Рельефный дизайн петли катушки ворса ПВХ катушки двери входного соединения коврик

0,60 $ - 1,80 $

Сохранить в закладки 1600226789080:

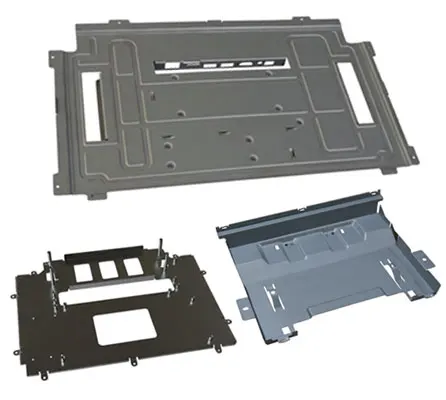

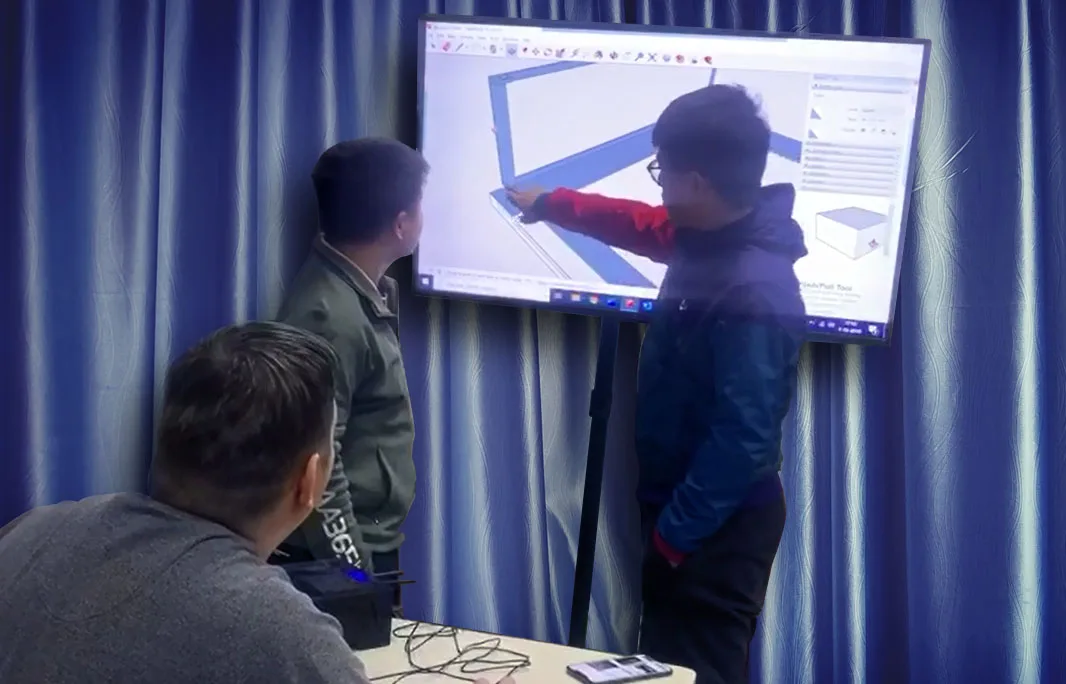

Process support | Laser cutting 、punching 、bending 、stamping 、reveting 、Welding 、polish 、surface treatment 、CNC machining 、CNC milling 、CNC turning、Prototype ,plastic inection molding 、Assembly | ||||||

Material | Aluminum 、Steel 、Copper 、Brass 、Plastic | ||||||

Certificate | SGS 、COC 、Do different tests according to customer's request | ||||||

Новинки товаров от производителей по оптовым ценам