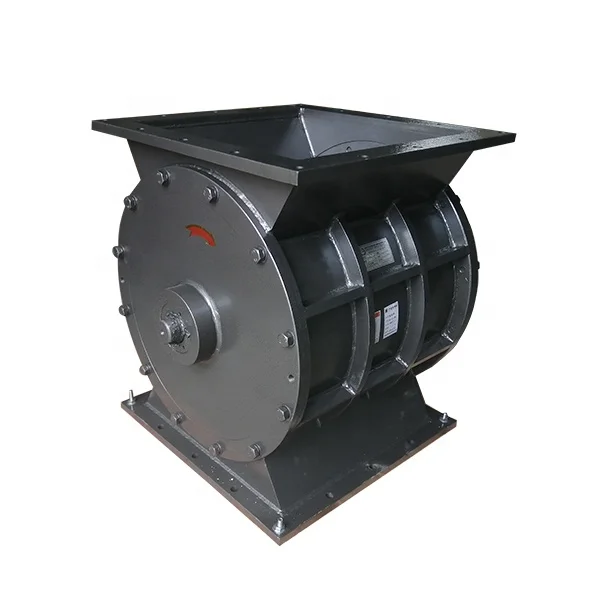

Разрядный клапан для золы корпуса риса

- Категория: >>>

- Поставщик: Chengdu Cheegers Grain Machinery Manufacturer Co. Ltd.

Сохранить в закладки 1600245543073:

Описание и отзывы

Характеристики

The flow-through rotary airlock (airlock discharge valve) is used in wide range of applications. The media enters from the top and exits from the bottom flange of rotary valve. This machine has exquisite appearance. It can separate the air and the media and calculate the production. It is usually connected under the cyclone and can control the flow rate of the media.

Used under the negative pressure conveying cyclone, hopper or silo. It is dedicated to supporting vertical mill feeding. This valve characterizes as good airlock performance to guarantee feeding uniformly and discharging smoothly. Plus no jamming, no material sticking, flexible rotor clearance and so on. Rotary airlock can handle materials like Flour ,Wooden chips ,Plastic ,Animal feed ,Sugar ,Cement ,Dust , Etc. This type of valve offers series connection solution, using single power to drive multi-valves. Ultimately, it can save energy and reduce purchasing cost.

System Craft Flow

Product Name | Rotary valve |

Conveying material | Powder and granule, particle |

Volume/rotation | 5L/T -140L/T |

Capacity( m³ ) | 2 T/h-- 200 T/ h &others |

Rotor speed(r/min) | 20-50 |

Rotor vane | 6-8 |

Temperature(°C) | <260° |

Clearance | ≥0.06mm |

Material | Stainless steel&carbon steel&cast iron |

Bearing | SKF |

Out-bearing | New type out-bearing |

Motor | SEW & others |

Power(kw) | 0.75-5.5 |

Drive arrangement | Straight connected / Chain drive |

Voltage | 380V \\ 415V & others |

Color | white\\blue\\green & others |

Advantage | Smooth surface,long service life,low noise,clog-free,easy installation and remove, precision finishing process. |

Application

| Silo emptying,cyclone discharging, dust collection systems, dosing, batching, mixing,pneumatic conveying applications, conveyor feeding / unloading, screw feeder feeding /discharging machinery and equipment feeding / power generation,bulk handing,etc. |

Industries served | Food, cement construction materials , agriculture, feed industry , chemical industry ,iron and steel industry , gypsum factories , environmental protection ,waste water treatment ,plastics PVC PP PE industry ,pulp and paper,dams, hydroelectric plants and pumping stations ,mining/slurry,air seperation,etc. |

Our products used for dry free-flow, hard-to-convey materials in pneumatic conveying system. The industries served as follows: food, baking, chemical, plastic, brewing, confectionery, mineral processing, petrochemical industry, etc.

Chengdu Cheegers Machinery Co., Ltd is rebuilt in 2003 from the revolution of China government factory CHIQI which was built in 1958. With continuous development and innovation, Cheegers has been the expert in producing mill feeding rotary valve, pneumatic distribution valve, diverter valve(two way valve), slide gate valve, and magnetic separator. Through long-term cooperation and communication with overseas manufacturer and clients, combining years of market experience, we offers solutions to solve and meet various bulk solids conveying demands for customers domestic and abroad.

Packaging Details:

1. The machine will be packed with the protect film inner and water-proof outside.

2. If the machine less than a container, wooden case packing is necessary.

3. The machine is fixed by steel roper in the container.

4. Others to make sure the machine is in good condition when arrived the destination.

Shipping Detail:

1. Arrange the machine within 30 days after your order be confirmed and received your deposit..

2. Arrange the shipment within 10 days after we received your full payments.

Q: Are you trading company or manufacturer ?

A: We are factory with over 60 years' professional reserach and development. We can provide the best price.

Q: What can we do if the product we received is different from your description?

A: If the product's quality is not consistent with description we described or the promise before, we promise 100% refund.

Q: How long is your delivery time?

A: Standard products are in stock, which takes a week to be ready for delivery. Non-standard valve takes 35 days for production.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 40% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Alina Zhang: 0086 133 7811 4072

Похожие товары

Микро-fitlter для Универсальный Топливная форсунка 6*3*12 мм CF-101 ASNU03

WOPOW LT-25 Самая низкая цена Быстрая зарядка кабель для передачи данных с разъемом type-c с изгибом кабеля

Ультрамягкий Мужской свитшот по индивидуальному заказу, новейший дизайн для мужчин разных размеров

Дешевый надувной стол для пива и понга

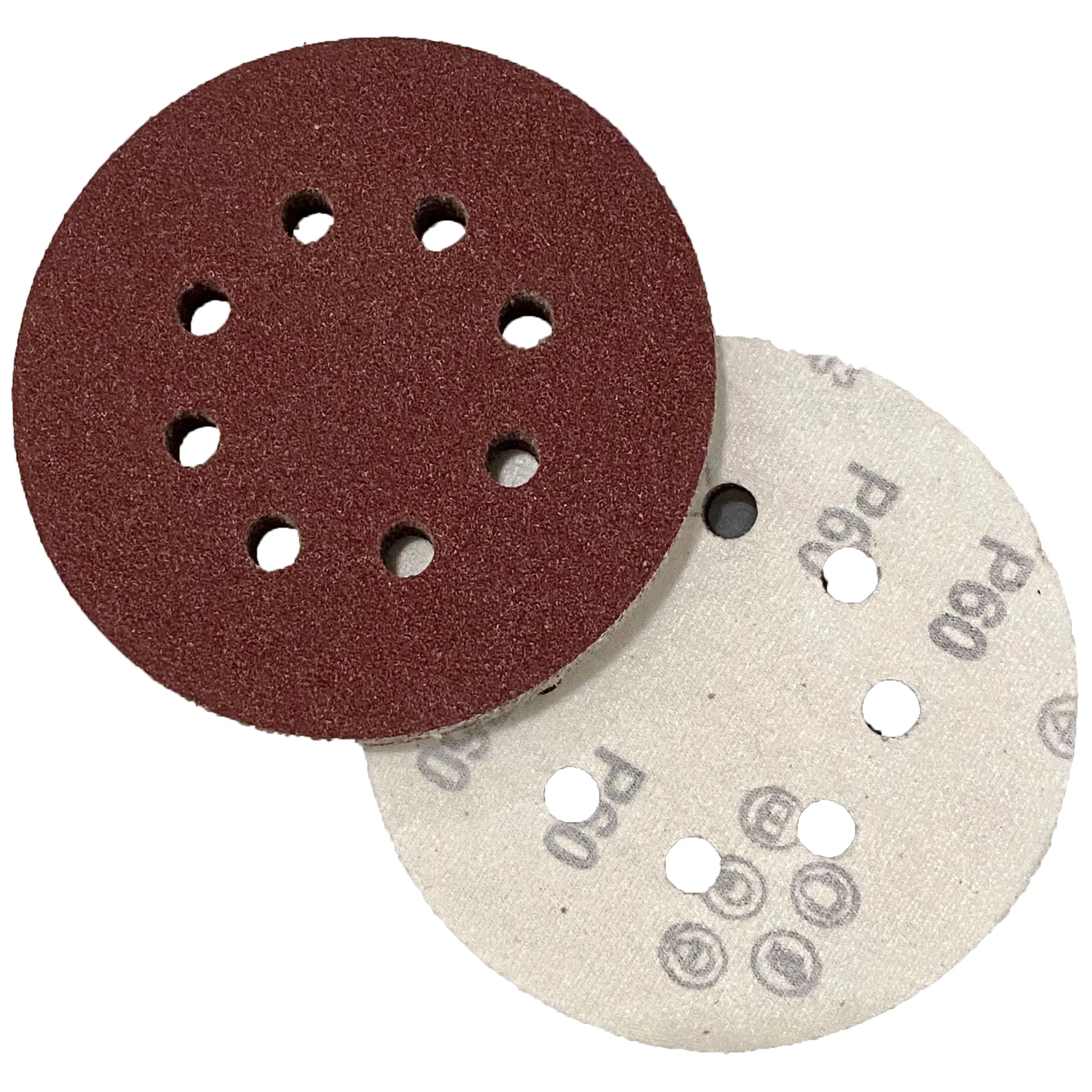

6inch 150mm germany aluminum sand paper raw material round sand paper for angle grinder sanding paper

Амортизатор A9063207630 для Mercedes Sprinter

Freeze Dried Papaya

Новые поступления

Новинки товаров от производителей по оптовым ценам