Высококачественный промышленный PP F46 мини воздушный масляный водяной Pvdf Ptfe Пластиковые химические двойные насосы пневматический мембранный насос

- Категория: >>>

- Поставщик: Nanjing Chutuo Shipbuiiding Equipment Co. Ltd.

Сохранить в закладки 1600216141029:

Описание и отзывы

Характеристики

Product Description

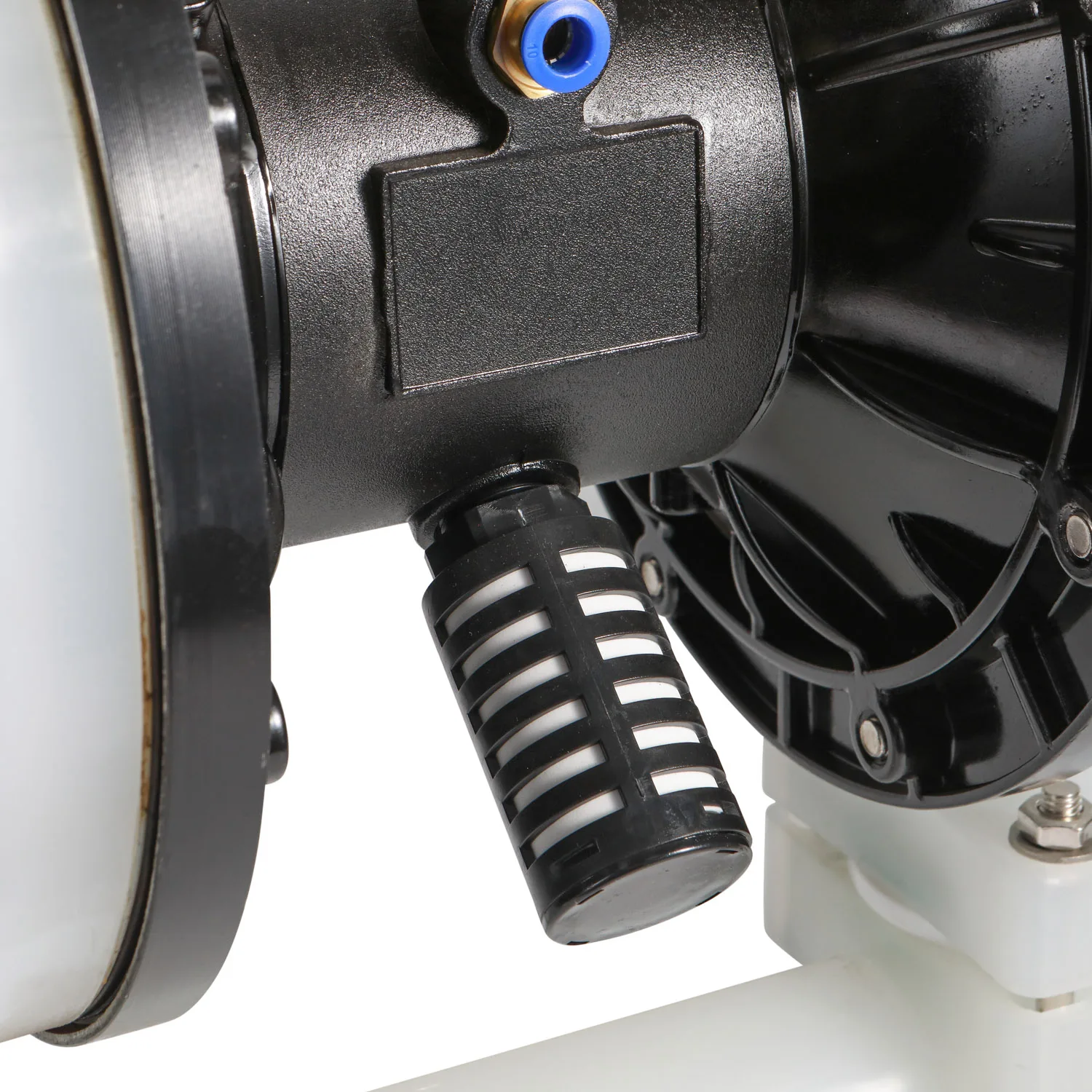

Air Operated Plastic Diaphragm Pump:

An air operated diaphragm pump designed for simplicity in operation and maintenance. Safe for use in explosive environments. The Metal pump lines provides the durability, chemical resistance, abrasion resistance, and temperature range required for a variety of process and waste applications. The standard material combination is composed of aluminum casing and neoprene diaphragm, balls and valve seat for general purpose non aggressive applications such as in oil and petroleum based fluids. Cast iron, 316 stainless steel and hastelloy casing materials are available as well.

QBK is coosai's new developed series of AODD pump which is also the third generation, it has the virtue of long service life and nonstop operation, not only it can convey some uneasy flowed medium, with the merits the merits of self-pumping pump, diving pump, shield pump, slurry pump and impurity pump etc.

Note: When the air operated diaphragm pump works, install the air filter to leach the moisture form the compressed air, and install the manometer at the outlet of pump, so to avoid damaging as too high pressure, when the pump doesn’t need work, please clean it in time to prevent from concreting

QBK is coosai's new developed series of AODD pump which is also the third generation, it has the virtue of long service life and nonstop operation, not only it can convey some uneasy flowed medium, with the merits the merits of self-pumping pump, diving pump, shield pump, slurry pump and impurity pump etc.

Note: When the air operated diaphragm pump works, install the air filter to leach the moisture form the compressed air, and install the manometer at the outlet of pump, so to avoid damaging as too high pressure, when the pump doesn’t need work, please clean it in time to prevent from concreting

Air Operated Plastic Diaphragm Pump Feature:

1.It’s unnecessary to pour the drawing water, the suction lift reaches 5m height, the delivery lift reaches 50m length.

2.Wide flow and good performance. The diameter allowed to pass the max grain reaches 10mm. The damage is very less to the pump while exhausting the slurry and impurity.

3.The delivery lift and flow can pass the pneumatic valve open to realize the step less adjustment ( the pneumat- ic pressure adjust ment is between 1-7bar).

4. This Diaphragm pump has no rotary parts and no bearing seals.The diaphragm will completely separate the exhausted medium and pump running parts,working medium. The conveyed medium can’t be leaked outside. Thus it will not cause the environmental pollution and human body safety dangerous while exhausting the toxin and flam- mable or corrosive medium.

5.No electricity. It’s safe and reliable while using in the flammable and explore places.

2.Wide flow and good performance. The diameter allowed to pass the max grain reaches 10mm. The damage is very less to the pump while exhausting the slurry and impurity.

3.The delivery lift and flow can pass the pneumatic valve open to realize the step less adjustment ( the pneumat- ic pressure adjust ment is between 1-7bar).

4. This Diaphragm pump has no rotary parts and no bearing seals.The diaphragm will completely separate the exhausted medium and pump running parts,working medium. The conveyed medium can’t be leaked outside. Thus it will not cause the environmental pollution and human body safety dangerous while exhausting the toxin and flam- mable or corrosive medium.

5.No electricity. It’s safe and reliable while using in the flammable and explore places.

6.It can be soaked in medium.

7.It's convenient to use and reliable to work. Only open or close the gas valve body while starting or stopping. Even if no medium operation or pausing suddenly for long time because of accident matters, the pump will not be damaged caused by this. Once over loading, the pump will automatically stop and possesses the self protection function. When the load recovers normally, it also can start automatically.

8.Simple structure and less wearing parts. This pump is simple in structure, installation and maintenance. The medium conveyed by the pump will not touch the matched pneumatic valve and coupling lever etc. Not like other kinds pumps, the performance will drop down gradually because of the damages of rotor, gear and vane etc.

9.It can transmit the adhesive liquid(the viscosity is below 10000 centipoises).

10.This pump needn't the oil lubricant. Even if idling, it has any influence to the pump. This is a characteristic of this pump.

7.It's convenient to use and reliable to work. Only open or close the gas valve body while starting or stopping. Even if no medium operation or pausing suddenly for long time because of accident matters, the pump will not be damaged caused by this. Once over loading, the pump will automatically stop and possesses the self protection function. When the load recovers normally, it also can start automatically.

8.Simple structure and less wearing parts. This pump is simple in structure, installation and maintenance. The medium conveyed by the pump will not touch the matched pneumatic valve and coupling lever etc. Not like other kinds pumps, the performance will drop down gradually because of the damages of rotor, gear and vane etc.

9.It can transmit the adhesive liquid(the viscosity is below 10000 centipoises).

10.This pump needn't the oil lubricant. Even if idling, it has any influence to the pump. This is a characteristic of this pump.

Pneumatic Diaphragm Pump Main Usage:

√ Marine time: sewage, sea water, diesel oil drainage and transportation;

√ Electricity: waste water, strong acid and strong alkaline drainage and transportation;

√ Automobile: sealant, adhesive, plating liquor, solvent, paint supply and transportation;

√ Chemical industry production: cleaning agent, binder, printing ink, cleaning/polishing, paint/dye;

√ Mine: sewage, turbid water and thin slurry drainage

.

√ Electricity: waste water, strong acid and strong alkaline drainage and transportation;

√ Automobile: sealant, adhesive, plating liquor, solvent, paint supply and transportation;

√ Chemical industry production: cleaning agent, binder, printing ink, cleaning/polishing, paint/dye;

√ Mine: sewage, turbid water and thin slurry drainage

.

Air Operated Plastic Diaphragm Pump Applications:

The diaphragm pumps are driven with compressed air without the need of electric power. Widely used for leak proof applications in industries like petrochemical chemical metallurgy and ceramics etc. Applicable to liquids of leaky corrosive inflammable and explosive & hazardous properties

Air-Operated Diaphragm Pump

Air Operated Plastic Diaphragm Pump

QBK-25 QBK-40 QBK-50

Pneumatic PP Diaphragm Pump

QBK-25 QBK-40 QBK-50

Details Images

NO. | DESCRIPTION | UNIT |

1 | Pneumatic Diaphragm Pump Plastic 1' SEMPO Brand | SET |

2 | Pneumatic Diaphragm Pump Plastic 1.5' SEMPO Brand | SET |

3 | Pneumatic Diaphragm Pump Plastic 2' SEMPO Brand | SET |

4 | Pneumatic Diaphragm Pump Plastic 3' SEMPO Brand | SET |

5 | Pneumatic Diaphragm Pump Plastic 0.5' SEMPO Brand | SET |

6 | Pneumatic Diaphragm Pump Plastic 4' SEMPO Brand | SET |

Recommend Products

Company Profile

Packing & Delivery

Exhibition

FAQ

Q1:What is your company advantage

A1:We are more than 15 years golden men of Alibaba, And We have Warehouse Capacity. Authorization of "AAA Grade Credit Enterprise" from Government.

Q2:How long is the delivery time?

A2:1-15days quick delivery time. Abundant stock items at hand big stock capacity guarantee

(10000㎡-Warehouse)Various Logistics Option(DHL, TNT,Rail, Air, Sea Freight)

Q3:Price Reasonable or Competitive?

A3:We have been in this trade more than 15 years which control the production from material have warehouse capacity. So we always can guarantee quality with better price.

Q4:Can you make samples as provided design?

A4:Of course !! We can customize the sample according to the customer’s need or even only by specifications, and don’t worry about the tests, we can pass it !.

Q5:Do you have QC system?

A5:Yes, we do, we have 5 times strictly and inner inspection before packing .

Q6:How about your after sale services?

A6:We do accept to change the goods within 30days after delivery if it’s our side caused quality problems.

Q7:When is your convenient time for buyer to contact?

A7:We have online replying services for 24 hours, so we will respond any time at client’s convenience.

Q8:Accepted OEM order?

A8:Yes, we have full experience of OEM & ODM orders.

A1:We are more than 15 years golden men of Alibaba, And We have Warehouse Capacity. Authorization of "AAA Grade Credit Enterprise" from Government.

Q2:How long is the delivery time?

A2:1-15days quick delivery time. Abundant stock items at hand big stock capacity guarantee

(10000㎡-Warehouse)Various Logistics Option(DHL, TNT,Rail, Air, Sea Freight)

Q3:Price Reasonable or Competitive?

A3:We have been in this trade more than 15 years which control the production from material have warehouse capacity. So we always can guarantee quality with better price.

Q4:Can you make samples as provided design?

A4:Of course !! We can customize the sample according to the customer’s need or even only by specifications, and don’t worry about the tests, we can pass it !.

Q5:Do you have QC system?

A5:Yes, we do, we have 5 times strictly and inner inspection before packing .

Q6:How about your after sale services?

A6:We do accept to change the goods within 30days after delivery if it’s our side caused quality problems.

Q7:When is your convenient time for buyer to contact?

A7:We have online replying services for 24 hours, so we will respond any time at client’s convenience.

Q8:Accepted OEM order?

A8:Yes, we have full experience of OEM & ODM orders.

Похожие товары

Насос охлаждающей жидкости CNC Machine

Насос Электрический шаговый 24 В

Бесщеточный моторный насос постоянного тока водяной для сельского хозяйства погружной мини-водяной

249,59 ₽ - 332,79 ₽

Электрический и пневматический железный чугунный горизонтальный двигатель высокого давления полуоткрытый крыльчатый насос для нефтяных химикатов

38 824,63 ₽ - 88 742,00 ₽

CISO GT PLUS автоматические системы смазки 220 В Электрический масляный насос

Бесмасляный вакуумный насос OL180A небольшой тихий для дезинфекции простыней поршневой сухой высокого отрицательного давления

4 886,98 ₽ - 5 943,62 ₽

Погружной насос для дренажа

18 524,90 ₽ - 23 294,78 ₽

Новые поступления

Новинки товаров от производителей по оптовым ценам

Прямая Продажа с фабрики 65 см Модернизированный подвесный стерео голографический проектор светодиодный вентилятор высокой четкости экран 3D дисплей

155-185 $

Оригинальная популярная клавиатура для рабочего места Genos2 с 76 клавишами

200 $

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $