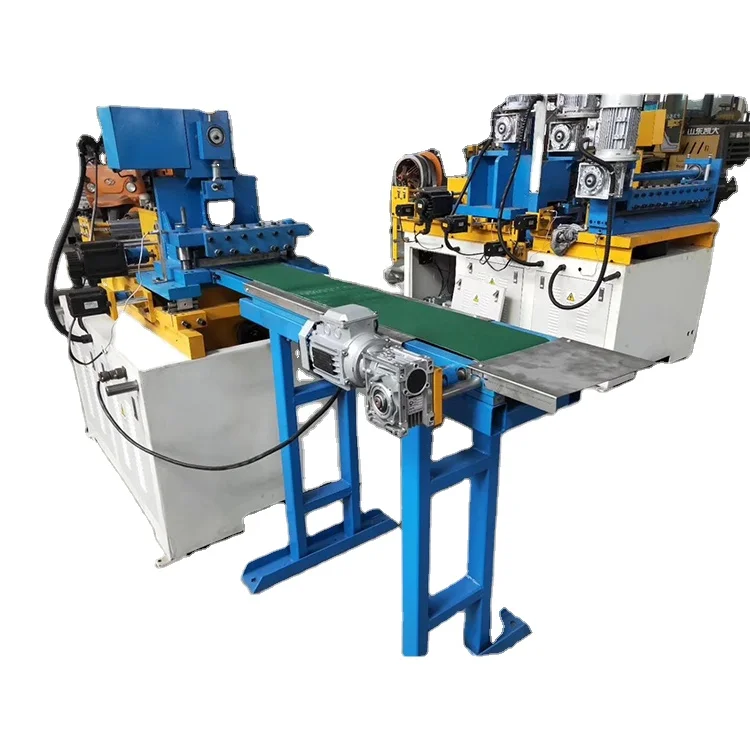

High speed NC Swing cutting machine/shear cut to length line for transformer core SK-4003VC

Uses and characteristics:

The equipment is mainly used for silicon steel break angle shearing and punching. It is a special numerical control equipment for producing transformer and reactor iron core. It can automatically the silicon steel sheet into the following drawing requirements

Rectangular bar type. Its characteristics:

1. cutting power: imported servo motor control technology, speed, noise, long lite.

2. feeding power: using large torque synchronous servo motor, with fast response, high positioning accuracy, low noise, small brake heat loss, long life

3. track positioning: the use of stepper motor drag ball screw, adjust the punching position, linear guide. Central positioning, positioning fast and accurate.

4. motion control: the use of advanced PLC controller, touch screen operation, simple and convenient.

5. material way: direct, tidy, fell to the receiving platform, or the use of conveyor belts to the receiving rack.

6. life guarantee: the equipment standard parts (linear guide rail, ball screw, all kinds of bearings) are imported famous parts, the basic parts

Technical Parameters:

No. | Item | Data |

1 | Type Code | 4003C |

2 | CRGO thickness | 0.23-0.6mm |

3 | CRGO coil width | 30-650mm |

4 | Cutting length | 1-999999mm |

5 | Cut-to-length tolerance | +/-0.1mm |

6 | Cutting angle tolerance | +/-0.03° |

7 | Hole position tolerance | +/-0.1mm |

8 | Notch position tolerance | +/-0.1mm |

9 | Burr height | Less than 0.02mm |

10 | Feeding speed | Max. 100m/min |

11 | Production speed | 30~60 pieces per minute |

12 | Punching/notching die | Carbide alloy |

13 | Cutting blade | Carbide alloy |

14 | Die & blade life | More than 1.2 million times before grinding |

15 | Max. step-lap stroke | 40mm |

16 | Step-lap quantities | 1, 2, 3, 4, 5, 6, 7, 8 |

17 | Servo motors | Delta from Taiwan |

18 | Dimension | About 6500 x 1800 x 1400mm |

19 | Weight | About 2000kg |

Control system

- Delta PLC

- Delta touch screen 7”

- Quantity, length, speed, angle combination can be pre-set on the touch screen

Welcome to visit us and choose our products!

Похожие товары

Стабильная производительность Nc гидравлический поворотный нож режущая линия по

Заводская розетка резка по длине стальная катушка поперечная Nc качающиеся

Машина для прямой резки кремниевой стали для сварочного трансформатора и реактора с прямоугольным сердечником

Гидравлическая машина режущая пластина Nc линия по

Автоматическая кремнистая сталь резки рама отрезного станка для определенную длину

Средне острый удобный продольно-резательный станок и машина для резки до

Высококачественная 1-6 мм Толстая CR HR стальная металлическая катушка режущая линия высокая точность резки до длины машина от

Новые поступления

Новинки товаров от производителей по оптовым ценам