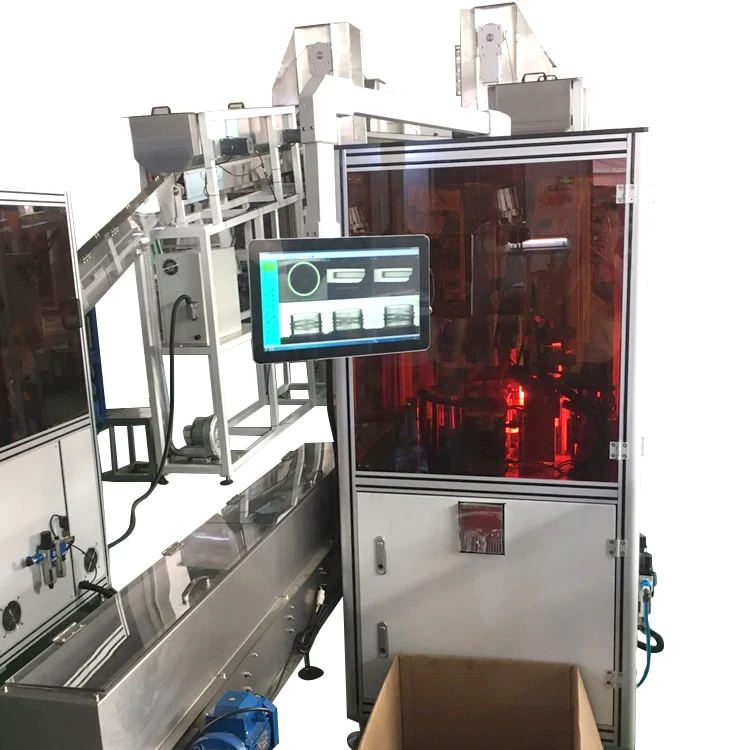

Система визуального контроля качества CCD для проверки и внешнего вида продукта

- Категория: Other Plastic & Rubber Machinery >>>

- Поставщик: Guangzhou Rijing Automation Machinery Co. Ltd.

Сохранить в закладки 1600217047013:

Описание и отзывы

Характеристики

CCD visual inspection system

Technical parameters

| Test accuracy | 0.005-0.015mm |

| Test cycle | 0.1-0.25s |

| Power&voltage | 1.5KW; 220V 50Hz /fit customer area |

| Testing speed | 14000 pcs/h to 36000 pcs/h |

| Dimension L*W*H (mm) | 2700*2000*2500 |

Reliable product quality, standard accessories

Application

1. Bottle caps QC:

Quality control, visual system (CCD/QC) for bottle caps applied in the demanding packing of edible oil, mineral water, beverage, milk, wine, etc.

Visual system to check bottle caps if a black spot, oil, and any contamination, defective products, faulty printing, etc.

2. Extensive application:

QC for printing products, electrical parts, plastic products, hardware parts, etc.

Visual system to check and classify defective printing products, or defective electrical parts or defective plastic products or hardware parts, etc.

3. Customer-oriented design and application.

Features

1. High accuracy testing

Our visual testing machine is installed with 6 camera lens and testing from all the perspectives of 360°

2. Meet national package machinery standards

It complies with food safety standards, the machine's main material is SS304.

It complies with national electrical & low noise standards.

3. Extra function

It also has more functions such as height measurement, counting, sterilization, the anti-static, fixed-quantity setting for encasement, and so on.

4. Self-research and customer-oriented design

We ourselves have a creative and professional technical&research team.

We make every machine to meet customer special needs.

Outside packing: standard export wooden cases

Inner packing: stretch film, adhesive tape, desiccant

License & Certification

RIJING& Customers in Chinaplas

Life-long technology support and good after service.

Our aim

Create value for customers, become the client's business partner!

Похожие товары

Low Temperature Atmospheric Cleaning Corona Plasma Surface Treatment Machine Small Head Purge Chemicals Equipment

PS foam panel production line

Аппарат для очистки низкотемпературной поверхности плазменного процессора с прямым впрыском

Горячая Распродажа, машина для обработки коронавируса из нетканого материала

Портативная плазменная машина для очистки поверхности для обработки стекла для смартфона

Автоматическая подача CCD визуальная оптическая Сортировка контроль качества визуальная Инспекционная машина

Блистерные пленочные рулоны для автоматических упаковочных машин

Новые поступления

Новинки товаров от производителей по оптовым ценам