EDM машины ZNC цена

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600235172071:

Описание и отзывы

Характеристики

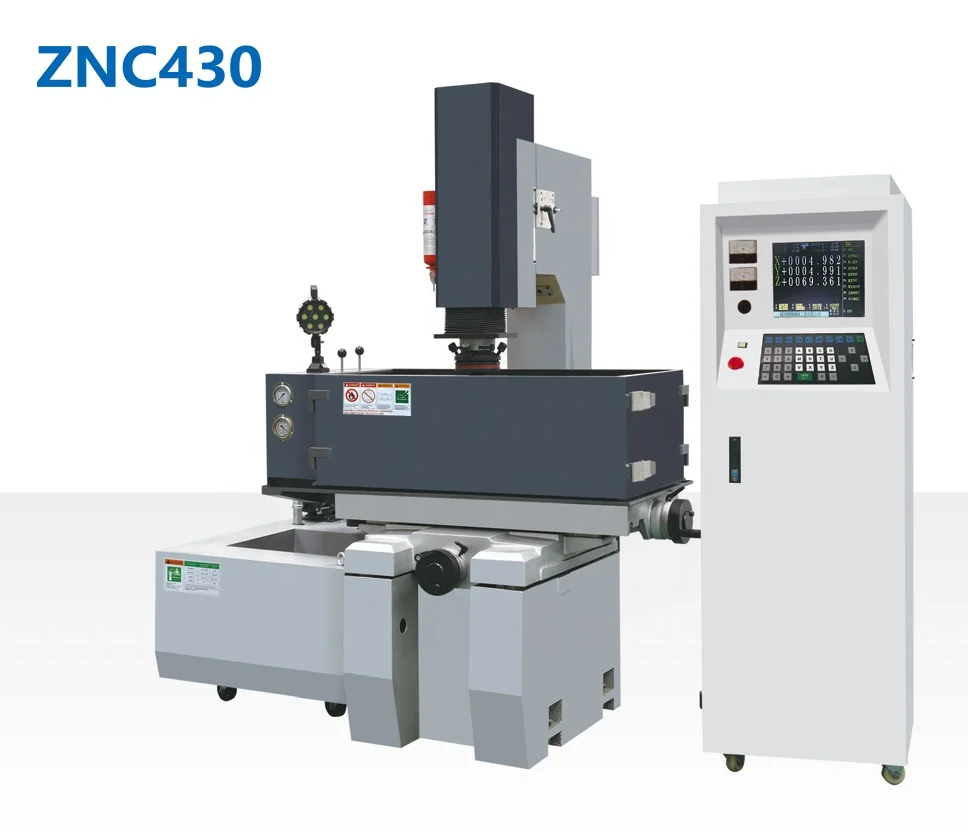

Advantages of ZNC350:

1.Original Taiwan C-Tek controller, LCD monitor, Industrial Computer Controller.

2.High accuracy X, Y, Z three axes C3 grade Taiwan made ball screw

3.Z axis imported Japanese Sanyo servo motor control

4.Three axes DROs of 0.005mm resolution

5.Resin sand casting as machine body and inner stress removed to make sure long-time rigidity and stability

6.Z axis is equipped with high precision roller guideway with Japanese SANYO DC servo motor, to make movement of Z axis more sensitive and smoother

7.Machine has wide machine base to make sure machine is strong enough of heavy loading, X and Y axis have V shape and flat guideway with FEFLON wear-resisting sticker, movement of heavy load is smooth and light, no crawling phenomenon.

8.Working lamp, fire extinguisher and lubrication unit, and patented electrode holder are all Taiwan made

9. More than 20,000 units of programming storage capacity. Normally, more than 20,000 different programming of mold or customer numbering can be stored

10.With mirror surface processing circuit, a true mirror effect can be performed. Furthermore, it is even better to use orbital processing and powder mixing processing

11.X, Y,Z axis coordinate are switch with Metric and English system

12. If machining is unstable, discharging condition is auto adjusted by modifying discharging efficiency and working time. After that, the condition will restore automatically. And it is also adjustable at any time.

Specification:

Items | unit | ZNC350 |

Oil load capacity of table | mm | 850×570×350 |

Table size | mm | 600×320 |

Travel of X/Y/Z | mm | 350×250×200 |

2nd Z axis travel | mm | 200 |

Distance from spindle end to table | mm | 150-550 |

Oil tank dimension | mm | 1000×1300×455 |

Max load of electrode weight | Kg | 50 |

Load of table | Kg | 50 |

Dimension of machine | mm | 1650×1400×2100 |

Net weight of machine | Kg | 1050 |

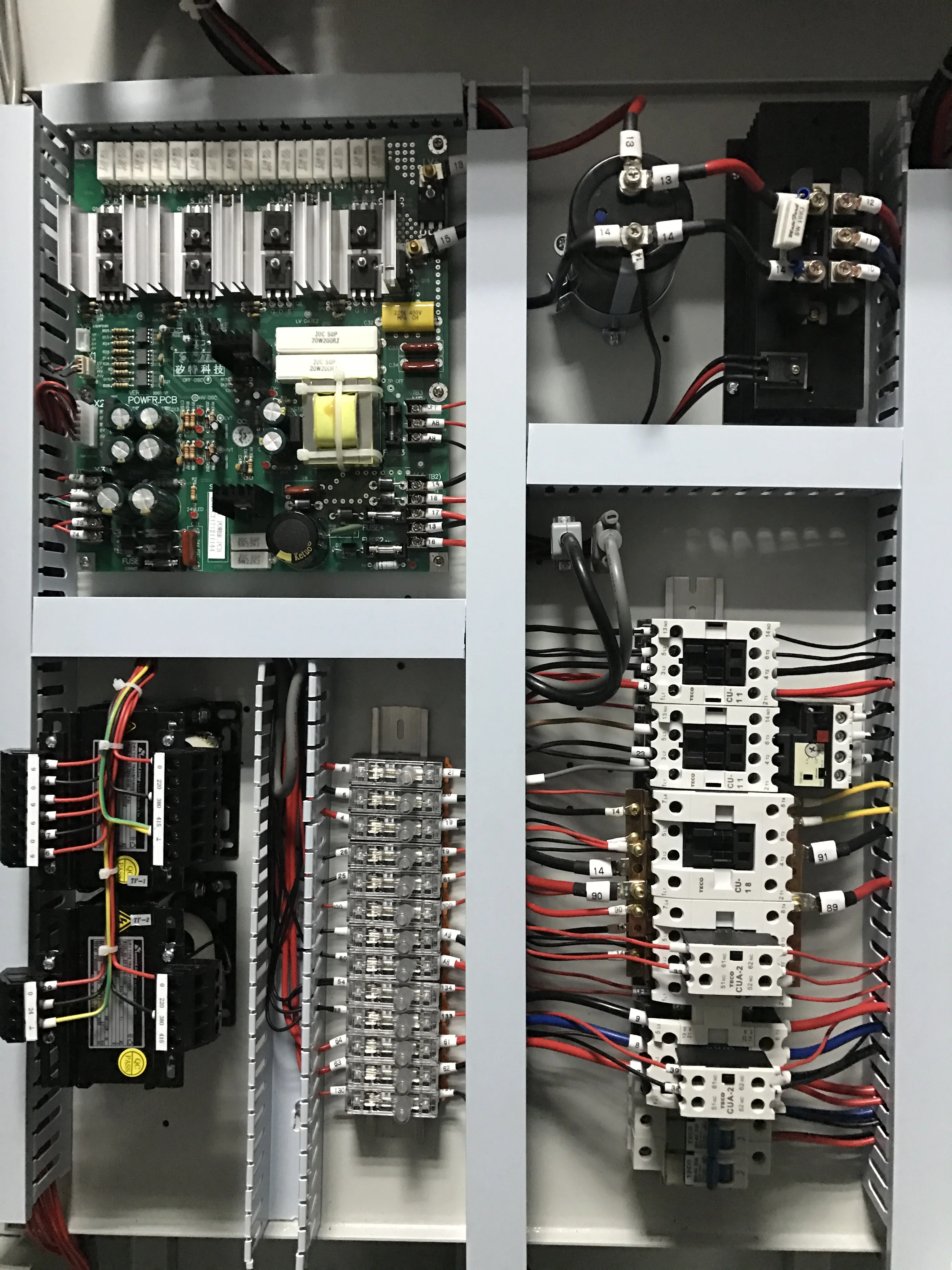

Power supply unit of ZNC controller:

Capacity | 50A | 75A | 100A | |

Control Method and Axes | Close Loop (Z-axis) | |||

Min. Setting Unit | 0.005mm(0.001mm) | |||

Max. Setting Unit | 9999.995mm(9999.9999mm) | |||

Coordinate System | INC,ABS | |||

Display System | 15"LCD | |||

Control System | PC BASED | |||

Inching | 0.005mm(Unit)×1, ×5, ×10 | |||

Data save | >10000 | |||

Max. Machining Current | A | 50 | 75 | 100 |

Total Power input | KVA | 4.5 | 6 | 10 |

Max. Material Removal Rate | mm3/min | 360 | 560 | 700 |

Electrode Wear Rate | % | <0.2 | ||

Best Surface Finish | μm | Ra 0.35(Ra0.2 with special circuits) | ||

Overall dimension | mm | 790×820×1850 | ||

Net weight | kgs | 260 | ||

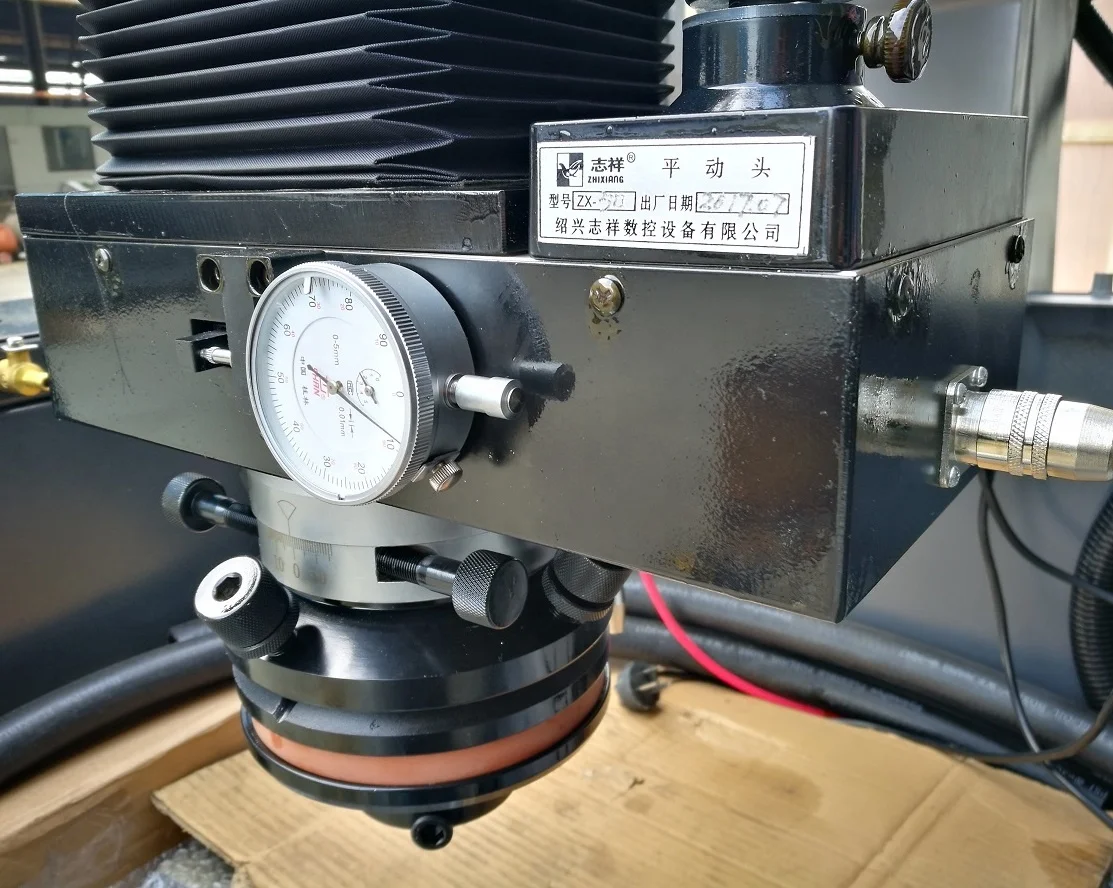

Professional Manufacturing Plant:

Похожие товары

EDM машина ZNC EDM машина цена

CNC проволочно-вырезной станок EDM машины ANT-WS 6D/8D профессиональный поставщик из Китая

Высококачественные автозапчасти 908024 XD3 XD3T 6190499 02.00.96 головка цилиндра для Ford For Peugeot 2498CC 2.5D L4 SOHC 8V 1986-

Высококачественная машина для резки проволоки с ЧПУ EDM, оснащенная проволочными шкафами управления edm

D7135 High precision Low Price CNC EDM DIE SINKER ZNC EDM Electric Discharge Erosion Machine

D71 Series Cnc Edm Die Sinker SparkErosion Edm Machine From Jiangzhou JZ Brand In China

Правительственный Сертифицированный производитель, торговая гарантия, хорошее качество, машина для резки проволоки из молибдена DK7780

Новые поступления

Новинки товаров от производителей по оптовым ценам