EDM аппарат Sinker зеркальный искрящий эрозионный станок CNC машина

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600236975152:

Описание и отзывы

Характеристики

Advantages of DMNC A30:

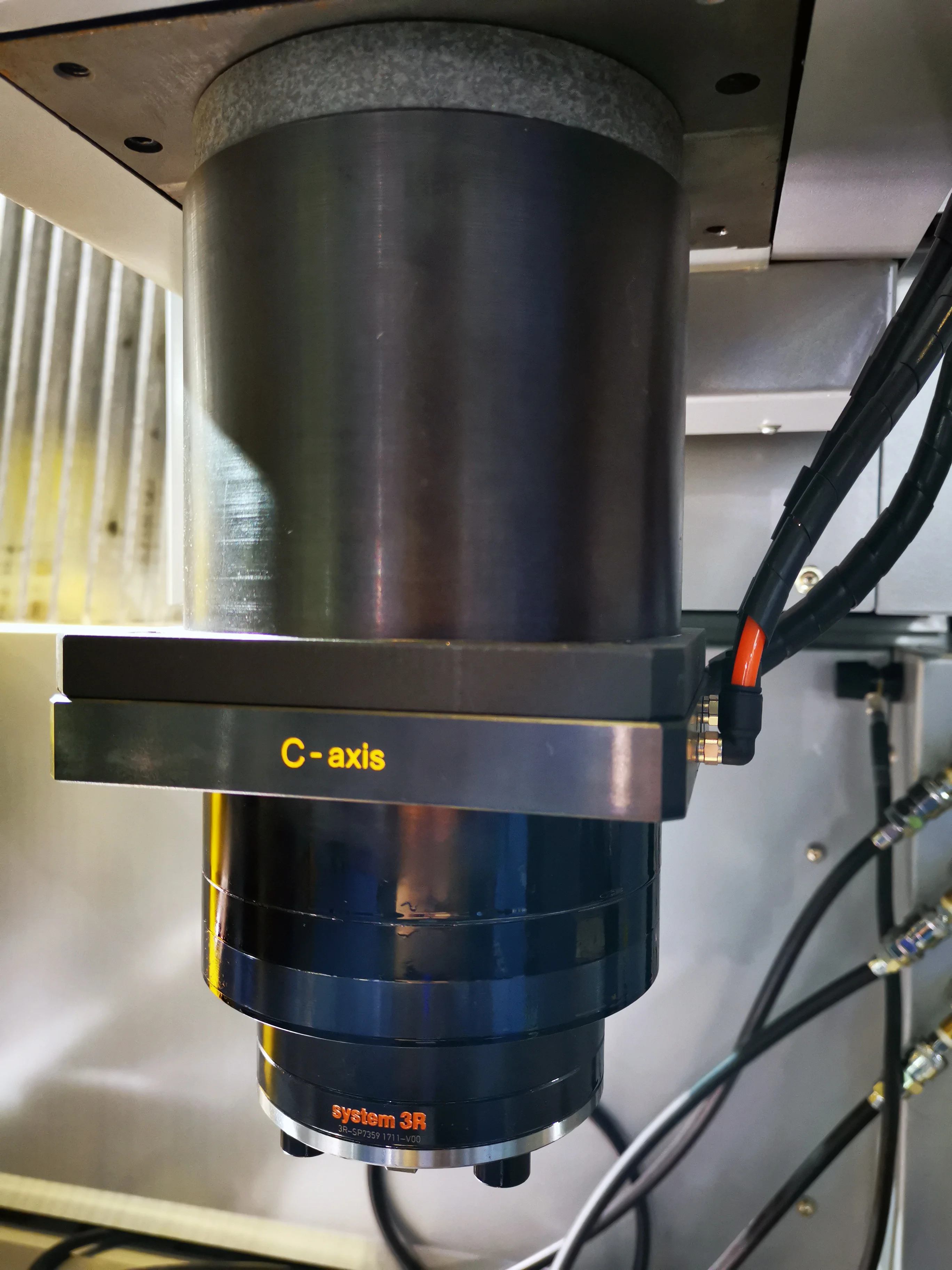

1.5th generation EDM machining control system

2.Smart expert database.

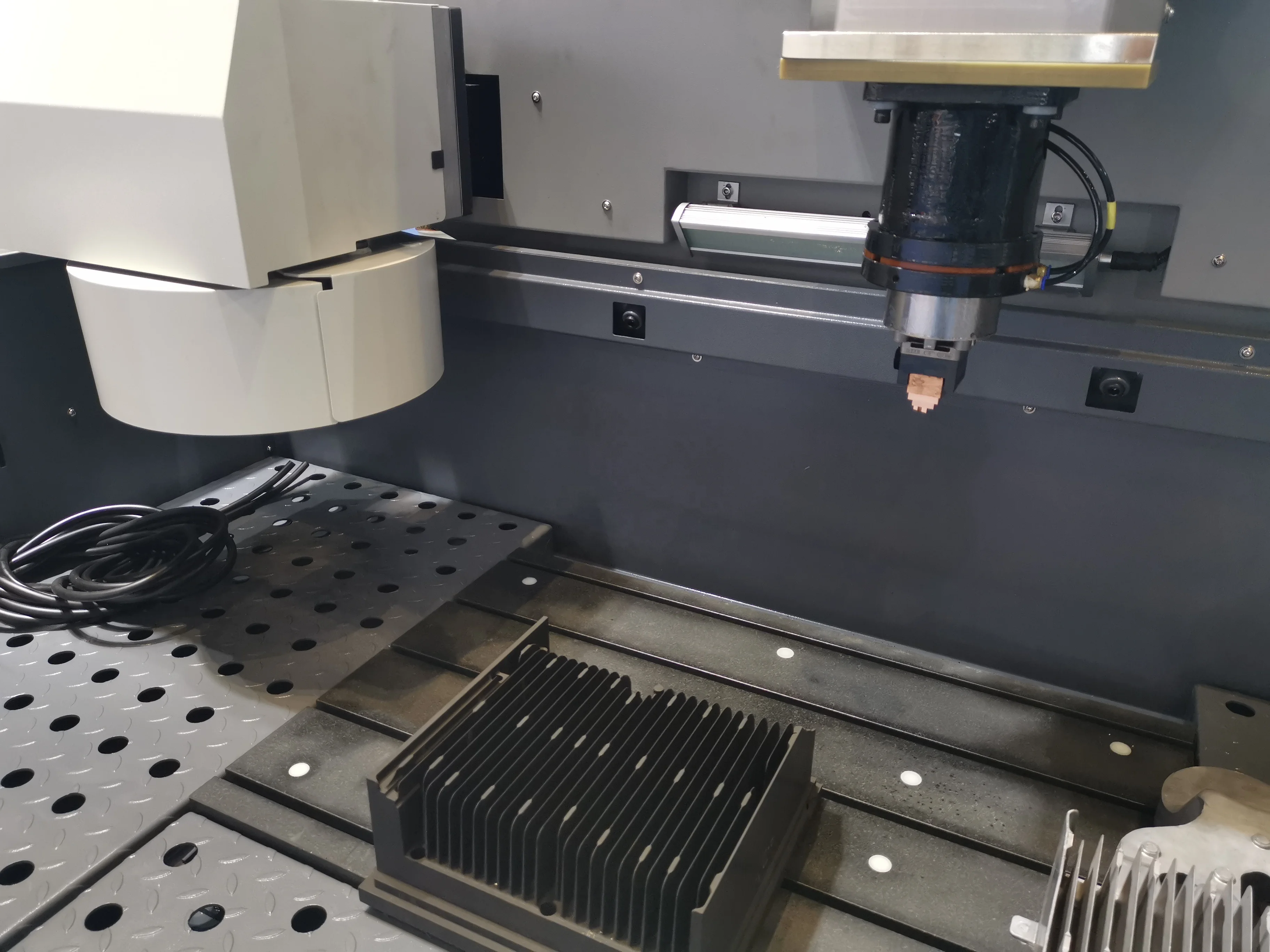

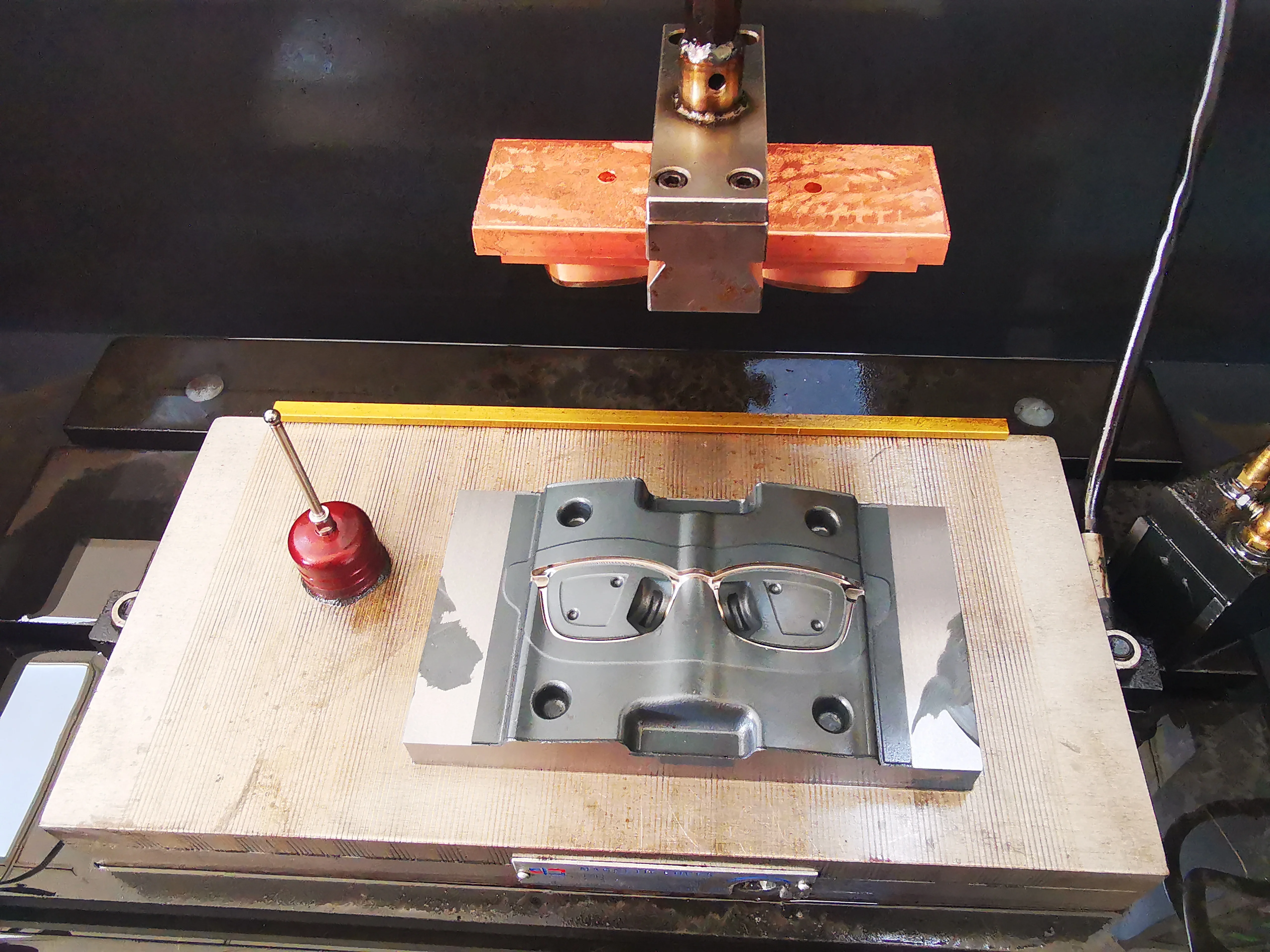

3.Excellent performance of both cooper and graphite electrode machining.

4.Min machining current 0.1A.

5.Best surface finish Ra≤0.08µm.

6.Positioning accuracy ≤6μm.

7.2 years aging treatment of casting of machine.

8.Obtained national design patent of rotary panel cabinet.

9.Man-machine engineering friendly.

10.Optimized high frequency power control system.

11.Most efficient control circuits.

12.Machine body had been analyzed by finite element analysis.

13.High quality casting with enhanced structural ribs.

14.Working table is made of high-lass marble(00 grade), barely no deformation due to change of temperature.

Specification:

No. | Name | A30 |

1 | Working table dimension(L×W) | 600×400mm |

2 | X×Y×Z axis travel | 300×212×272mm |

3 | Working tank dimension(L×W×H) | 990×640×410mm |

4 | Highest level of working liquid | 250mm |

5 | End of spindle to working table | 500mm |

6 | Capacity of oil tank | 500L |

7 | Max weight of electrode | 25kg |

8 | Max weight of workpiece | 400kg |

9 | Positioning accuracy | 6µm |

10 | Repeat positioning accuracy | 3.5µm |

11 | Weight of machine | 2000kg |

12 | Dimension of machine | 1380×1410×2250mm |

13 | General input | 9kVA(50A) |

14 | Input power | 3 Phase 220/60Hz |

15 | CNC power generator | A3-50 |

16 | Max working current | 50A |

17 | Best surface finish | Ra≤0.08µm |

18 | Min. wear of electrode | ≤0.05% |

19 | Max machining efficiency | ≥500mm3/min |

20 | Interpolation methods | Straight line, arc, helix |

21 | Accuracy compensation options | Step pitch compensation of each axis, gap compensation |

22 | Min. drive unit, Min command unit | 1µm |

23 | Outer dimension of controller | 1250×550×1800mm |

24 | Display | 15 inch touch screen |

25 | Remote control | different gradesMFR0-3 |

Parts Made By DMNC EDM Machine:

Professional Factory:

Strict Quality Control with Advanced Test Instrument:

Похожие товары

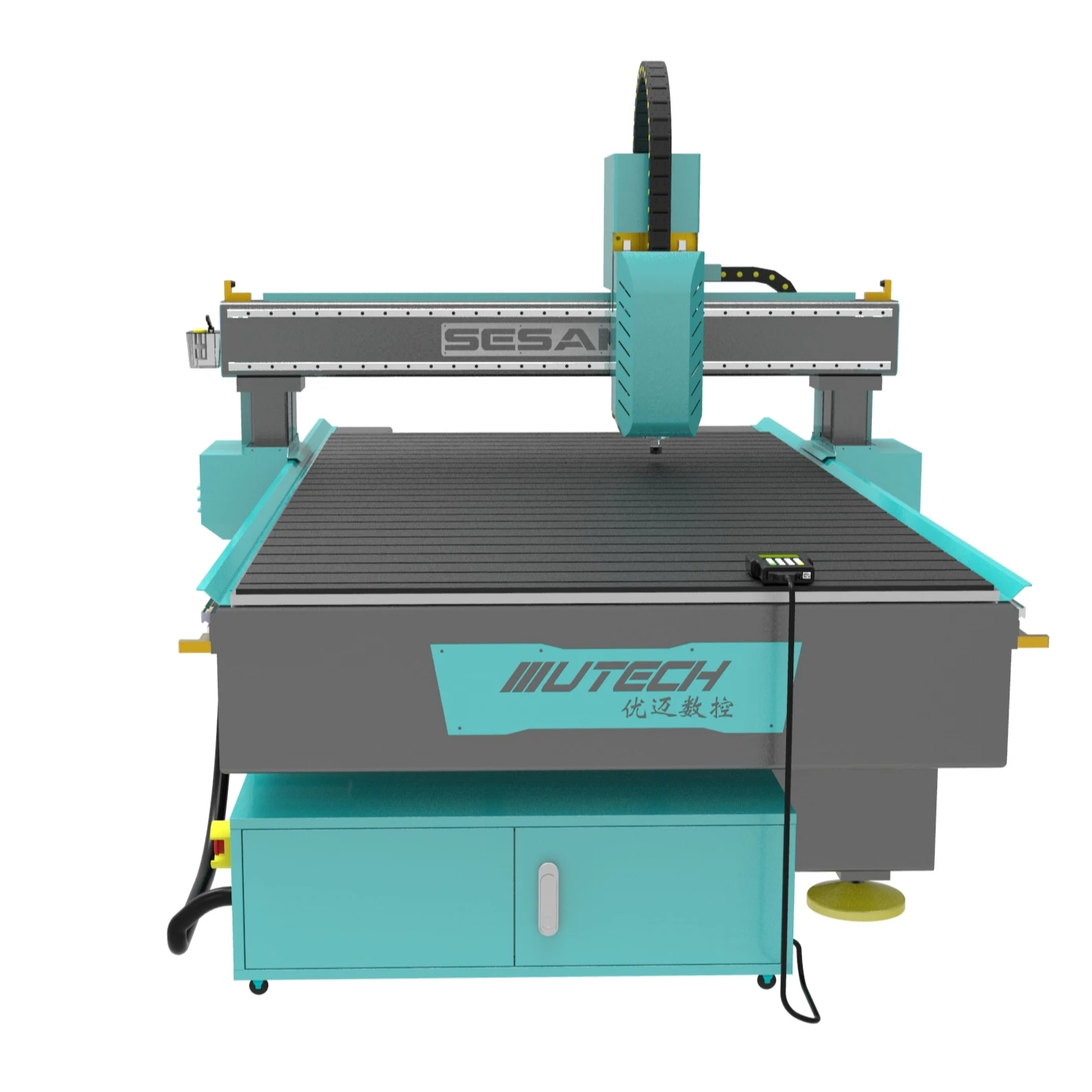

1212 1218 1224 1313 рекламный фрезерный станок с ЧПУ 3 оси/1218 автоматический 3d станок для резьбы по дереву/станок для резки по дереву

Низкая цена, тонущий Электроэрозионный станок с ЧПУ Sinker Edm

Автоматическая смена инструмента ЧПУ маршрутизатор 1325 ATC деревообрабатывающий режущий гравировальный станок

1325 cnc router machine for double color board China cnc wood router cnc router metal milling machine

Новый дизайн, гравировальный станок с ЧПУ для продажи, фрезерный станок с ЧПУ для продажи с сертификатом CE

NC DSP фрезерный станок с ЧПУ 1325 деревообрабатывающий гравировальный резной станок 3.2kw 4.5kw 5.5kw

2021 новый большой деревообрабатывающий станок 5x10 atc фрезерный станок с ЧПУ промышленный деревообрабатывающий гравировальный станок с ЧПУ

Новые поступления

Новинки товаров от производителей по оптовым ценам