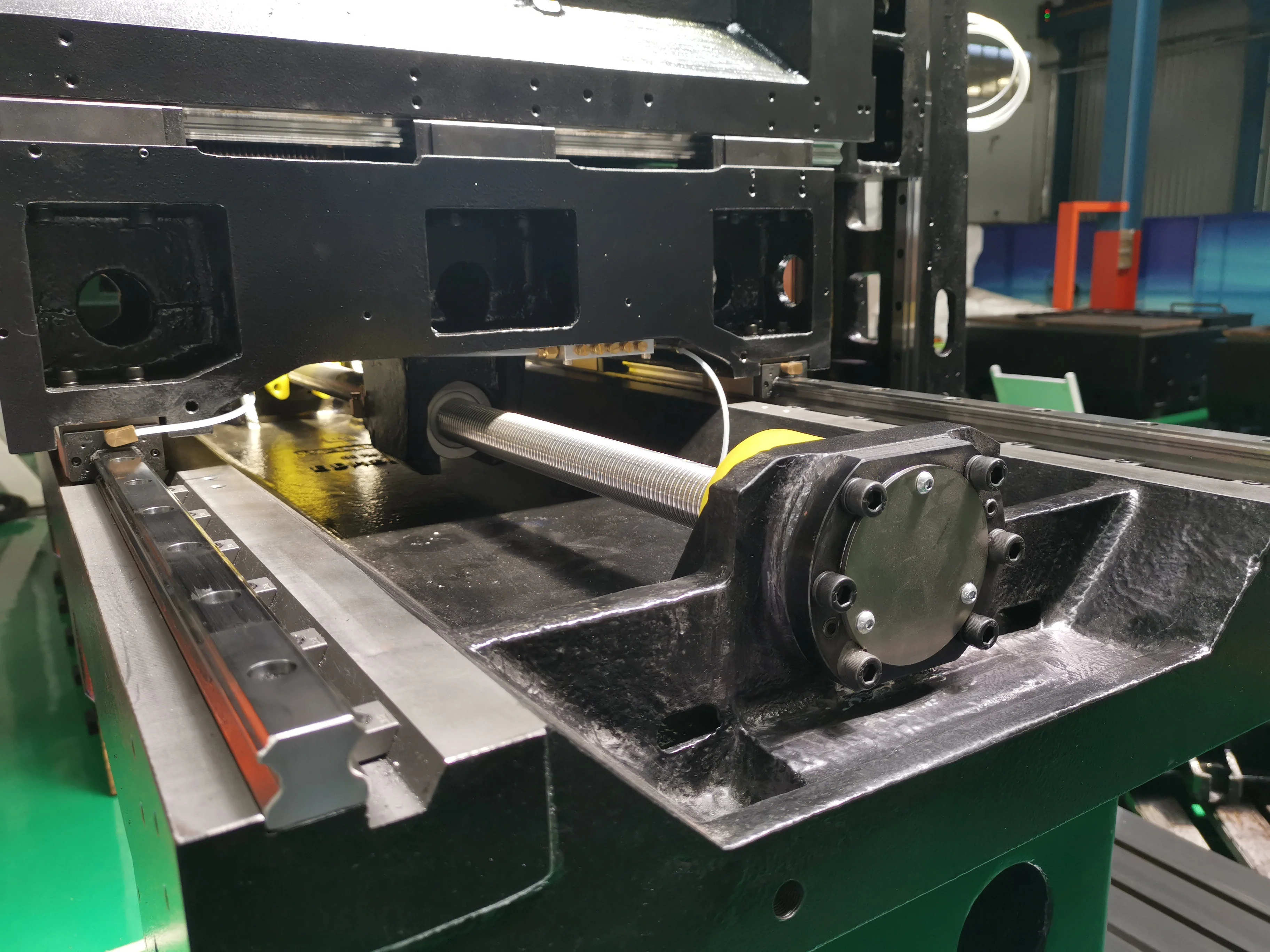

EDM машина CNC

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600233004050:

Описание и отзывы

Характеристики

Advantages of DMNC P40:

1.Excellent performance of both cooper and graphite electrode machining

2.Min machining current 0.1A

3.Best surface finish Ra≤0.12µm

4.Min. wear of electrode ≤0.1%

5. Positioning accuracy ≤0.01mm

6.Repositioning accuracy ≤0.05mm

Specification:

No. | Name | P40 |

1 | Working table dimension(L×W) | 700×400mm |

2 | X×Y×Z axis travel | 400×300×320mm |

3 | Working tank dimension(L×W×H) | 1200×680×440mm |

4 | Highest level of working liquid | 290mm |

5 | End of spindle to working table | 585mm |

6 | Capacity of oil tank | 590L |

7 | Max weight of electrode | 25kg |

8 | Max weight of workpiece | 400kg |

9 | Positioning accuracy | <10µm |

10 | Repeat positioning accuracy | <5µm |

9 | Weight of machine | 2600kg |

10 | Dimension of machine | 2572×2300×2335mm |

11 | General input | 9kVA(50A) |

12 | Input power | 3 Phase 380/50Hz |

13 | CNC power generator | A3-50 |

14 | Max working current | 50A |

15 | Best surface finish | Ra≤0.12µm |

16 | Min. wear of electrode | ≤0.1% |

17 | Max machining efficiency | ≥500mm3/min |

18 | Interpolation methods | Straight line, arc, helix |

19 | Accuracy compensation options | Step pitch compensation of each axis, gap compensation |

20 | Min. drive unit, Min command unit | 1µm |

21 | Outer dimension of controller | 1250×550×1800mm |

22 | Display | 15 inch touch screen |

23 | Remote control | different gradesMFR0-3 |

Functions of Controller:

No. | Function explanation |

1 | LCD, touch screen input |

2 | Simultaneous three axis control(optional 4-axis simultaneous control) |

3 | Super finish PIKA machining circuits-mirror surface machining function; excellent performance of corner clearing |

4 | Expert machining parameters database: with high explosive power circuit, specially good for processing hard alloy material) Automatic and manual machining according to different combination of different material of electrode and workpiece: copper/steel, graphite 1/steel, graphite 2/steel, silver-tungsten/steel, copper-tungsten/steel, silver-tungsten/hard alloy, copper/zinc alloy, graphite/zinc alloy, copper/copper alloy. |

5 | AUTO machining function: Input material of electrode and workpiece, machining area, shrinkage of electrode, required surface finish and etc Then control system automatically calculate machining parameters from rough machining to finish machining according to expert database. |

6 |

End face positioning, cylinder center positioning, corner positioning, inner hole positioning, random three points positioning, discharging position self-decided positioning and etc. |

7 | Utilize automatic positioning function to do online measuring and amending to machined workpiece. |

8 | Real-time monitoring on the discharging status, if any tiny short circuit or arcing happens, system would remove arcing and give alarm |

Parts Made by DMNC EDM Machine:

Marketing:

Professional Factory:

Strict Quality Control with Advanced Test Instrument:

Похожие товары

Счетчик давления с принтом газированных напитков разливочная машина для бутылок для газированной воды разливочная машина для бутылок

Горячая продажа экстракт травяной порошок экстракт семян грейпфрута экстракт грейпфрута нарингин 96%-98% порошок нарингина

Чистый натуральный органический жидкий экстракт семян грейпфрута по лучшей цене

Высококачественный чистый сок, грейпфрут, фруктовый порошок

Индивидуальный принт, высечка из высококачественной бумаги, игра IQ, пазлы для взрослых, 500 шт., 1000 шт.

Оптовая продажа, мягкая игрушка-антистресс из термопластичной резины

Черный перец хорошего качества

Новые поступления

Новинки товаров от производителей по оптовым ценам