CNC EDM машина Sinker Die тонущий станок высокая точность

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600247208374:

Описание и отзывы

Характеристики

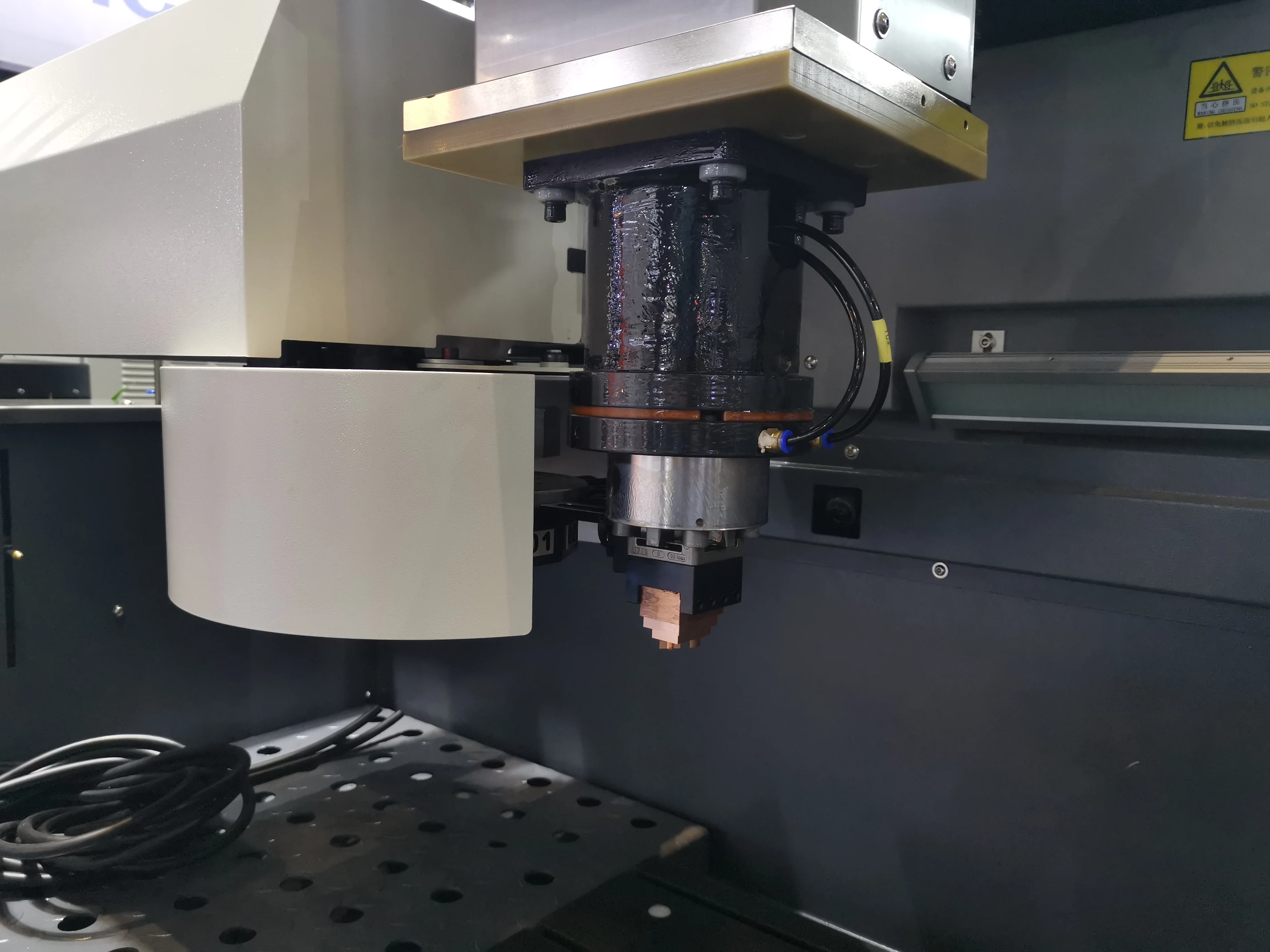

Advantages of DMNC ADI 500:

1.Latest 6th generation Windows platform control system

2.Up-and-down working tank door, same space, easy to handle.

3.Intelligent automatic EDM machining.

4.New expert database.

5.Excellent performance of both cooper and graphite electrode machining.

6.Multiple pages editing at the same time, no need to stop machining.

7.Min machining current 0.1A.

8.Best surface finish Ra≤0.2µm

9.Positioning accuracy ≤5μm

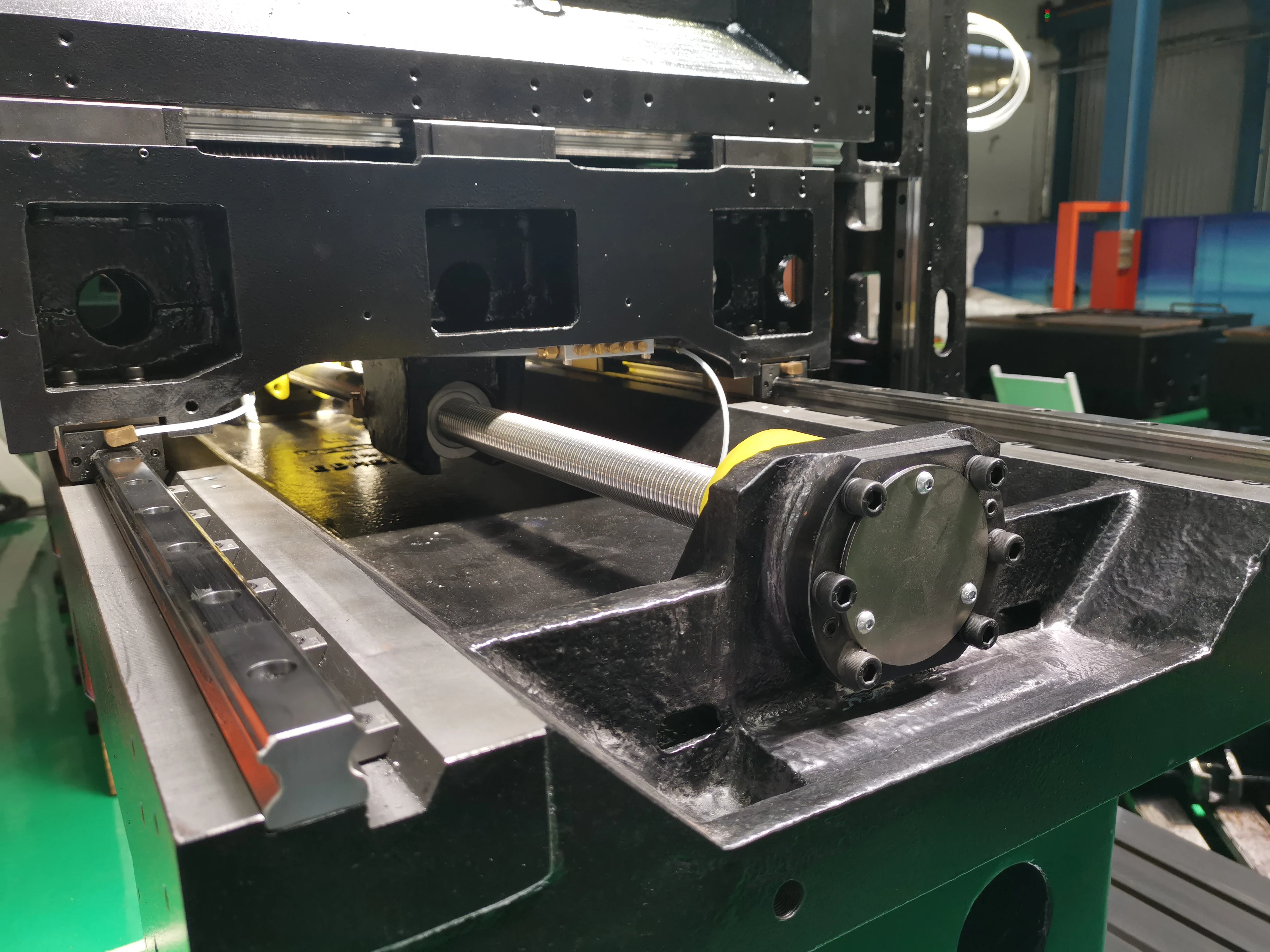

10.Imported SP grade linear guideway

11.C2 grade ball screw

12.3 years aging treatment of casting of machine.

13.High jump function, after serval times of regular jump discharging, Z axis move higher, and then goes with regular jump height again, it is help for deep groove and massive area machining.

14.Machining speed is about 30% faster than DOS platform discharging control system.

15.Auxiliary learning function

Specification:

No. | Name | ADI500 |

1 | Working table dimension(L×W) | 800×500mm |

2 | X×Y×Z axis travel | 500×400×300mm |

3 | Working tank dimension(L×W×H) | 1340×850×500mm |

4 | Highest level of working liquid | 350mm |

5 | End of spindle to working table | 700mm |

6 | Capacity of oil tank | 600L |

7 | Max weight of electrode | 80kg |

8 | Max weight of workpiece | 1800kg |

9 | Positioning accuracy | 5µm |

10 | Repeat positioning accuracy | 3µm |

11 | Weight of machine | 3300kg |

12 | Dimension of machine | 2540×2487×2480mm |

13 | General input | 9kVA(50A) |

14 | Input power | 3 Phase 380/50Hz |

15 | CNC power generator | Windows 7 based |

16 | Max working current | 50A |

17 | Best surface finish | Ra≤0.2µm |

18 | Min. wear of electrode | ≤0.1% |

19 | Max machining efficiency | ≥500mm3/min |

20 | Interpolation methods | Straight line, arc, helix |

21 | Accuracy compensation options | Step pitch compensation of each axis, gap compensation |

22 | Min. drive unit, Min command unit | 1µm |

23 | Outer dimension of controller | 1250×550×1800mm |

24 | Display | 15 inch touch screen |

25 | Remote control | different gradesMFR0-3 |

Functions of Controller:

No. | Function explanation |

1 | LCD, touch screen input |

2 | Windows intelligent expert platform CNC EDM control system |

3 | Multiple pages to be edit at the same time |

4 | Coordinate position automatic memory |

5 | Standard with simultaneous three axis control, Max six axis simultaneous control |

6 | Super finish PIKA machining circuits-mirror surface machining function, Min machining current 0.1A |

7 | Expert machining parameters database: with high explosive power circuit, especially good for processing hard alloy material) |

8 |

Input material of electrode and workpiece, machining area, shrinkage of electrode, required surface finish and etc Then control system automatically calculate machining parameters from rough machining to finish machining according to expert database. |

10 | Utilize automatic positioning function to do online measuring and amending to machined workpiece. |

Parts Made By DMNC EDM Machines:

Professional Factory:

Похожие товары

DK7735 быстрое Перемещение cnc edm машина для резки проволоки DK7735

Китайский производитель, выполненный напрямую, алюминиевый Тепловой разрыв, раздвижная дверь с большой панелью и Сверхпрочной конструкцией

Воздушный шар из алюминиевой пленки с героями мультфильмов, Хэллоуин, шампанское, ведьма, призрак, летучая мышь, тыква, призрак, мессенджер, украшения для праздника, вечеринки

Мыло большого размера для африканской страны, дешевое и существенное мыло.

Пленочный принтер для разных текстильных изделий, большой цвет, 30 см, принтер DTF A3 для домашнего использования «сделай сам», dtg, принтер для текстиля с шейкерной машиной

Трехцветные Металлические Лопасти/сохраняйте ваши вертикальные жалюзи оптом онлайн

Автоматическая упаковочная машина KEFAI для большого количества порошков и удобрений для химической промышленности

Новые поступления

Новинки товаров от производителей по оптовым ценам