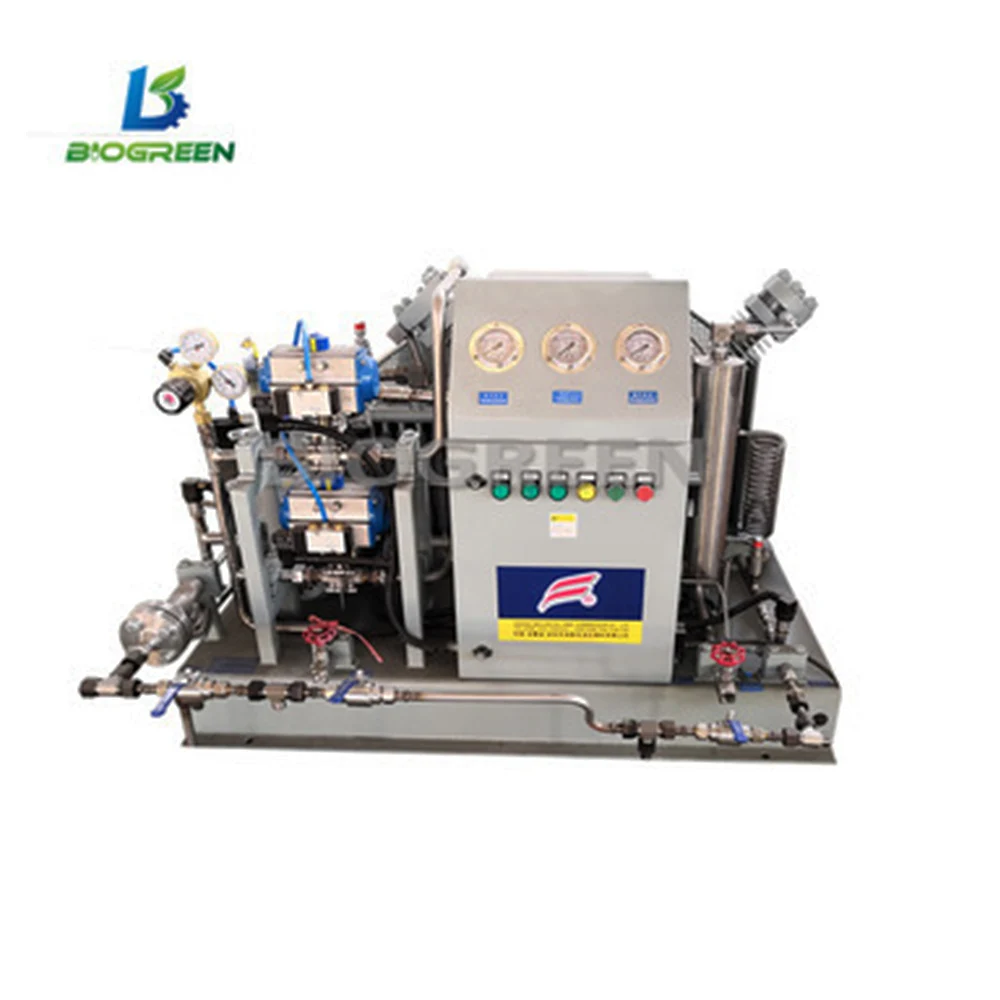

Автоматическая Сверхкритическая машина для экстракции CO2 CBD Oil

- Категория: >>>

- Поставщик: Wuxi Biogreen Pharma Technology Co. Ltd.

Сохранить в закладки 1600222300907:

Описание и отзывы

Характеристики

What is CO2 Extraction?

The CE Automatic Supercritical CO2 Extraction Hemp for CBD Oil Products process creates phase changes in carbon dioxide utilizing temperature and pressure. CO2 is known as a "tunable solvent" making it extremely versatile for creating a multitude of end products by controlling temperature and pressure. These phase changes create an environment to drop out differing weights of components in the plant material.

The CE Automatic Supercritical CO2 Extraction Hemp for CBD Oil Machine design of the Biogreen Series systems allow for separation and collection of these constituents during a single extraction. This enables collection of light essential oils separately from other desirable constituents and heavier lipids. Supercritical CO2 fluid extraction (SCFE) methodology delivers a clean, unaltered, consistent-yet-flexible product.

Why use CO2?

The primary reason is to create a pure, clean, quality oil that is safe to produce with little-to- no post-processing, unlike toxic solvents that may require many hours to purge the solvent trapped in the oil. In addition, multiple industries have proven that the highest efficiencies in commercial processing utilize CO2.

CO2 is efficient, inexpensive and is a "tunable" solvent. The ability to "tune" the extraction process can not be overstated - especially with a system that will separate constituents during an extraction. You can target specific compounds, like terpenes (terpenoids) through different parameters. CO2 is also a sanitizing agent, prolonging shelf life and with the proper system and environment, yields food and medical grade oils.

20L PLC Automatic Supercritical CO2 Essential Oil Extracting Machine is the cleanest, safest method for extracting plants such as hops, hemp and a wide range of nutraceuticals and organic crops.

Supercritical co2 extraction machine parameters | ||

Volume of Extraction kettle | Customized from 1-1500L | |

Pressure of extract | 400-750bar | |

Temperature of extract | Room Temp - 85 degrees | |

Extraction kettle and Separate kettle quantity | 1-6 pcs according to customized | |

Co2 pump flow | 50L-1200L according to Capacity | |

Control way | PLC or Valve | |

Machine power | 10KW-120KW | |

Dimension | According to size of machine | |

Production time | 40 days | |

During CO2 extraction, a series of pressurized chambers and pumps are used to expose CO2 to high pressure and very low temperatures, resulting in an extracted oil containing high amounts of CBD.

At the start of extraction, one chamber will hold pressurized CO2, while a second pressurized chamber holds the hemp plant. The CO2 is then pumped from the first chamber into the second. The presence of supercritical CO2 breaks down the hemp also in the chamber, causing the oil to separate from the plant material. Finally, the CO2 and oil are pumped together into a third chamber. The gas evaporates, leaving an extract of pure CBD oil behind.

While it requires expensive specialized machinery, CO2 extraction is the preferred method for making CBD products. It’s extremely safe and efficient at producing high concentrations of CBD in the resulting oil—as much as 92% according to one analysis.

What Is the Best Extraction Method for CBD Oil? | ||||

Pros | Cons | |||

CO2 Extraction | Efficient Highest concentration of CBD Easier to adjust concentration No toxic residue No chlorophyll | Expensive | ||

Steam Distillation | Inexpensive No toxic residue No chlorophyll | Inefficient Inconsistent concentration of CBD Potential for heat to damage CBD oil | ||

Hydrocarbon Solvent Extraction | Efficient Inexpensive Consistent concentration of CBD No chlorophyll | Potential for toxic solvent residue | ||

Natural Solvent Extraction | Efficient Inexpensive No toxic residue | Presence of chlorophyll affects taste Lower concentration of CBD | ||

Похожие товары

Высокоэффективный простой в использовании дистиллятор эфирного масла, экстрактор эфирного масла, экстрактор эфирного масла 10 л

Двухмоторный двухрычажный сварочный очиститель дыма, пылесборник, лазерный резак, экстрактор дыма

Складная бутылка для вина, спирта, напитков, 330 мл, 6 упаковок

Портативный сварочный вытяжной Передвижной сварочный экстрактор или паяльный вытяжной экстрактор

Машина для извлечения алкоголя, машина для извлечения масла cbd co2

Безопасный и эффективный водорастворимый консервант натрия этилпарабена CAS

Настольная лабораторная Сверхкритическая машина для экстракции co2 конопли/экстрактор масла co2

Новые поступления

Новинки товаров от производителей по оптовым ценам