Высокоточная машина EDM тонущий станок Sinker Machine

- Категория: >>>

- Поставщик: Taizhou Taisen Electromechanical Co. Ltd.

Сохранить в закладки 1600248077098:

Описание и отзывы

Характеристики

Advantages of DMNC ADI 1800:

1.Latest 6th generation Windows platform control system

2.Up-and-down working tank door, same space, easy to handle.

3.Intelligent automatic EDM machining.

4.New expert database.

5.Excellent performance of both cooper and graphite electrode machining.

6.Multiple pages editing at the same time, no need to stop machining.

7.Min machining current 0.1A.

8.Best surface finish Ra≤0.2µm

9.Positioning accuracy ≤5μm

10.Imported SP grade linear guideway

11.C2 grade ball screw

12.3 years aging treatment of casting of machine.

13.High jump function, after serval times of regular jump discharging, Z axis move higher, and then goes with regular jump height again, it is help for deep groove and massive area machining.

14.Machining speed is about 30% faster than DOS platform discharging control system.

15.Auxiliary learning function

16.Double heads with two separated controllers to conduct two separated machining at the same time.

Specification:

No. | Name | ADI 1800 |

1 | Working table dimension(L×W) | 2000×1000mm |

2 | X×Y×Z axis travel | Each head 1200×800×600mm |

3 | Working tank dimension(L×W×H) | 3500×1800×650mm |

4 | Highest level of working liquid | 600mm |

5 | End of spindle to working table | 1100mm |

6 | Capacity of oil tank | 4000L |

7 | Max weight of electrode | 250kg |

8 | Max weight of workpiece | 7000kg |

9 | Positioning accuracy | 5µm/300mm |

10 | Repeat positioning accuracy | 3µm |

11 | Weight of machine | 15000kg |

12 | Dimension of machine | 5340×5250×3930mm |

13 | General input | 9kVA(50A) |

14 | Input power | 3 Phase 380/50Hz |

15 | CNC power generator | Windows 7 based |

16 | Max working current | 50A |

17 | Best surface finish | Ra≤0.2µm |

18 | Min. wear of electrode | ≤0.1% |

19 | Max machining efficiency | ≥500mm3/min |

20 | Interpolation methods | Straight line, arc, helix |

21 | Accuracy compensation options | Step pitch compensation of each axis, gap compensation |

22 | Min. drive unit, Min command unit | 1µm |

23 | Outer dimension of controller | 1250×550×1800mm |

24 | Display | 15 inch touch screen |

25 | Remote control | different gradesMFR0-3 |

Functions of Controller:

No. | Function explanation |

1 | LCD, touch screen input |

2 | Windows intelligent expert platform CNC EDM control system |

3 | Multiple pages to be edit at the same time |

4 | Coordinate position automatic memory |

5 | Standard with simultaneous three axis control, Max six axis simultaneous control |

6 | Super finish PIKA machining circuits-mirror surface machining function, Min machining current 0.1A |

7 | Expert machining parameters database: with high explosive power circuit, especially good for processing hard alloy material) |

8 |

Input material of electrode and workpiece, machining area, shrinkage of electrode, required surface finish and etc Then control system automatically calculate machining parameters from rough machining to finish machining according to expert database. |

Parts Made By DMNC EDM Machines:

Professional Factory:

Похожие товары

SKD CKD 600 Вт 800 Вт мотовелосипед Электрический мотоцикл 40-50 км/ч скорость 45-65 км Диапазон eec 10 дюймов электрический мопед со съемным аккумулятором

Низкая цена, гарантированное качество, популярный продукт, умный наружный замок, дверной замок для умного дома

Удобные дышащие охлаждающие простыни для отелей набор роскошных простыней из мягкой микрофибры 4

MJL ASSY-WHITE бар CIS, M4580,SEC датчик DL620-01UHS-C для Samsung m4580 M4080 M2680 M6030 4080 2680 6030 SL-ML4580FX головка ADF

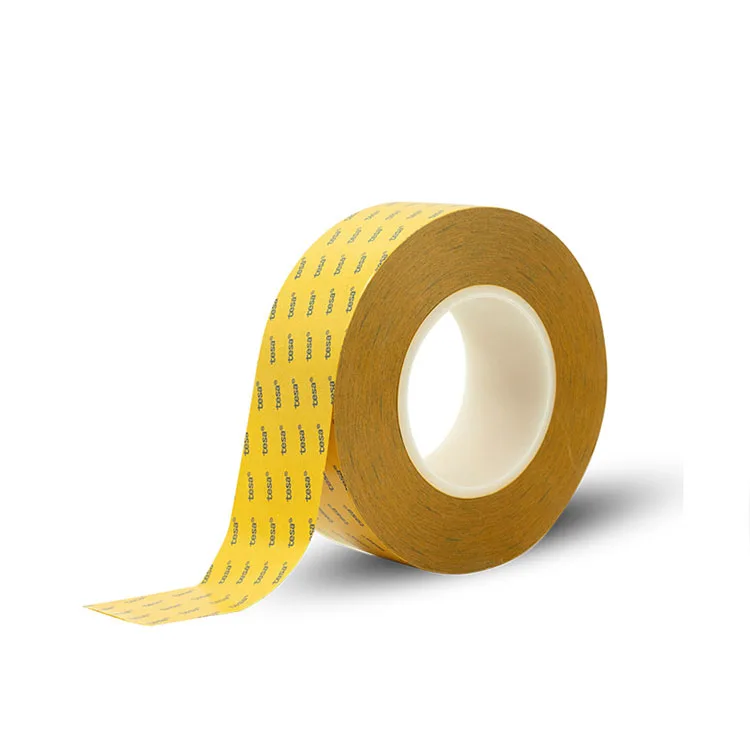

Многофункциональная акриловая лента Tesa VHB tape ACX Plus 7282 7283

Браслеты из натурального сандалового дерева с бисером Будды для мужчин и женщин, 108 молитвенные 4-слойные браслеты на запястье с китайским узлом, подарок

Tesa 4972 0,048 мм прозрачная двухсторонняя лента с высокой вязкостью двухсторонняя лента

Новые поступления

Новинки товаров от производителей по оптовым ценам