ISO сертифицированный заводской индивидуальный изготовленный на станке с ЧПУ Регулируемый анодированный экструдированный алюминиевый направляющий ролик для рыболовного снаряжения

- Категория: >>>

- Поставщик: Dongguan Meijie Precision Technology Co. Ltd.

Сохранить в закладки 1600216000433:

Описание и отзывы

Характеристики

Our advantages | 1. Fast prototyping 2. 18 years' experience of CNC machining and stamping services 3. Small order acceptable 4. ISO9001/ISO14001/ISO-TS16949 certified factory 5. Quality assurance system 6. Quick production and delivery |

Our equipments | 1. CNC gantry milling machine, 2500x1300mm 2. CNC machining centers, drill and tap, engraving machine 3. CNC turning centers 4. Swiss lathes 5. Hydraulic stamping machines 6. Tapping machines 7. EDM wire cutting , drilling machine 8. Molded plastic injection machines 9. 3-dimensional measuring instruments, projectors, test machines |

Materials applicable | Aluminum, Copper, Stainless Steel, Titan Alloy, Hard Alloy, Teflon, Nylon, PEEK etc. |

Surface | Anodize, polishing, brushing, gold/silver/nickel plating, passivation, dacromet etc |

Tolerance | +- 0.005 to +-0.01mm |

Order quantity | Small order acceptable |

Quotation against | 2D drawings (PDF, JPG, DWG), 3D drawings (STP, IGS) or sample |

Lead time | 1.Prototyping 3-5 days for CNC machining parts, 2. Tooling -15-25 days 3. Production - depends on order quantity. |

ISO9001:2008

Passed the ISO9001:2008 quality system authentication and ROHS authentication.

ISO14001:2004

Environmental friendly and green development

ISO/TS16949:2009

We are capable to handle Auto parts cases.

Stamping workshop

CNC milling workshop

CNC machining centers, high speed drill and tap center

CNC turning workshop

Slant bed CNC turning machine, diameter range from 200 to 630mm

Laser cutting and welding workshop

Robot arm laser welding

The following are some products we made for our customers.

Electronics chassis

Acoustic enclosure

Plastic acoustic enclosure for LG Audio

Medical instrument components

Power supply chassis

Aluminum face massager for Thomas MediCare

SPCC chassis

Under-water camera enclosure

We offer our customers with quality products and trustworthy service, the following are our long term based customers to the name but a few.

CNC Machining Service

We offer CNC milling and turning service, 3 axis to 5 axis machining capabilities, both standard and live-tooling CNC turning and milling.

Till today, we own 23 CNC mills, among those are, 18 sets of 3 axis, largest one 2000mm x 1300mm gantry type, 3 sets of 4 axis and 2 sets of 5 axis. 20 CNC lathes, max turning diameter applicable range from 150mm to 630mm.

Sheet Metal Fabrication

Single & progressive stamping with punching dies, laser cutting and CNC bending for larger sizes, we are skilled and experienced for electronics enclosures, wall & chasis, shim, gasket and spring clips.

Molded Injection Plastics

More than 70 molding injection machines in 3 workshops, mode-locked pressure ranges from 60T to 750T, 20 years OEM experiences for LG, Sony, Panasonic, Philips, Saic Toyota and GM Brasil, products include Audio devices, gears for DVD, recorder, camera, housing and cup holder.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: It is about 15-20 days, it is according to order quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below.

Похожие товары

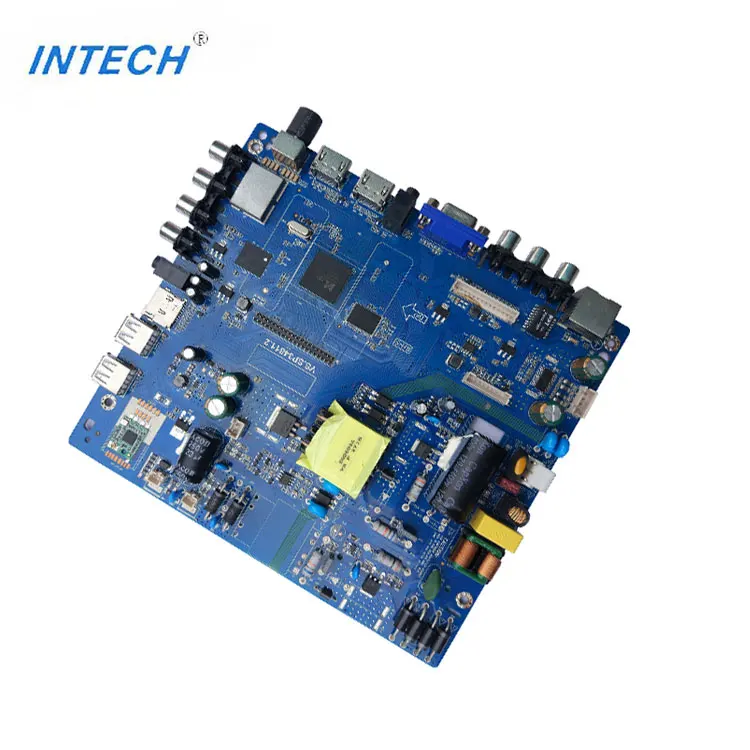

94V0 PCB design pcba smt cctv dvr pcb board assembly service

High Precision Oem Guide Rail Linear Bearing Aluminum Shaft Support

New Version Sport 0 Smartwatch T500 Plus Y68 U8 U9 1.7 inch Full Touch Screen Fitness Tracker Blood Pressure Smart Watch

Высококачественные направляющие валы OEM ISO9001 Heavy Duty Professional Factory

Умные часы V9 4G, 3 гб + 32 гб, Android 7,1, четырехъядерный процессор MTK6739, смарт-часы с двойной камерой, 1,6 дюйма, пульсометр, GPS-часы

Ролик из нержавеющей стали, неподвижная дорожка, ролик из нержавеющей стали, направляющая для подъема шкива, Оптовая поставка

CNC обработки фрезерные стали нержавеющей направляющей шпильки кусты для промышленного

Новые поступления

Новинки товаров от производителей по оптовым ценам